Scaffolding System Ringlock Scaffold Vertical

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Scaffolding System: | Material: | Diameter: | |||

| Surface: | PacKing: |

Packaging & Delivery

| Packaging Detail: | Pallets or As Customer's Requirements |

| Delivery Detail: | 30Days |

Specifications

1.Manufacturer

2.Custom Made: Available

3.Material: Q235 or Q345

4.Surface: Galvanized or Painted

Details

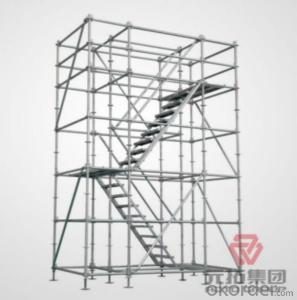

Ring Lock Scaffolding System

OEM service is available

Scaffolding System: Ringlock Scaffolding System

Material: Q235 or Q345

Surface Treatment: Galvanized or Painted or HDG or Powder Coated

Packing: Pallets or As Customer's Requirements

Delivery Time: 30 Days

Auto Welding Machine

A full set of ringlock scaffolding parts offered

Simple and officient to assemble

Specification

| Item Name | Cuplock Scaffolding | |

| Brand Name | Queen | |

| Raw Material | Q235 /Q345steel Grade | |

| Components | Standard.Ledger .Diagonal brace. Top/Bottop Cup/ Ledge Blade | |

| Surface finish | Electric Galvanized/HDG/Powder coated | |

| Size | Pipe size:48.3mm | |

| Thickness:3.25mm | ||

| Usage | Widely used in Bridge .Tunnel.Peterifaction.Shipbuilding .railway,Airport. Dock Industry and Civil Building | |

| Packing | By Steel pallet or bulk | |

- Q: Can steel props be used for temporary support during ductwork installation?

- Yes, steel props can be used for temporary support during ductwork installation. Steel props are adjustable and sturdy, making them ideal for providing temporary support to hold ductwork in place during installation. They can be easily adjusted to the desired height and securely locked into position, ensuring stability and safety for the ductwork. Additionally, steel props are capable of bearing heavy loads, making them suitable for supporting the weight of ductwork and any associated equipment or materials. Overall, steel props offer a reliable and practical solution for temporary support during ductwork installation.

- Q: Can steel props be used for both vertical and horizontal support?

- Yes, steel props can be used for both vertical and horizontal support. Steel props are adjustable metal supports that can be extended or shortened to provide support and stability in construction projects. They are commonly used to support formwork, scaffolding, and temporary structures in both vertical and horizontal orientations.

- Q: How do you ensure proper stability during high wind conditions when using steel props?

- Ensuring proper stability during high wind conditions when using steel props is essential to maintain the safety and integrity of any structure or scaffolding system. Here are some key measures to ensure stability: 1. Evaluate the wind load: Before using steel props, it is crucial to assess the expected wind load on the structure. This can be determined by considering factors such as wind speed, direction, and the dimensions of the structure. Consulting with a structural engineer or referring to relevant codes and standards can provide guidance in this regard. 2. Proper positioning and bracing: Steel props should be placed in strategic positions to provide optimal support and load distribution. The positioning should consider the direction of the wind and the potential for gusts. Additionally, attaching bracing elements such as diagonal struts and tie wires can enhance stability by resisting lateral forces exerted by the wind. 3. Secure base and anchoring: Ensuring a secure base for the steel props is crucial. The props should be placed on a stable and level surface to prevent any shifting or movement. Additionally, anchoring the props to the ground or a fixed structure can greatly enhance stability. Various methods can be employed for anchoring, such as using concrete footing, ground anchors, or attaching the props to a stable structure. 4. Regular inspections: Regular inspections are vital to identify any signs of instability or damage. This includes checking the condition of the props, bracing elements, and anchor points. Any signs of corrosion, deformation, or loosening should be addressed immediately. Inspections should be carried out before and during high wind conditions to ensure ongoing stability. 5. Wind management strategies: Employing wind management strategies can help reduce the impact of high winds. This may involve installing wind screens, deflectors, or creating wind breaks around the structure. These measures can help to disrupt the wind flow and minimize the effect of gusts on the steel props. 6. Continuous monitoring: Monitoring weather conditions and wind speeds is crucial during high wind conditions. Utilizing weather monitoring systems or anemometers can provide real-time data to assess the wind load on the structure. If wind speeds exceed safe limits, appropriate actions such as suspending work or reinforcing the props may be necessary. 7. Compliance with safety regulations: It is essential to adhere to safety regulations and standards related to steel props and scaffolding systems. These regulations often provide guidelines on the use of wind load calculations, proper positioning, bracing, and anchoring methods. By following these measures, it is possible to ensure proper stability during high wind conditions when using steel props, minimizing the risk of structural failure and ensuring the safety of workers and the surrounding environment.

- Q: Set up bearing platform, 9 meters long, width of 4 meters, height of 8.5 meters, the support of the corner of the 4, the length of the direction of the middle of the 4.5 meters (middle), bearing capacity of 150 tons, supporting columns need to choose how much H steel, beams need to choose how much of the H steel, how to calculate?

- Since there are 150 tons of concentrated load in the middle of the bearing platform, in addition to meet the structural strength requirements, but also to meet the structural requirements of grace

- Q: Can steel props be used for supporting temporary bridges during emergencies?

- Yes, steel props can be used for supporting temporary bridges during emergencies. Steel props are strong and durable, making them suitable for providing temporary support to bridges in emergency situations. They can effectively bear the weight and load of the bridge, ensuring its stability and safety until a permanent solution can be implemented.

- Q: Are steel props suitable for use in railway tunnel construction?

- Steel props are indeed suitable for railway tunnel construction. Their strength and durability make them an excellent choice for supporting the tunnel structure during construction. Not only do they provide stability, but they can also withstand the high loads and pressures commonly faced in tunneling projects. Moreover, steel props offer the advantage of adjustability, facilitating effortless installation and removal as construction advances. Due to their versatility and reliability, they are widely favored for railway tunnel construction.

- Q: Steel plate spring material is not only more durable material.

- Cast polyurethane steel plate support quality is very good, through the ISO certification, and now many car manufacturers also in their purchasing as the original parts. You can directly in the Baidu search in Shanghai - and should be able to find Ku - industry, I hope that the answer can help you.

- Q: Can steel props be used in temporary support of mezzanines?

- Yes, steel props can be used in the temporary support of mezzanines. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary support applications. They are designed to provide reliable vertical support and can be adjusted to the required height. Steel props are known for their strength and stability, making them suitable for supporting various structures, including mezzanines. When using steel props for mezzanine support, it is important to ensure proper installation and adherence to safety guidelines to guarantee the stability and structural integrity of the temporary support system.

- Q: Can steel props be used for temporary or permanent support?

- Yes, steel props can be used for both temporary and permanent support. Steel props are adjustable and sturdy, making them suitable for providing temporary support during construction or renovation projects. Additionally, their durability and load-bearing capacity make them a viable option for long-term or permanent support in structures such as buildings, bridges, and other infrastructure.

- Q: What are the common safety training requirements for using steel props?

- The utilization of steel props necessitates adherence to several safety training requirements. These include: 1. Proper handling techniques: Training sessions should encompass safe lifting, carrying, and transporting of steel props to prevent strain and injury. This involves understanding weight limitations and utilizing appropriate lifting equipment when necessary. 2. Inspection and maintenance: Workers should receive training on inspecting steel props for signs of damage or deterioration before use. This entails checking for cracks, bends, rust, or any other defects that may compromise the structural integrity of the props. 3. Assembly and disassembly procedures: Proper training should be provided on correctly assembling and disassembling steel props. This entails understanding the correct sequence of components and ensuring secure connections. 4. Load capacity and weight distribution: Workers need to be educated on the maximum load capacity of steel props and how to evenly distribute weight to prevent overloading or instability. This knowledge is crucial for maintaining a safe working environment. 5. Stability and bracing: Training should emphasize the importance of providing adequate stability and bracing for steel props. Workers must understand how to properly secure props to prevent accidental collapse or movement during use. 6. Personal protective equipment (PPE): Safety training should include the requirement of wearing appropriate PPE, such as hard hats, safety goggles, gloves, and steel-toed boots, when working with steel props. 7. Emergency procedures: Workers should be trained on the appropriate emergency procedures in the event of accidents or incidents involving steel props. This includes knowing how to safely evacuate the area and administer basic first aid if necessary. In summary, safety training for the use of steel props should prioritize raising awareness, teaching proper handling techniques, and ensuring compliance with safety guidelines. This will help minimize the risk of accidents and injuries in the workplace.

Send your message to us

Scaffolding System Ringlock Scaffold Vertical

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords