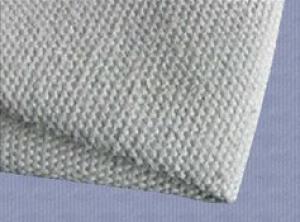

Seal Ceramic Glass Fiber Textile Fiber Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Twisted Rope | Application: | Heat Insulation | Thickness: | 4-60mm |

| Width: | 4-60mm | Length: | 30m | Grade: | HA (High Aluminum) |

| Chemical Composition: | AL2O3+SIO2 | Ultimate Strength (≥ MPa): | 0.04 | Working Temperature: | 1260 |

| Fiber Diameter: | 2-5um | Thermal Conductivity: | 0.075-0.175 w/m.k | Shrinkage (1800℉, 3h): | <=-3 |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | ceramic textile fiber rope | |

| Color: | White | fire-resistant rope density: | 600-620kg/m3 | ceramic rope: | ceramic rope braided |

| fire resistant rope: | ceramic textile fiber rope |

Packaging & Delivery

| Packaging Detail: | ceramic textile fiber rope package: carton with inner plastic bag |

| Delivery Detail: | 15days after receiving advance payment |

Production description of ceramic textile fiber rope

Iterm | Ceramic fiber ceramic rope twisted |

Type | Ceramic fiber ceramic rope twisted |

Ceramic fiber ceramic rope twisted | |

Ceramic fiber ceramic rope twisted | |

Characteristics | ** Good thermal insulation |

** Excellent high temperature strength | |

** Good electrical insulation properties | |

** High chemical stability | |

** Low thermal conductivity | |

Typical Use | Hightemperature pipe insulation and seal,cable insulation coating, flexible expansion joint connection,coke oven opening seal |

MOQ | 30m |

FOB Price | 4-6.5 USD/KG |

Port | Qingdao |

Payment Terms | L/C, D/A, D/P, T/T |

Packing | Carton with inner plastic bags |

Delivery | Within 15 days after delivery deposit |

Certificate | ISO9001, MSDS |

Product details of ceramic textile fiber rope

Type | Ref.No. | Reinforcement | Work. Temp (°C) | Density (kg/m3) | Size (mm) |

Twisted Rope | C101TG | Glass filament | 1260 | 600-620 | 6-40 |

C101TS | Stainless steel wire | 1260 | 600-620 | 6-40 | |

Round Braided Rope | C101TG | Glass filament | 1260 | 600-620 | 6-160 |

C101TS | Stainless steel wire | 1260 | 600-620 | 6-160 |

- Q: Can glass fiber textiles be used in air ducts?

- Indeed, air ducts can make use of glass fiber textiles. These textiles are often employed as insulation materials in HVAC systems, which encompass air ducts. They possess outstanding thermal qualities that offer insulation, thereby preventing heat transfer and preserving the desired temperature within the ducts. Additionally, glass fiber textiles possess resistance against moisture, mold, and mildew, rendering them highly suitable for deployment in environments characterized by elevated humidity levels. Furthermore, due to their lightweight nature and ease of installation, they present a practical choice for air ducts. Taken as a whole, glass fiber textiles represent a fitting option for insulating and safeguarding air ducts across various HVAC applications.

- Q: How do glass fiber textiles absorb or repel moisture?

- Glass fiber textiles possess hydrophobic properties as they repel moisture. This is due to the non-porous nature of glass, preventing water absorption. The smooth surface of glass fibers lacks open spaces or pores for water molecules to enter. Consequently, when water contacts glass fiber textiles, it forms droplets that easily slide off the surface without absorption. Moreover, glass fiber textiles can undergo treatment with specialized coatings to enhance their hydrophobic characteristics. These coatings generate a thin layer on the fiber surface, further reducing moisture absorption. The coating molecules act as a barrier, repelling water and causing it to form droplets that roll off the fabric. It's important to note that although glass fiber textiles repel moisture, they are not entirely waterproof. Excessive water exposure or high pressure can enable water to penetrate the fabric through the gaps between the fibers. However, when compared to other natural or synthetic fibers, glass fiber textiles exhibit exceptional resistance to water absorption and can retain their properties even in wet conditions.

- Q: Can glass fiber textiles be used in the production of protective gloves?

- Yes, glass fiber textiles can be used in the production of protective gloves. Glass fiber textiles are known for their high strength and heat resistance properties, making them suitable for applications where protection from cuts, abrasions, and heat is required.

- Q: How do glass fiber textiles contribute to flame resistance?

- Glass fiber textiles contribute to flame resistance in several ways. Firstly, glass fibers have a high melting point, typically around 1500 degrees Celsius, which means that they are less likely to ignite or burn compared to other textile materials such as natural fibers or synthetic materials like polyester or nylon. This high melting point makes glass fiber textiles inherently flame resistant. Secondly, the structure of glass fibers provides a barrier to the spread of flames. The fibers are tightly woven together, creating a dense fabric that is difficult for flames to penetrate. This prevents the fire from spreading and consuming the textile material. Furthermore, glass fiber textiles do not produce flammable gases when exposed to flames. Unlike some synthetic materials which release toxic fumes and gases when burned, glass fibers remain relatively inert and do not contribute to the spread of fire. In addition, glass fiber textiles have a low thermal conductivity, meaning they do not conduct heat efficiently. This property helps to reduce the transfer of heat from the flame to the fabric, minimizing the risk of ignition. Lastly, glass fiber textiles can be treated with flame retardant chemicals to enhance their flame resistance properties. These chemicals can be applied during the manufacturing process or as a post-treatment, further improving the fabric's resistance to flames and reducing the risk of ignition. Overall, the combination of the inherent properties of glass fibers and the ability to be treated with flame retardants make glass fiber textiles highly effective in contributing to flame resistance.

- Q: How do glass fiber textiles affect the drapability of fabrics?

- Glass fiber textiles, also known as fiberglass textiles, can significantly affect the drapability of fabrics. The addition of glass fibers to a fabric can enhance its stiffness and rigidity, making it less likely to drape naturally. This is because glass fibers have a high tensile strength and are relatively inflexible compared to natural or synthetic fibers commonly used in textiles. When glass fiber textiles are incorporated into fabrics, they create a network of interlocking fibers that add structure and stability to the material. This can be desirable in certain applications where a more rigid fabric is desired, such as in industrial or technical textiles. However, in garments or home furnishings where drape and fluidity are important, the presence of glass fibers can be a disadvantage. The stiffness imparted by glass fiber textiles can restrict the movement and flow of the fabric, leading to a less natural drape. Fabrics with glass fibers may not hang as smoothly or gracefully as those without, and may appear more stiff and rigid when worn or used in drapery. Additionally, the presence of glass fibers can affect the feel and texture of the fabric, making it potentially less comfortable against the skin. It is worth noting that the extent to which glass fiber textiles affect drapability can vary depending on the concentration and distribution of the fibers within the fabric. Higher concentrations of glass fibers or a more densely woven or knitted structure will generally result in a more pronounced impact on drapability. Overall, while glass fiber textiles can offer certain benefits in terms of strength and stability, they can have a negative impact on the drapability of fabrics. It is important for designers and manufacturers to consider the intended application and desired characteristics of a fabric when deciding whether to incorporate glass fibers or opt for other alternatives.

- Q: Can glass fiber textile be used in artificial turf?

- Artificial turf can indeed utilize glass fiber textile. Renowned for its robustness and ability to withstand harsh weather conditions, moisture, and UV rays, glass fiber is an ideal material. Consequently, it is well-suited for application in artificial turf, which frequently encounters outdoor elements. By reinforcing the turf, the glass fiber textile enhances its stability and lifespan. Moreover, this lightweight material is effortless to install and maintain. Its impermeable nature also prevents the accumulation of dirt, dust, and bacteria, ensuring a pristine and sanitary playing surface. Overall, incorporating glass fiber textile into artificial turf can enhance its performance, durability, and visual appeal.

- Q: How do glass fiber textiles affect the flexibility or stiffness of fabrics?

- Glass fiber textiles can significantly impact the flexibility or stiffness of fabrics. When incorporated into fabrics, glass fibers add strength and rigidity, making the fabric stiffer and less flexible. This is particularly useful in applications where structural support is required, such as in reinforced composites or industrial fabrics. However, the extent of the effect on flexibility or stiffness depends on the concentration and arrangement of glass fibers within the fabric.

- Q: What are the different additives used in glass fiber textiles?

- There are several additives that are commonly used in glass fiber textiles to enhance their performance and functionality. These additives can be classified into various categories based on their intended purpose. One category of additives used in glass fiber textiles is sizing agents. Sizing agents are applied to the glass fibers during the manufacturing process to improve their handling characteristics and adhesion to other materials. They also help to reduce static electricity and improve the wetting properties of the fibers, ensuring better impregnation of resins or other binding materials. Another category of additives is flame retardants. Flame retardants are added to glass fiber textiles to enhance their resistance to fire and reduce the risk of ignition and spread of flames. These additives can help to improve the safety of the textiles in various applications, such as in building materials, automotive interiors, and protective clothing. UV stabilizers are also commonly used additives in glass fiber textiles. These additives help to protect the textiles from degradation caused by exposure to ultraviolet (UV) radiation from the sun. UV stabilizers can extend the lifespan of the textiles and maintain their color and physical properties, making them suitable for outdoor applications. Antistatic agents are additives used to reduce or eliminate static electricity in glass fiber textiles. Static electricity can cause various issues, such as attracting dust and dirt, interfering with electronic equipment, and posing a risk of electrostatic discharge. Antistatic agents help to dissipate static charges and improve the conductivity of the textiles, ensuring a static-free environment. Furthermore, lubricants can be used as additives in glass fiber textiles to improve their processing and handling properties. These lubricants can reduce friction and facilitate the movement of fibers during the weaving or knitting process, making it easier to produce high-quality textiles. It is worth mentioning that the specific additives used in glass fiber textiles can vary depending on the intended application and the desired properties of the final product. Manufacturers carefully select the appropriate additives to meet the specific requirements and performance standards of different industries and applications.

- Q: Can glass fiber textiles be used as reinforcement in composites?

- Yes, glass fiber textiles can be used as reinforcement in composites. Glass fibers are known for their high strength and stiffness, making them a popular choice for reinforcing materials such as polymers and resins. The textiles can be woven or non-woven and are commonly used in industries like aerospace, automotive, and construction for enhancing the mechanical properties of composite materials.

- Q: How does glass fiber textile compare to other types of textiles?

- Glass fiber textiles, also known as fiberglass textiles, have several unique properties that set them apart from other types of textiles. Firstly, glass fiber textiles offer exceptional strength and durability. The fibers themselves are made from molten glass that is spun into thin strands, resulting in a textile that is incredibly strong and resistant to wear and tear. This makes glass fiber textiles ideal for applications that require high tensile strength, such as reinforcement in composite materials or protective clothing. In addition to their strength, glass fiber textiles also have excellent heat and chemical resistance. Glass fibers have a high melting point, which enables them to withstand extreme temperatures without degrading or losing their structural integrity. This makes them suitable for use in industrial settings, where exposure to heat and corrosive chemicals is common. Another advantage of glass fiber textiles is their low electrical conductivity. Glass is an insulator, meaning it does not readily conduct electricity. This property makes glass fiber textiles ideal for applications in electrical and electronics industries, where materials with low conductivity are required to avoid interference or damage to sensitive equipment. Furthermore, glass fiber textiles are lightweight and flexible, allowing for ease of handling and installation in various applications. They can be woven or knitted into different patterns and thicknesses, providing versatility in meeting specific design requirements. However, it is worth noting that glass fiber textiles also have some limitations. They can be relatively brittle compared to other textiles, and repeated flexing or bending may cause them to break. Additionally, glass fibers can be irritating to the skin and respiratory system if not properly handled, requiring appropriate safety precautions during manufacturing and installation. Overall, glass fiber textiles offer unique properties such as high strength, heat and chemical resistance, low electrical conductivity, and versatility in design. These characteristics make them a preferred choice for a wide range of applications, especially in industries where strength, durability, and resistance to extreme conditions are crucial.

Send your message to us

Seal Ceramic Glass Fiber Textile Fiber Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords