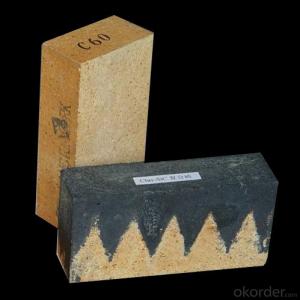

High Alumina Brick Silicon Nitride Bonded Silicon Carbide Products - Beam Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon nitride bonded silicon carbide produced by the beam, used in tunnel kiln, shuttle kiln, down draft kiln, has good carrying capacity, to increase the yield of full use of kiln furnace space, the selection of silicon nitride bonded silicon carbide, is the ideal kiln furniture, also can choose the upright post support frame for.

Advanced Refractory Materials Factory,with annual output 36000 tons, is the world's largest nitride bonded silicon carbide products production base ,and with import foreign advanced technology and key equipments, is the national unique factory with high-temperature and high-pressure Nitrogen furnace and frequency modulation and amplitude modulation vibration shaping equipment, which fully insure best quality of advanced refractory materials ,so we can fully guarantee thickness in the 90-450 mm, thick products between the quality of products

Mainly products as super refractory materials Si3N4-SiC, which is the substitute for the traditional Si3N4-SiC, and Sialon-Sic, Sialon-Corundum, Corundum-Mullite, Corundum-Mullite-SiC etc. And other unshaped refractory materials For the those kind of materials with characteristic of high temperature resistance, better wear resistance, better thermal shock resistance, better alkali and acid corrosion resistance, and better chemical stability, perfect and homogeneity for Micro-structure, and better thermal conductivity, which promote materials good properties, and widely used in high temperature industry as followed:

1. Being lining materials of high-temperature furnace (lower stack, bosh, belly, and ceramic cup of furnace chamber, and tuyere and tap-hole combined bricks)

2. Being sidewall of aluminum electrolytic cell, heating furnace chamber of aluminum melting furnace and pipes for aluminum liquid transportation.

3.Being high-temperature and wear resistance, alkali and acid corrosion resistance protective materials in Petrochemical industry, rubbish burning furnace, electricity-generating boiler, and heating furnace.

4. Being furnace tools (like Batts, baffles, columns, Sandwiched Plates, Bowl and work holders) under high and super high temperature in Alumina ceramics products, Ceramics, grinding wheel, electric ceramics, sanitary, and fine ceramics, and magnetic materials.

5. Being CFB boiler lining and pipe protective materials of corrosion resistance.

6. Being lining for high temperature furnace, slurry pump, coal ash slurry pump, and mine slurry pump etc.

7. Being all kinds of unshaped refractory materials and fireclay of high temperature industrial furnace

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- In short, the overall market of refractory enterprises is in a turbulent adjustment process, but the volume is still in place. Elimination is inevitable, as to how many can be eliminated, dare not assert.

- Q: Introduction of high alumina brick

- Three alumina silicate refractory product with a content of two Al2O3 (48%).

- Q: What is the difference between corundum and high alumina??

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: What are the common thermal insulation materials for thermal conductivity?

- The single organic insulation material should be the best polyurethane in the field. In accordance with the production process can be divided into on-site foam polyurethane and factory prefabricated rigid foam polyurethane board. The scene is polyurethane foam isocyanate and polyol to cool (polyether or polyester) two components as the main raw materials with additives, the on-site spraying construction with thermal insulation and waterproof function of the rigid foam material.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Hello Only on behalf of the Zhengzhou colt as refractory product index your answer to this question is not entirely separate from the chemical index of aluminum content, silicon content and judgment, personally think that three types of refractory bricks may respectively is: Two: semisilica brick high alumina brick

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The rotary kiln lining structure of rotary kiln and requirements on refractories calcining active lime according to the general output is divided into Nissan 300t, 400 t, 600 t, 800 t, 1000 t, 12000 t of kiln type, calcining zone temperature at 1350 degrees celsius. The kiln is divided into a discharge end, a cooling zone, a burning zone, a preheating zone and a feeding end, and the temperature of each section of the kiln ranges from 1000 DEG C to 1350 DEG C, and the requirements for refractory materials are different. The kiln refractory materials not only to withstand the high temperature impact, but also need to bear the material erosion, kiln rotation stress produced, so not only on the physico-chemical properties of refractory materials have strict requirements, but also for the construction of brick should be strictly.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Because the hot air outlet of the top burning hot blast furnace is high, the installation requirement of the hot air manifold is high, and the requirement of the strength of the pillar structure is higher, so the rectangular arrangement of the hot blast stove is arranged. The top burning hot blast stove is located on the furnace top because of burner and hot air valve,Therefore, operation, maintenance and installation all require mechanization and automation. Also, because these water cooled valves are mounted with a high elevation,Therefore, the demand for cooling water supply pressure should be improved accordingly, the use of large top burning hot blast stove, the key lies in the design of high-power high-efficiency short flame burner. The top combustion hot blast furnace absorbs the advantages of internal combustion and external combustion hot blast stoves, and overcomes some of their shortcomings,Its structure can meet the requirements of modern blast furnace for high temperature, high pressure and large scale development,Combustion capacity, while meeting production requirements, has been successfully reduced by many devices,

Send your message to us

High Alumina Brick Silicon Nitride Bonded Silicon Carbide Products - Beam Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords