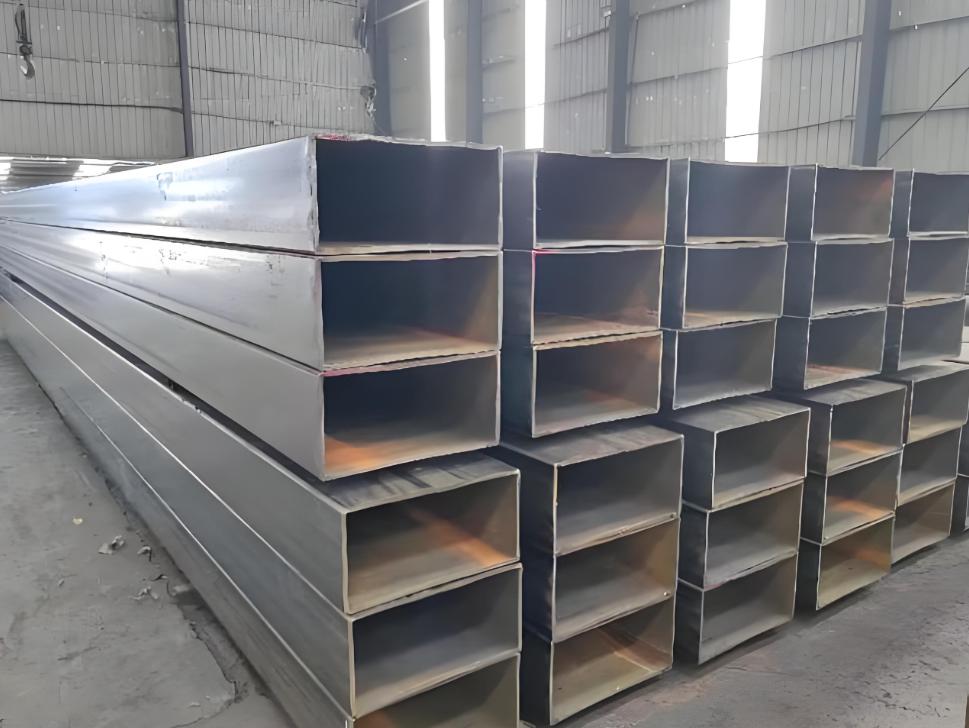

SHS RHS CHS square hollow section rectangular hollow section circular hollow section pipe & tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

GB

Technique:

Cold Rolled,Cold Drawn,ERW,Extruded,Hot Rolled

Shape:

Square,Round,Rectangular,Oval

Surface Treatment:

Galvanized,Black

Steel Grade:

Q195,Q235,Q355

Thickness:

0.15-20mm

Length:

1-12m or customized

Net Weight:

0.625-171.658kg/m

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact rcjs steel.

| Type | cold rolled pre-galvanized welded square/rectangular steel pipe/tube/hollow section prefab house steel pipe |

| Diameter | 10mm-600mm or as customized |

| Wall Thickness | 0.1mm-300mm or as required |

| Length | 2-12m or as request |

| Standard | ASTM A53, BS 1387, BS 1139, BS En10025, etc. |

| Steel Grade | Q195 = S195 / A53 Grade AQ235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2Q345 = S355JR / A500 Grade B Grade C |

| Surface Treatment | Bared, Black Painted, Galvanized, Oiled or to your requirements |

| Technique | Welded |

| Package | Packed in Bundles with Two Nylon Strip. |

| Application | 1. Fluid pipe 2. Power Plant 3. Structure pipe 4. High and low-pressure Boiler tube 5. Seamless pipe /tube for petroleum cracking 6. Conduit pipe 7. Scaffolding pipe pharmaceutical andship, building etc. |

| Advantages | Competitive price, High-quality products, 24-hour after-sales service |

| Port | Tianjin |

| Currency | USD, CNY, etc. |

| Payment | T/T, L/C, D/P, etc |

- Q: How to perform nondestructive inspection of steel tubes

- The detection principle is based on the ferromagnetic material is magnetized in a magnetic field, discontinuity materials and products (defects) produce leakage magnetic field, magnetic powder adsorption (or detecting) and appear (or on the instrument display). Therefore, this method can only be used for the inspection of the surface or near surface defects of ferromagnetic materials or products.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel pipes are known for their strength and durability, making them suitable for various applications. They are capable of withstanding high pressures without deformation or leakage, while also being reliable for low-pressure systems.

- Q: How are steel pipes used in the automotive industry?

- Steel pipes are commonly used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and resistance to high temperatures, making them ideal for carrying exhaust gases, fuel, and providing support to the vehicle's frame.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes. They are commonly used to create the foundation structures, such as monopiles and jacket structures, which provide stability and support for the turbines in the seabed. Steel pipes are also utilized for the construction of the tower and nacelle structures, providing a strong and durable framework for the turbine components. Additionally, steel pipes are employed for the installation of subsea cables, allowing for the transmission of electricity generated by the turbines to the shore. Overall, steel pipes play a crucial role in the manufacturing of offshore wind turbines by providing the necessary strength, stability, and infrastructure required for their operation.

- Q: What is the average lifespan of steel pipes?

- The average lifespan of steel pipes varies depending on various factors such as their quality, usage, and maintenance. However, under normal conditions, well-maintained steel pipes can last for several decades or even longer.

- Q: What is the purpose of pipe flanges in steel pipes?

- The purpose of pipe flanges in steel pipes is to provide a connection point between two pipe sections, allowing for easy assembly, disassembly, and maintenance of the pipeline. Flanges also help to create a leak-proof seal, enhance the strength and stability of the joint, and provide flexibility for expansion and contraction of the pipes.

- Q: Are steel pipes suitable for wastewater treatment plants?

- Yes, steel pipes are suitable for wastewater treatment plants. Steel pipes are known for their durability, corrosion resistance, and high strength, making them ideal for handling the demanding conditions of wastewater treatment plants. They can effectively transport and contain wastewater without any structural or functional issues, ensuring efficient and reliable operation of the treatment process.

- Q: How do steel pipes handle soil movement?

- Steel pipes are able to handle soil movement quite well due to their inherent strength and durability. The rigid nature of steel pipes allows them to withstand ground shifting, settling, and other soil movements without significant deformation or damage. Additionally, steel pipes can be reinforced with additional supports and anchoring systems to further enhance their ability to handle soil movement.

- Q: Can steel pipes be used for compressed air systems?

- Yes, steel pipes can be used for compressed air systems. Steel pipes are commonly used for their strength and durability, making them suitable for handling the high pressures involved in compressed air systems. However, it is important to ensure that the steel pipes are specifically designed and rated for compressed air applications to ensure safety and prevent any potential leaks or failures.

- Q: How can seamless steel tubes be produced?

- The material of rolling seamless tube is round tube blank, and the billet is processed by cutting machine to grow about 1 meters, and sent to the furnace by conveyor belt. The billets are heated into a furnace and the temperature is about 1200 degrees celsius. The fuel is hydrogen or acetylene. The temperature control in the furnace is a key problem. When the round billet is released, it should be punched through the pressure piercer. The most common punching machine is a cone roll piercer, which has high production efficiency, good product quality, large perforation and expanding diameter, and can be used in various steel grades. After the perforation, the round tube blank has been successively rolled, rolled or squeezed by three rollers.

Send your message to us

SHS RHS CHS square hollow section rectangular hollow section circular hollow section pipe & tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords