RUBBER VULCANIZING ACCELERATOR NOBS (MBS)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

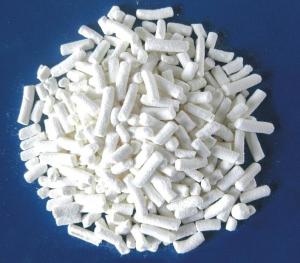

RUBBER VULCANIZING ACCELERATOR NOBS(MBS)

Chemical Name:N-Oxydiethylene-2-Benzothiazole Sulfenamide

Molecular formula: C11H12N2S2O

Molecular Weight:253.35

CAS NO. : 102-77-2

Executive standard:GB/T 8829-2006

Specification:

| Index | ||

High-class products | First-class products | Acceptable end-product | |

Appearance | Faint yellow or orange granules | ||

Initial M.P, oC ≥ | 81.0 | 80.0 | 78.0 |

Loss on drying, % ≤ | 0.40 | 0.50 | 0.50 |

Ash, % ≤ | 0.20 | 0.30 | 0.40 |

Insoluble in Methanol,% ≤ | 0.50 | 0.50 | 0.80 |

Free amine,% ≤ | 0.50 | ||

Purity,% ≥ | 95.0 | ||

Properties: Faint yellow to brown lamellae. 80°C melting point.soluble benzene; carbon tetrachloride; ethyl acetate; ethanol, soluble in dichloromethane; acetone, less petrol, do not dissolve in water. Heating gradual decomposition.

Application:It'after-effect quick accelerator. Scorching time is longer and the processing safety is good.

Packing: 25kg paper bag inner with PE bag

Properties: The product should be stored in the dry and cooling place with good ventilation . The product should be avoid hot sunshine.

- Q: Chemical catalyst system baa?

- Can speed up or slow down the reaction rate without participating in the reaction of the material

- Q: Hydrogen and oxygen in the role of the catalyst can do the chemical formula of aviation fuel?

- You two yeah? Meaning that hydrogen is ignited in oxygen to release energy to push the rocket forward, as the catalyst for those who love,

- Q: Always speeds the reation ratedoes not affect the reation rateundergoes a chemical changedoes not become part of the chemical changealways slows the reation rate

- The best answer is speeds the reaction rate. Generally it lowers the activation energy so that the reaction can proceed easier. Enzymes can be considered catalysts in the body that allow digestion to occur at a temperature like body temp, where it would go faster at a higher temp.

- Q: describe a biological catalyst?

- Enzyme are biological catalyst, proteinous in nature, formed in animal's body by exocrine cell, present in inactive form, generally ends with suffix ase e.g enterikinase with exceptions pepsin, specific in nature not only speed up biological reactions but also lower down the reactions inside the body.

- Q: Is the catalyst in the field of inorganic chemistry?

- The catalyst is a branch of physical chemistry

- Q: How does catalyst aid a chemical reaction?

- A catalyst will change the activation time; in a faster way. Hence the reaction will worke quicker. It is kind of like Nitrous in a car. It speeds up the engine, which would be kind of comparabale to two substances.

- Q: In the catalyst and light conditions to break down the water to get the chemical equation of hydrogen

- 2H2O = (light or catalyst) 2H2 ↑ + O2 ↑

- Q: Is palladium predominantly a catalyst in chemistry?

- Palladium in the chemical mainly to do the catalyst; palladium and ruthenium, iridium, silver, gold, copper and other alloy, can improve the palladium resistivity, hardness and strength, used in the manufacture of precision resistors, jewelry and so on.

- Q: Chemical master invited (about catalyst)

- From the thermodynamics can be reaction, and the three formulas can be added to eliminate the intermediate product, indicating that the reaction may occur. The definition of the catalyst is not complete. I am a junior undergraduate student of Jilin University School of Chemistry, according to the definition of the catalyst in the university textbook, the catalyst itself reacts with the reactants to produce unstable intermediates. After the reaction is finished, the intermediate product is explained and the catalyst is reduced. Apparently did not participate in the reaction. So the catalyst to change the course of the reaction, the original reactants to go through a relatively high energy to produce products, there will be a catalyst after a few relatively low energy barrier, so much easier, the reaction rate is greatly accelerated The It can be seen, the catalyst is not no response, but only after the completion of the reaction to restore it. It can also be seen that the amount of catalyst does not matter, and some reactions require the amount of catalyst to be approximately equal to the amount of reactants. Waiting for you to high school and university to further study on this issue will have a more clear understanding of the.

- Q: Which chemical reaction is added to the catalyst in order to slow down the reaction

- CaC2 and water reaction to ethylene plus salt water (slow chemical reaction rate)

Send your message to us

RUBBER VULCANIZING ACCELERATOR NOBS (MBS)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches