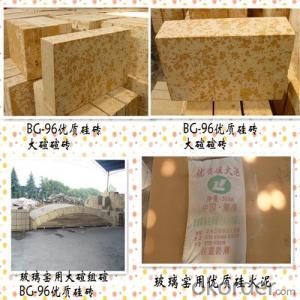

Silica Brick Reinforced Rubber Carbon Black Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Rubber carbon black bricks

1.Mature Professional Operation

2.Wet Granular

Rubber carbon black bricks

Product name:carbon black

Molecularformula: C

CAS No.:1333-86-4

EINECS No.: 215-609-9

Usage: Maily used in various rubber products such as tyres, rubber overshoes, cable, seal ring, tape etc. Also can be used in relevant industries such as plastic manufacutre.

It is mainly used for rubber intensifier and packing, its consumption is about half of rubber rubber consumption of carbon black with carbon black 94% of the total, with approximately 60% for tyre manufacture. In addition, also used for printing ink, paint and plastic colorants and plastic products BingBiJi of ultraviolet light, as well as important fertilizerFor many other products, such as electrode, dry, resistors, explosives, cosmetics, and polishing compound.

Grade:N220/N330/N550/N660 etc.

1) N220

Wear and the anti-cracking N110 compared with high, set out low stress, dispersivity is good.

2) N330

It with good abrasion resistance and medium hysteresis.

3) N550

It in soft carbon black varieties has the best reinforcing performance, excellent extruding performance, low resilient rate.

4) N660

It compared with N550, reinforcing the gender is low, the structure is lower, higher inflation, mouth filling quantity is bigger.

Specification:

ITEM | N220 | N330 | N550 | N660 |

Iodine Absorption Number, g/kg | 121 +/-5 | 82 +/-5 | 43 +/-4 | 36 +/-4 |

DBP Absorption Number, 10-5m3/Kg | 114 +/-5 | 102 +/-5 | 121 +/-5 | 90 +/-5 |

DBP Absorption Number of Compressed Sample, 10-5m3/Kg | 93~107 | 81~95 | 81~95 | 68~82 |

CTAB Surface Area, 103m2/Kg | 106~116 | 79~87 | 38~46 | 31~39 |

Nitrogen Surface Area, 103m2/Kg | 114~124 | 78~88 | 38~46 | 30~40 |

Tint Strength | 110~120 | 98~108 | - | - |

Heating Loss, %≤ | 3.0 | 2.5 | 2.5 | 1.5 |

Ash, %≤ | 0.5 | 0.5 | 0.5 | 0.5 |

Tensile Strength Map, MPa≥ | -0.8 | -1.5 | -3.5 | -3.5 |

Extension, %≥ | +10 | -10 | -10 | +10 |

Map Modulus at 300%, MPa | -2.5 +/-1.3 | -1.7 +/-1.3 | -1.7 +/-1.3 | -3.5 +/-1.3 |

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: The chemical composition of silica brick and its physicochemical index?

- ????Al2O3 SiO2??????fe2o3??????cao???????r2o93~98?0.5~2.5?;;?0.3~2.5??0.2~2.7;??1~1.5;

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

Send your message to us

Silica Brick Reinforced Rubber Carbon Black Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords