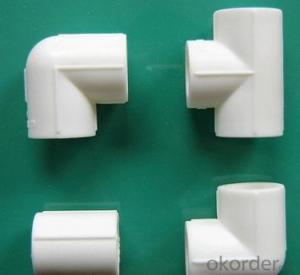

Savko Plastic Pipe & Fittings Reducing Elbow for Industrial Fields

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details

Material: PP-R

Technics: Forged

Type: Elbow

Model Number: DSE901-902

Connection: Welding

Shape: Equal

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~25

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Can plastic pipe fittings be used in oil and gas applications?

- Yes, plastic pipe fittings can be used in oil and gas applications. Plastic materials like polyethylene and polypropylene are commonly used in these industries due to their corrosion resistance, durability, and cost-effectiveness. Plastic pipe fittings can effectively handle the pressure and temperature requirements of oil and gas systems while providing reliable performance and longevity. However, it is important to choose fittings that are specifically designed and certified for oil and gas applications to ensure safety and compliance with industry standards and regulations.

- Q: Can plastic pipe fittings be used in fire sprinkler systems?

- Yes, plastic pipe fittings can be used in fire sprinkler systems. However, it is important to note that the specific type of plastic used must meet the required standards and regulations for fire safety. Certain plastics, such as CPVC (Chlorinated Polyvinyl Chloride), have been approved for use in fire sprinkler systems due to their fire-resistant properties. It is crucial to consult with professionals and adhere to local codes and regulations when selecting and installing plastic pipe fittings in fire sprinkler systems.

- Q: Are plastic pipe fittings compatible with different pipe diameters?

- Yes, plastic pipe fittings are generally compatible with different pipe diameters as they are designed to be versatile and accommodate various pipe sizes.

- Q: Can plastic pipe fittings be used for wastewater treatment facilities?

- Yes, plastic pipe fittings can be used for wastewater treatment facilities. Plastic pipe fittings are commonly used in wastewater treatment facilities due to their corrosion resistance, durability, and ease of installation. Additionally, plastic fittings are cost-effective and offer excellent chemical resistance, making them suitable for handling various wastewater treatment processes.

- Q: Can plastic pipe fittings be used in desalination systems?

- Yes, plastic pipe fittings can be used in desalination systems. Plastic materials such as PVC, CPVC, and polypropylene are commonly used in desalination plants due to their corrosion resistance, durability, and cost-effectiveness. These plastic pipe fittings are suitable for transporting and distributing seawater, brine, and other chemicals used in the desalination process.

- Q: What are the common testing methods for plastic pipe fittings?

- Some common testing methods for plastic pipe fittings include pressure testing, leak testing, visual inspection, dimensional verification, and material analysis.

- Q: How do you connect plastic pipe fittings together?

- To connect plastic pipe fittings together, you typically use solvent cement. This adhesive is applied to the outside of the pipe and the inside of the fitting, and then the two pieces are pressed firmly together. The solvent cement creates a strong bond that securely holds the fittings in place.

- Q: Can plastic pipe fittings be used for chemical mixing systems?

- Plastic pipe fittings can be used for chemical mixing systems, but it is important to consider the specific chemicals involved and choose fittings that are compatible with them. Some plastic materials may be more resistant to certain chemicals than others, so it is necessary to ensure that the chosen fittings are suitable for the chemicals being mixed to prevent any chemical reactions or degradation of the fittings.

- Q: How do plastic pipe fittings compare to HDPE fittings?

- Plastic pipe fittings and HDPE fittings are both commonly used in various applications. However, HDPE fittings are generally considered to be superior due to their higher strength, durability, and resistance to chemical corrosion. HDPE fittings also have a longer lifespan and are more cost-effective in the long run.

- Q: Are plastic pipe fittings compatible with different pipe materials?

- No, plastic pipe fittings are generally not compatible with different pipe materials.

Send your message to us

Savko Plastic Pipe & Fittings Reducing Elbow for Industrial Fields

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords