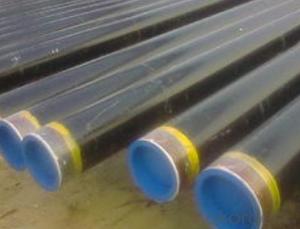

Schedule 40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335P5 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 2.0 - 85 mm | Section Shape: | Round | Outer Diameter: | 17 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Oil Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | VARNISH PAITING |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | END: | PLAIN,BEVELED OR THREADED |

| Grade: | 10#,20#,16Mn,A106(B,C),A210,A335 P5,A335 P91,A53(A,B),API J55,API K55,Q195,Q235,Q345,St37,St52,10#-45#,A53-A369,API J55-API P110,Q195-Q345,ST35-ST52 | Standard: | API 5CT,API 5L,ASME B36.19M-2004,ASTM A106-2006,ASTM A179-1990,ASTM A182-2001,ASTM A53-2007,BS 1387,DIN 1629/3,DIN EN 10216-1-2004,GB 5310-1995,GB/T 3091-2001,GB/T 8162-1999,GB/T 8163-1999,JIS G3454-2007,API,ASTM,BS,DIN,GB,JIS |

Packaging & Delivery

| Packaging Detail: | standard packing suitable shipping by sea.fixed length as customers' requirements, or SRL or DRL. Varnish, painting or galvanized, or FBE ,2PE,3PE 3pp coating,bevelled/plain/threaded ends with caps, packing in bundle (OD smaller than 141.3mm) big sizes packing in loose, marking as required. Shipped by sea,by air,by train . or some samples shipped by DHL,EMS,TNT,FEDEX ect. Length shorter than 5.85m should be shipped by 20' container, 5.85-12m shipped by 40' container. |

| Delivery Detail: | 7-35 days after advance payment |

Product Description

Seamless steel pipes, a large number of used pipes conveying fluids, such as transport oil, natural gas, gas, water pipes and some solid materials, and so on. Compared to other steel and solid steel bar, the same torsional strength in bending, lighter, is an economic cross-section steel, widely used in the manufacture of structural parts and mechanical parts, such as drill pipe, automotive drive shafts, bicycle rack and construction using steel scaffolding ring with steel pipe manufacturing parts, can improve material utilization, simplify the manufacturing process, saving material and machining time, such as bearing rings, jack sets, has been widely used to manufacture steel. Steel or a variety of conventional weapons indispensable material, gun barrels to make steel. Steel shapes in different cross-sectional area can be divided into tube and shaped tubes. As in the perimeter of equal conditions, the largest area of a circle with a circular tube can carry more fluid. In addition, the circular cross section to withstand internal or external radial pressure, the force is uniform, so the vast majority of the pipe is pipe.

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development for various purposes. They are commonly used for transporting water, oil, and gas, as well as for drainage systems and sewage networks. Steel pipes are also used in the construction of bridges, buildings, and highways, providing structural support and stability. Additionally, steel pipes are utilized in underground utilities, such as telecommunications and electrical systems. Their durability, strength, and resistance to corrosion make steel pipes a crucial component in infrastructure development.

- Q: How are steel pipes used in the construction of pipelines?

- Steel pipes are commonly used in the construction of pipelines due to their high durability, strength, and ability to withstand high pressure. These pipes are used to transport various fluids, such as oil, gas, and water, over long distances. They are welded together and laid underground or submerged to create a reliable and efficient transportation system for these resources.

- Q: What are the different end types for steel pipes?

- Steel pipes can have various end types, each designed for a specific purpose. Some common end types include: 1. Plain End: This is the simplest type, with no threading or special treatment. It is used for non-threaded applications or when welding is required. 2. Threaded End: These ends have male threads on one or both sides, allowing for easy connection with other threaded fittings or pipes. They are commonly used in plumbing and gas applications that require easy assembly and disassembly. 3. Beveled End: Beveled ends are cut at an angle (usually 30 or 45 degrees) to facilitate welding. The smooth transition between the pipe and the weld joint ensures a strong connection. They are used in construction, oil and gas, and pipeline industries. 4. Coupling End: These ends have female threads on both sides, enabling the joining of two pipes with a coupling or fitting. They are often used in plumbing systems or for easily disassembling pipe sections. 5. Flanged End: Flanged ends have a flared or raised lip on one or both sides, allowing for easy attachment to other flanged components like valves or pumps. They are commonly used in industrial applications requiring secure connections. 6. Socket Weld End: These ends have a socket or recess on one or both sides, allowing for easy connection with socket weld fittings. They provide a strong joint and are commonly used in high-pressure applications, such as petrochemical or power plants. These examples demonstrate the variety of end types available for steel pipes. The choice depends on specific application requirements, including the need for easy assembly, disassembly, or compatibility with other fittings.

- Q: How are steel pipes connected together?

- Steel pipes are typically connected together using various methods such as welding, threading, or using mechanical fittings, depending on the specific application and requirements.

- Q: Difference between cold rolled steel pipe and common steel pipe

- 1, from the dimension accuracy above, cold-rolled steel pipe size is good, high precision2. from the outward appearance, the surface of cold-rolled steel pipe is bright, and the surface of hot rolled steel pipe has obvious oxide skin or red rust

- Q: How are steel pipes used in industrial manufacturing processes?

- Steel pipes are commonly used in industrial manufacturing processes for various purposes such as transporting fluids, gases, and solids, providing structural support, and facilitating heat transfer. They are used in industries like oil and gas, construction, automotive, and manufacturing, where they are utilized for plumbing systems, conveyance of materials, and as a durable and reliable medium for handling high-pressure and high-temperature applications.

- Q: What are the applications of steel pipes in the automotive industry?

- Steel pipes are used in the automotive industry for a variety of applications, including exhaust systems, fuel lines, and structural components. They provide durability, corrosion resistance, and high strength, making them ideal for withstanding the harsh conditions and heavy loads experienced in automotive applications. Steel pipes also offer flexibility in design and can be tailored to meet specific requirements, ensuring efficient and reliable performance in vehicles.

- Q: How do you calculate the deflection of a steel pipe?

- To calculate the deflection of a steel pipe, you can use the formula for beam deflection, which takes into account the pipe's dimensions, material properties, and applied load. The specific equation you would use depends on the type of loading and support conditions. However, generally, you would need to determine the moment of inertia of the pipe cross-section, the modulus of elasticity of the steel, and the applied load to calculate the deflection.

- Q: What is the difference between steel pipes and fiberglass pipes?

- Steel pipes and fiberglass pipes differ in their material composition and properties. Steel pipes are made of iron and carbon alloy, making them strong and durable. They are suitable for high-pressure applications and can withstand extreme temperatures. In contrast, fiberglass pipes are composed of glass fibers embedded in a resin matrix. They are lightweight, corrosion-resistant, and have excellent thermal insulation properties. Fiberglass pipes are commonly used in industries where corrosion or chemical resistance is required, and they are also more cost-effective for certain applications.

- Q: Is it good to buy a simple wardrobe or a steel pipe?

- If the home place is big, buy Wooden, good-looking durable, if the place is small, buy cloth, easy to receive, mobile, tidy and cheap.

Send your message to us

Schedule 40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335P5 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords