SG series Dry Granulating machine - granulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

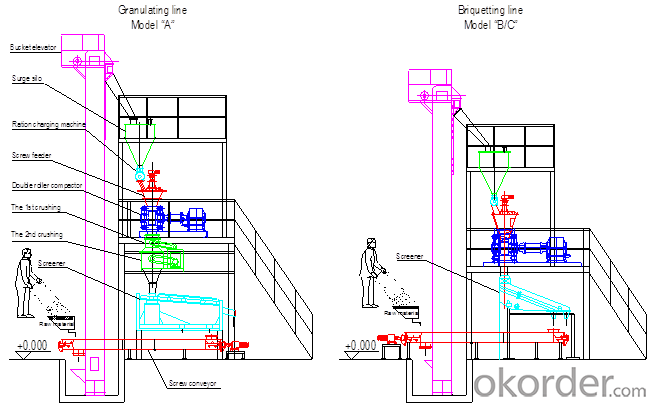

1、Structure of SG series Dry Granulating machine

SG series Dry Granulating machine consist of various types of granulation equipments based on the dry method while the basic principle is the same. The dry powder material from the top to join, by deaeration, spiral preload to enter the gap between the rollers, the rollers of great pressure cause the material plastic deformation is compacted into a sheet. The sheet material is then crushed and screened to get the final granular products. The compacting pressure can be adjusted by the hydraulic cylinders according to the requirements of the granulation operation. Different pressure settings can get granular products of different strength.

2Main Features of the SG series Dry Granulating machine

•The material is compacted into granules/briquettes through mechanical pressure, without adding any wet agent. The product purity is guaranteed.

•The process flow has shorter and lower in power consumption as well as less accessory equipment and worker.

•The dry powder can be granulated directly. No need of further drying.

•Higher granule strength. Bulk specific gravity improvement is more obvious than other granulation methods.

•More flexibility in operation. Wide application. The size of granule/briquettes strength can be adjusted through hydraulic pressure.

•The system is closed loop operation realizing the continuous production

3 The SG series Dry Granulating machine Finished products imagine

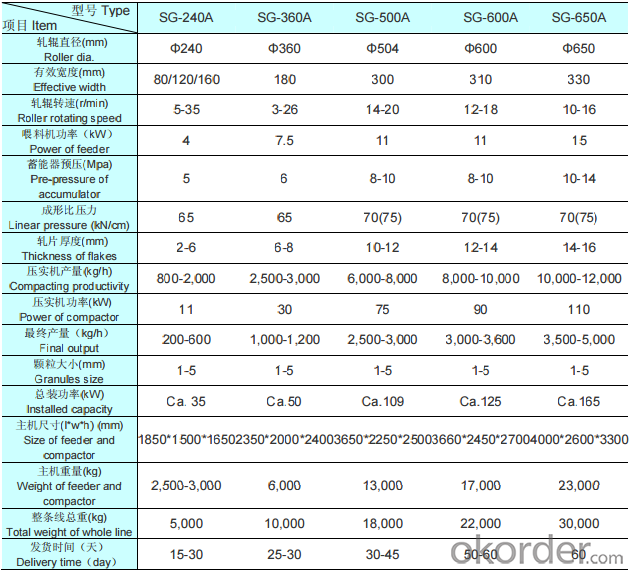

4 The SG series Dry Granulating machine Specification

5.FAQ

①How to guarantee the quality of the products?

Any product delivered by our company, we will designate the technical to install and adjust, provide the best service for the customers. We will also provide necessary follow-up service assurance. Since the customer checks and accepts the equipment, the equipment is guaranteed for one year and maintained for the whole life.

- Q: What is the chemical equipment

- In the chemical production in order to raw materials processed into certain specifications of the finished product, often takes raw material pretreatment, chemical reaction and separation of reaction products and refined a series of chemical process, implement these processes used in machinery, are often classified as chemical equipment

- Q: Why is the volume of the chemical plant bulky

- Refers to contain management personnel, technical personnel, the people, these people is the software factory strength, their work can let the factory work, produce benefit; Planning "work", is to do well the recruitment and training of the person, assure the software strength development of the factory.

- Q: What is the electrical equipment of the chemical plant? How do you solve the lubrication problem

- The equipment and equipment used shall conform to the state's current technical standards (including national and local standards). There are... According to a chemical plant, the accident statistics show that the accident occurred in the electrical equipment junction box. Lubrication is the important content of tribology research. Improving the friction state of friction to reduce friction resistance to reduce wear and tear technology. Lubricated by lubricants. In addition, lubricants also have anti-rust, damping, sealing, transmission power and so on. The use of modern lubrication technology can significantly improve the performance and longevity of the machine and reduce energy consumption.

- Q: In a chemical industry, the electrician's department is cutting away from where it is made. Is that ok

- Explosion accident prone to chemical enterprises in the production of raw materials and products are flammable and explosive, the characteristic of high temperature and high pressure, prone to leakage of chemical dangerous goods when maintenance or remaining in the equipment lines, in the commissioning phase may be remaining in the equipment or mixed with air, form an explosive mixture gas, once fires raging fires often and severe losses.

- Q: The chemical plant is used mechanically

- This problem is very large, mainly looking at the main products of the chemical works For example, urea production plant, the main equipment is stripper, high pressure condenser, high pressure scrubber, urine tower, etc In the case of pharmaceutical factories, there are mainly fermentation equipment, synthetic equipment, filtration equipment, drying equipment, separation equipment, water equipment, sewage treatment equipment and so on There are some things there are a lot of chemical plant, such as the most basic pumps, tanks, reaction vessel (reaction vessel according to the different factory there are many), air separation equipment (the) most chemical plant, etc I hope the answer will help you

- Q: I want to do a professional job, which department is suitable for me? My company mainly does chemical equipment, it is machinery factory.

- Do the craft, do the equipment Lab technician that is OK

- Q: There are chemical products for machining

- Popular said, mechanical processing is according to the drawings design requires the use of machinery and equipment. Through forging cutting. Extrusion method changes the shape of the blank workpiece. Such as size, surface quality, etc. The machine of forging, cutting, milling, planing, grinding, etc. Common or numerical control machine tools, and the specialized machine tools for processing large quantities of products.

- Q: Is the pipe thread and tubing buckle the same thread in petrochemical machinery?

- I don't think it's the same thing, the pipe thread is a thread, but the buckle is a quick connector.

- Q: The overall requirements of the products for the fans are higher

- Gas recovery unit, dust removal device, exhaust device, etc.

- Q: What can be used for titanium or titanium alloy materials in the chemical industry?

- The application of titanium in the chemical industry: Because the titanium has excellent corrosion resistance, mechanical properties and process performance, many departments are widely used to national economy. Especially in the chemical production, using titanium instead of stainless steel, nickel base alloy and other precious metals as a corrosion resistant materials. This to increase production, improve product quality, prolong the service life of equipment, reduce consumption, reduce the energy consumption and reduce costs, to prevent pollution, improve working conditions and improve labor productivity and so on has the very vital significance. Titanium has become one of the main anti-corrosion materials in chemical equipment, and in the chemical plant has established his corrosion status. As the ideal material in chemical equipment, titanium will become more and more cause the attention of engineering and technical personnel.

Send your message to us

SG series Dry Granulating machine - granulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords