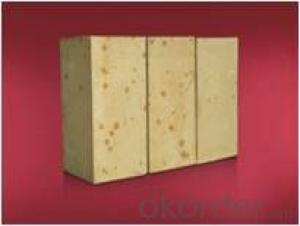

Silica Brick - Refractory Acid Resistance for Furnace Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

The silica brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In metallurgy industry, it is adopted as the nozzle brick

Features

1.High purity

2.Long service life

3.Accurate size tolerance

4.Pure color

5. Luster appearance

6..Good thermal conductivity

7.Good creep resistance

Application of the Acid refractory silica bricks

The refractory silica bricks are primarily used for furnaces and kilns in the field of metallurgy, steel, power, chemical industry, and electric power and machine building etc.

Physical & chemical indexes of the Acid refractory silica bricks

Item | Unit | BGZ-65 |

SiO2 | % | ≥65 |

Al2O3 | % | ≤30 |

K2O+Na2O | % | ≤1.0 |

Permanent linear Change(1350°C×2h) | % | ±0.2 |

Apparent porosity | % | ≤24 |

Cold crushing strength | Mpa | ≥25 |

Refractoriness under load, 0.2MPa | °C | ≥1350 |

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick products according to the standard JC/T615-1996, the single brick is divided into 3 grades: XBG-96, ZBG-96, DBG-96.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- The scale quartz is a spear shaped double crystal structure, very compact and favorable to the increase of thermal conductivity. The high thermal conductivity of silica brick in improving thermal conductivity and other performance indicators and traditional coke silicabrick agreement.That is to say, the high thermal conductivity of silica brick all inherited the traditional advantages of coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

Send your message to us

Silica Brick - Refractory Acid Resistance for Furnace Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords