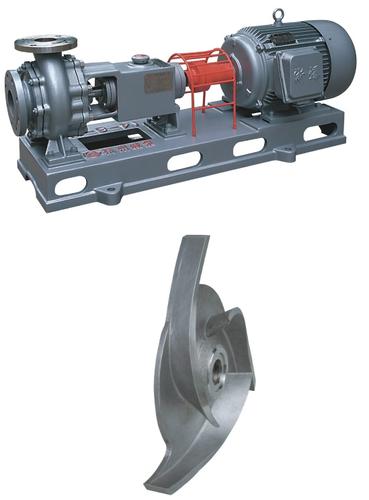

Pump impeller

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal centrifugal pump

Complies to API610, 682,ISO2858standards

Max pressure: 2.5MPa

Capacity: 0.64~2400 m3/h

Head: 4~250m

Model: IJ series chemical processpump: Horizontal single stage pump

Capacity : 0.64-2400m3/h

T: -20---200oC

Material (For wet parts in contactwith medium): CS, cast iron, 304(0Cr18Ni99ti), 305 (1cr18ni9t), MCU, CD4MCu,316, 316L, 310S, alloy 20#, 904, ta2, Ti/pd (titanium-palladium alloy), Ni(nickel), Monel. Dual-phase stainless steel, etc.

These materials have been selectedas a result of many years of experience in the use of chemical engineeringmaterial, to satisfy the special demands made in pump construction.

Mechanical seal: According tocustomer's requirements

We provide:

1. Mechanical seal---171(A) mechanicalseal (this kind of seal is the national-patented product, patent No. ZL92 220977.4 ) single or dual MS.

2. Dynamic seal.

3. Packing gland seal.

Or other brands.

Coupling: Pin type coupling

Usage:

Soda, paper, salts. Metallurgy,acid-making, petrochemical, fiber, plastic, paper-making, chemical fertilizer.Fermentation, environmental protection.

Please. Visit our web site to getmore information of this

- Q: What is the chemical equipment

- In the chemical production in order to raw materials processed into certain specifications of the finished product, often takes raw material pretreatment, chemical reaction and separation of reaction products and refined a series of chemical process, implement these processes used in machinery, are often classified as chemical equipment

- Q: What kind of production equipment do petrochemical industry use,

- Mixer, compressor, pipe, heat exchanger, air cooling, towerReaction kettle, rectification tower, heat exchanger...

- Q: What are the characteristics of chemical equipment

- What are the characteristics of chemical equipment Chemical production unit is made of a complete set of chemical equipment, chemical machinery, and other such as chemical instrumentation, chemical piping and valves, etc, to ensure the safety of the whole device is stable and reliable production,

- Q: How to enter oneself for an examination?

- Qualification examination requirement of registered chemical engineer The basic examination of registered chemical engineers shall meet one of the following conditions: An undergraduate or above degree in this major or similar professional university. The article is a professional or similar specialized college degree, and has been engaged in chemical engineering design for one year. Bachelor degree or above, bachelor degree or above in other engineering major, I have been engaged in chemical engineering design for one year.

- Q: Which equipment should be classified into the main equipment in chemical production?

- If the device has a problem, it will affect the device's manufacturing or safety equipment.

- Q: Production equipment and system sealing operation in chemical production

- The production of combustible material is much, the variety is much. Chemical industry production process, in order to guarantee the normal production, continuous and stable manner, need according to the requirement of the production scale, to store a certain amount of raw materials, intermediate products and finished products. The larger the device's size, the more storage it has. And the raw materials, intermediate products and finished products of fine chemicals are more flammable liquids and solids. The principle of basic fire prevention is that the more fuel you produce and store, the greater the risk of fire. Moreover, there are more common varieties in the production process of fine chemical enterprises, which makes management a certain difficulty.

- Q: I want to do a professional job, which department is suitable for me? My company mainly does chemical equipment, it is machinery factory.

- Do the craft, do the equipment Lab technician that is OK

- Q: What is the chemical machinery

- Chemical machinery, the general term for machinery and equipment used in the production of chemical industry. In the chemical production in order to raw materials processed into certain specifications of the finished product, often takes raw material pretreatment, chemical reaction and separation of reaction products and refined a series of chemical process, implement these processes used in machinery, are often classified as chemical machinery.

- Q: What kind of packing bags do you need?

- I do plastic wrap, but I don't know what you want to know.

- Q: What is the production and attention of water treatment in chemical industry?

- Ultrapure water is the state environmental protection requirements which conform to the national first class or second class discharge standard of water, water purifier used in the process of water treatment poly aluminium or polyacrylamide remember not to pay attention to the usage form secondary pollution

Send your message to us

Pump impeller

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords