Silica Refractory Bricks for Coke Oven - Best Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction:

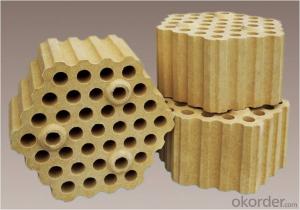

Silica Brick for Coke Oven is a siliceous refractory product used for building a coke oven with a quartz crystal as the main phase. The modern silicate brick coke oven is a large-scale thermal equipment built by tens of thousands of tons of nearly 2,000 kinds of brick-type refractory materials, in which the amount of silicon brick used in coke oven accounts for 60% to 70%. Coke oven silica bricks are used to build regenerator walls, chutes, combustion chambers, carbonization chambers and furnace roofs of coke ovens.

Silica Bricks For Coke Oven Application

1.Coke oven silica bricks are used to build chutes

2.Coke oven silica bricks are used to build regenerator walls.

3.Coke oven silica bricks are used to build combustion chamber

4.Coke oven silica bricks are used to build carbonization chambers

5.Coke oven silica bricks are used to build furnace roofs of coke ovens.

Technical Data:

Coke Oven After Repairing

Company Information

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.

- Q: What role does silica play in refractories?

- The production of clay brick refractory clay raw material is natural, its main mineral is kaolinite (formula Al2O3 - 2SiO2 - 2H2O), clay brick containing SiO2 in 45% ~ 65%, belongs to the weak acid refractory materials, have a certain ability to resist acid slag, but easy to be alkaline slag erosion.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: Brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

Send your message to us

Silica Refractory Bricks for Coke Oven - Best Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches