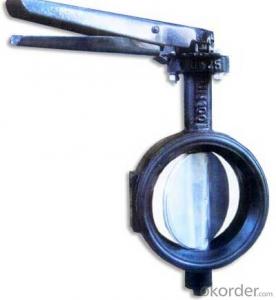

Slim Disc Wafer Butterfly Valve Cast Iron / Ductile Iron Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Slim Disc Wafer Butterfly Valve Cast Iron / Ductile Iron Material

About Product

1. Small in size and light in weight; Easy installation and maintenance; It can be mounted wherever needed

2. Simple and compact construction, quick 90 degrees on-off operation.

3. Minimized operating torque, energy saving.

4. Bubbles-tight sealing with no leakage under the pressure test.

REASONS FOR CHOOSE US

1.We are direct proucer of butterfly valves, check/non-return valves, gate valves and so on.

2.We can offer you most professional technical support.

3.All valves are tested twice before and after hammer pin to ensure its perfect sealing property.

4.Valves' back seats are phenolic resin under DN350 while above DN400 are aluminium back seat to prolong its working life.

5.Concentric valves can ensure zero leakge.

- Q: Where is the filling portion of the valve?

- The valve stem and the body of the valve at the junction of the pressure cap, the pressure cap is filled inside.

- Q: What is the difference between valve j941H-40 and j41H-40?

- The difference is that one drive is electric, one is transmission, and the other is manual."Valve design manual" showsJ- stop valve9- electric4- connection means flange connection1- through typeH- sealing surface is alloy40- operating pressure is 4.0Mpa (or 40 kg)More than one, 9, 9 fingers, electric, more than an electric.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: the valve to an electrical signal, with this signal to control other components, ask: what valve?

- Online search "air switch", many suppliers.You may choose your pipe according to your pipe diameter.The flow meter can also be used to control the flow of operation

- Q: What are the specifications of the valves PN25, DN50?

- Upstairs professional level can be seen very solid.... Clap your hands... Popular speaking, that is, the valve bore is 50, resistance to pressure is below 25, is no problem.

- Q: How do you calculate the valve wall thickness, pressure, and other valve design calculations in a spreadsheet?

- For you to introduce the spreadsheet calculation, application basis, you according to this principle for valve correlation calculation:When A1 and B1 cells are used as parameters, the amount of computation is calculated by C1. If the formula is X+Y=? In the A1 cell, fill in the X; fill the Y in the B1 cell; fill in the C1 cell with "=A1+B1"; enter the carriage, and then calculate the corresponding value in the C1 cell. For example: fill in 5 in the A1 cell; fill in 8 in the B1 cell; enter the carriage, and then appear in the C1 cell 13. Other calculations are the same, you will calculate the valve formula, such as the above fill in, given the corresponding parameters, the same can be calculated.

- Q: According to the original valve installed on it, but never demolished, I am afraid to force over, will not be broken? The old valve, that part of the remaining three tubes tight.

- The new spool to buy off, installed in the old spool that. You don't have the same brand. You may not be able to load it. It's better to have the same brand

- Q: How to check the quality of the valve?

- First, visual inspection of the valve appearance, followed by a spectrometer to check the material, material, and then look at the hydraulic test pressure, whether there is leakage.

- Q: What does valve DN50/80 mean?

- DN50/80 refers to the size of the valve. That is, the circulation diameter is 50mm/80mm.

- Q: What valve is the YQZ45X-16Q?

- Specifically, YQ usually is the enterprise code, Z valve, 4 representative flange, 5 representatives of the dark bar, X (soft) rubber seal (gate coated with rubber material), nominal pressure 16 representative (PN) 1.6Mpa, Q on behalf of the valve body is made of ductile cast iron. If you add the valve bore (DN), it will be more detailed.

- Q: What is the diameter of a general pipe valve?

- In fact, the essence of the problem is the corresponding relationship between the nominal diameter and other dimensioning methods. Valves are generally marked with nominal diameter (DN***), such as DN150, DN100 and so on. There are many kinds of marking methods for pipes, such as outer diameter, inch inch, nominal diameter, etc.. Only when the other dimensioning is converted to nominal diameter, the valve and the pipe correspond to each other.

Send your message to us

Slim Disc Wafer Butterfly Valve Cast Iron / Ductile Iron Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords