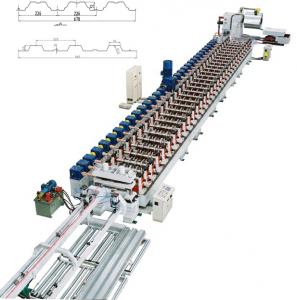

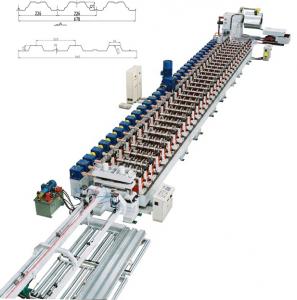

Polyurethane composite plate production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Is the production of a large number of polyurethane composite boardproduction line equipment, the so-called production line is a set of production equipment, has a complete process. To understand the "polyurethanecomposite board production line" we must first make clear what is polyurethane composite board.

Polyurethane composite board is also called PU sandwich board. Polyurethanecomposite board core material from the upper and lower color steel plate with a middle foamed polyurethane composition, with six components online worldadvanced automatic operation of mixed casting technology, mixing processcan be completed online disposable society ingredients center or the factory,and can be freely adjusted according to the temperature online, so as to produce building sheet out of the ordinary high strength, energy saving, green environmental protection.

Mainly applies to: polyurethane composite building board

Polyurethane composite plate production line type: Mark/L

Size: 1.6x12.2 M

Pressure: 2kg/cm2

The highest temperature of 120 DEG C:

As the vast number of users in the purchase of polyurethane composite plate production line must consider the production line can improve the workefficiency and save cost and produce high quality sheet. Polyurethanecomposite plate production line good these few indispensable; Shanghai DingDi CNC equipment as Italy meaning a Prius in Chinese general agent, mainlyselling all kinds of hydraulic machine and production line. Tailored to the userpresses and production line.

Multifunctional steel heat insulation composite board production line is introduced:

HYF production line adopts advanced production technology to gas, electric,machinery as a whole, is a special equipment for processing steel heat insulation composite board, working speed by frequency conversion stepless speed regulation, can one-time composite tile Leng composite plate, a full set of production line discharge pressure type mechanism, (rib pressing, glue,heating, composite, curling, slotted, trimming, pneumatic, automatic cutting)composition, is the production of industrial workshop, warehouse roof paneland wall indispensable equipment.

Technical parameters:

Power supply 380V/50-60HZ;

Total power: 32kw;

The production line speed: 1000mm, 1200mm;

Thickness: 50-250mm;

Annual production: 600000 square meters;

Polystyrene sandwich plate is composed of a color to do surface, self extinguishing closed cell polystyrene foam as the core material, the colorpressure plate through the automated continuous molding machine after usingpolyurethane (A, B) is formed by bonding an efficient new composite materials,mainly applied in public buildings, industrial factory building roof, walls andclean the building and the combination of cold storage, floor of building, kiosks and other, it has the thermal insulation, waterproof finish in one time, high construction speed, durable, beautiful appearance and other characteristics.

Rock wool sandwich panel series

Color rockwool sandwich panel is the core materials with rupture of fibrousmineral wool, with color steel plate to do surface, through the automated continuous molding machine, press type with high strength adhesive bonding.Because the color steel plate and sandwich rockwool are non combustible, so its excellent fireproof performance. Suitable for the use of roof, wall panel.

Rock wool sandwich panel series

Polyurethane sandwich plate is a sheet metal color coating steel plate to choose two house of high quality or other precision pressure as the surface material, intermediate injection flame retardant polyurethane foam liquid,through the high pressure foaming and curing and so on certain conditions,and the metal panel strongly agglutinated appearance, flat, steel toughconstruction plate. Have fire prevention, waterproof, heat insulation, noise characteristics. Bring high-quality appearance effect to the building energy saving, is currently the world's most forward-looking insulation, green environmental protection building plate

Polyurethane sandwich panel series

Glass wool sandwich panel is upper and lower two layers of color steel platethrough the keel and glass cotton combination, divided into the roof panel and wall plate two class. Net hanging type glass wool sandwich plate is a new type of insulation roofing material for stainless steel wire instead of lower color pressure plate. Glass cotton sandwich plate can be all kinds of plate pressingplate. Has the good fireproof performance, is suitable for large-scale public buildings, industrial buildings and other construction of the walls and roof.

- Q: What is the roll forming machine?

- The mold base elliptical motion device comprises a mold base, a slider, a slider block, a mold plate, a fixing plate, an elliptical long shaft adjusting rod and a mold base, wherein the mold base is connected with the slider through the lower part,

- Q: How is the molding machine installed?

- 1 check the machine in the transport process is damaged or deformation;

- Q: How to maintain the molding machine?

- 5 After the end of the work every day, the various parts of the machine should be in the initial state and thoroughly clean the various parts of the machinery to prevent concrete in the mechanical condensation, but not water washing machine;

Send your message to us

Polyurethane composite plate production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords