Teranap Geomembrane - Saltworks High-Quality, Low-Priced Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

Our product was proved as good mechanic performance, high tearing resistance, strong deformation adaptability, puncture, aging,

ultra-violet radiation, high and low temperature resistance, good waterproof, drainage, anti-seepage , complete width and thickness

specifications, low cost and simple construction.

1.used in landfill caps

2. base liner applications under roads, railways,

3.They are also used for waterproofing of buildings and other similar structures.

2.Product Characteristic:

1),Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial,

hospital solid waste, etc.) .

2),Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart,

slope protection, etc.).

3), Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining,

etc.).

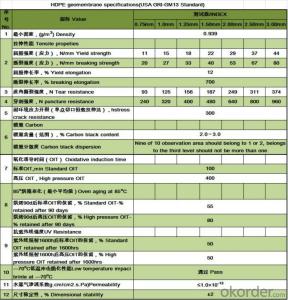

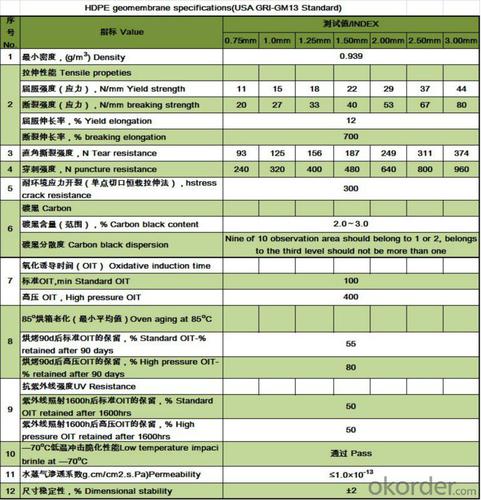

3.Product Specifications:

1.Thickness : 0.1mm---3mm,

2.Length: 50 m -100 m ; width: 4 m -8 m ( according to customer needs )

3.Elongation at break 600%

4.Material: HDPE.

5.Color: Black or as required

4.Reference Picture

- Q: Are geomembranes suitable for use in geothermal energy projects?

- Yes, geomembranes are suitable for use in geothermal energy projects. Geomembranes are impermeable liners that are highly resistant to temperature and chemical corrosion, making them ideal for containing and managing fluids in geothermal applications. They can effectively prevent fluid leakage and contamination, ensuring the safety and efficiency of geothermal energy projects.

- Q: Geomembrane classification

- Seen from the naked eye, particulate is because the feed back material is added too much. Secondly, take samples of the material on site and sent to relevant national authorities to be tested, while adding too much back material will cause the HDPE membrane not reaching American standard index, indicating that the material is not very good, but one thing you can see, as well as some granular things, sand holes on the membrane, which is difficult to distinguish

- Q: What are the considerations for geomembrane installations in areas with high seismic activity?

- When installing geomembranes in areas with high seismic activity, several considerations need to be taken into account. Firstly, the geomembrane material should be selected based on its ability to withstand seismic forces and potential ground movements. High-quality, flexible geomembranes that can accommodate ground deformations are typically recommended. Secondly, the design and installation of the geomembrane system should include appropriate anchoring and attachment methods to ensure that the geomembrane remains in place during seismic events. This may involve using additional fastening techniques such as anchor trenches, concrete collars, or ballasting to secure the geomembrane. Thirdly, the subgrade preparation and compaction should be done meticulously to provide a stable base for the geomembrane. Proper compaction techniques and reinforcement measures, such as geotextiles or geogrids, can enhance the stability of the subgrade and reduce the potential for differential settlement or slope failure during seismic activity. Lastly, regular inspections and monitoring of the geomembrane system should be conducted to identify any signs of damage or displacement that could compromise its integrity. This can help ensure timely repairs or reinforcement to maintain the effectiveness of the geomembrane in high seismic areas. Overall, the considerations for geomembrane installations in areas with high seismic activity revolve around material selection, anchoring methods, subgrade preparation, and ongoing monitoring to ensure the long-term performance and stability of the geomembrane system.

- Q: Are geomembranes suitable for use in coastal areas?

- Yes, geomembranes are suitable for use in coastal areas. They are often used to prevent erosion, control water flow, and contain contaminants in coastal regions. Geomembranes provide an effective barrier against saltwater and other corrosive elements, making them an ideal choice for coastal applications.

- Q: Are geomembranes suitable for biogas storage?

- Yes, geomembranes are suitable for biogas storage. They are durable, impermeable, and can effectively contain biogas while preventing leaks. Additionally, geomembranes are resistant to corrosion and can withstand the harsh conditions associated with biogas storage, making them a reliable option for this purpose.

- Q: Soft film smallpox box film how to make?

- Production: To use the acrylic boards, plastic sheeting, or other insulating material, i often take use of the double layer 2.5mm black aluminum plate. First, to carve the words you need with the single-sided adhesive paper. Then paste it on sided adhesive paper, and penetrate a drill or hole with the help of electric drill or carving machine(The pitch is according to the size of the word, the general interval is 10-15mm). !

- Q: What are the benefits of using geomembranes in floating islands?

- There are several benefits of using geomembranes in floating islands. Firstly, geomembranes provide a durable and impermeable barrier that prevents the loss of water from the floating island, making it more sustainable for the plants and wildlife inhabiting it. Secondly, geomembranes help to prevent the growth of unwanted vegetation and invasive species, ensuring the ecological balance of the floating island. Additionally, geomembranes offer excellent chemical resistance, protecting the island from contaminants and pollutants. Finally, the use of geomembranes in floating islands allows for easy maintenance and repair, increasing their longevity and overall effectiveness in supporting healthy ecosystems.

- Q: Can geomembranes be used in water treatment plants?

- Yes, geomembranes can be used in water treatment plants. They are commonly utilized as liners for containment and protection of water and wastewater storage facilities, such as ponds, lagoons, and tanks. Geomembranes provide an impermeable barrier, preventing the seepage of contaminants and ensuring the integrity of the water treatment process.

- Q: Is waterproof geomembrane the same as EPDM?

- Not the same, different material

- Q: Which kind of the mobile phone screen protector cleaning solution is better?

- The professional can use the computer screen cleaner, while the ordinary just can use the alcohol. In fact, it is almost like natural gas, you can also blow out the lighter gas in the upper air.

Send your message to us

Teranap Geomembrane - Saltworks High-Quality, Low-Priced Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords