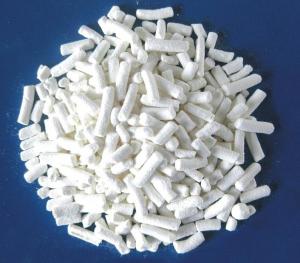

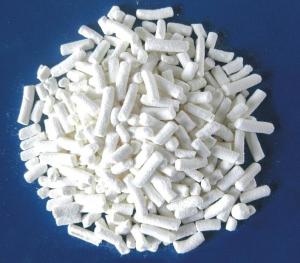

RUBBER VULCANIZING ACCELERATOR CBS(CZ)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 140000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical Name: N-Cyclohexyl-2-benzothiazole sulfenamide

Molecular Formula: C13H16N2S2

Molecular Weight: 264.4

CAS NO. : 95-33-0

Executive standard:HG/T 2096-2006

Specification:

|

Item |

Index | ||

|

High-class products |

First-class products |

Acceptable end-product | |

|

Appearance (Visual inspection) |

Grayish-white, light yellow powder or granules | ||

|

Initial M.P,oC ≥ |

99.0 |

98.0 |

97.0 |

|

Loss on drying,% ≤ |

0.20 |

0.30 |

0.50 |

|

Ash, % ≤ |

0.20 |

0.30 |

0.40 |

|

Residue,% ≤ |

0.00 |

0.05 |

0.10 |

|

In soluble in Methanol,% ≤ |

0.50 |

0.50 |

0.80 |

|

Purity,% ≥ |

97.0 |

96.0 | |

|

Free amine,% ≤ |

0.50 | ||

Properties: Gray, light yellow powder or granules with a little odor, no poison. The density is 1.31-1.34. And melting point 90-108 oC .Soluble benzene, methylene chloride, carbon tetrachloride, ethyl acetate, acetone, ethanol-soluble and petrol do not dissolve in water.

Application: to promote common aftereffect on sexual one. Furnace applicable to the use of black plastic material, both anti-burning performance and excellent short curing time two major advantages. Enable for natural rubber, recycled rubber, vinyl synthetic rubber, especially for the SBR. May be used alone, but also with promoting agent D, DT, TT, TS and others use. Because of a bitter, it can not be used for food-related products. Photochromic minor, do not emit cream vulcanizate excellent anti-aging properties. Used tires, shoes, hose and belt, cable, general industrial products.

Packaging: 25kg plastic woven bag, paper with plastic film bag, Kraft paper bag or jumbo bag.

Storage: The product should be stored in the dry and cooling place with good ventilation, avoiding exposure of the packaged product to direct sunlight. The validity is 1 year.

Note: The product could be ultra fine powder based on customer accurate requirement.

- Q: Does the material profession belong to chemical or chemical class?

- There are two categories: one is subordinate to the mechanical materials, colleges and universities generally put this material professional in the mechanical college, the main research metal materials and mechanical hook; one is chemical and chemical, such as polymer materials Wait.

- Q: What are the basic knowledge of the basic course of material chemistry?

- Polymer chemistry, chemical chemistry, chemical science, physical chemistry, chemical chemistry, materials chemistry, polymer alloys, functional materials, chemistry and physics, crystal growth, chemical engineering, Composite materials and so on.

- Q: Just finished college entrance examination, more interested in chemical disciplines, such as pharmaceutical, food science, materials, these aspects. Do not know which of these employment situation is better, how to pay and work comfort. Thank you can be added. (Note: I am two undergraduate)

- Materials Chemistry students have strong chemical knowledge, material design preparation, testing and analysis of knowledge, can be employed in many areas. Such as electronic materials, metal materials, metallurgical chemistry, fine chemical materials, inorganic chemical materials, organic chemical materials and other materials, chemicals, chemical-related professional. Compared with the chemical, chemical and other professional, materials and chemistry more focus on the development of new materials and applications. At the same time in a number of marginal disciplines such as the environment, drugs, biotechnology, textiles, food, forestry, military and marine areas, materials, chemical professionals have a strong place. Market demand is expected: According to the OKorder "Eleventh Five-Year" development plan: to rely on Yanshan Petrochemical, focusing on the development of environmental pollution filial piety consumption of small, high value-added chemical new materials, fine chemical manufacturing industry, you can see Yanshan Petrochemical, P & G, Shuanghe Pharmaceutical, Sihuan Pharmaceutical and other petrochemicals, fine chemicals, bio-pharmaceuticals and energy companies in OKorder's economic development in the main role, so the material chemistry professional in the next 3 to 5 years of demand should be relatively stable.

- Q: Like we ordinary people how to buy some chemical materials, usually where?

- If it is some explosives (or explosives of raw materials, such as potassium nitrate) or highly toxic to these, with what proof to buy. High school chemistry teacher specifically said that the laboratory of potassium nitrate these things to prove with limited to buy.

- Q: Was a literally raised for several years of school admission, transfer to the material chemistry. High school physics and chemistry is very poor, no interest, learn very laborious. And this is the school opened a new professional, I heard that this is to contact a lot of harmful substances. Feeling very difficult to learn is not suitable for me, after the employment is also a problem. I would have wanted to learn accounting like the degree of professional, learn this fear is to hang the branch.

- Girls do not learn chemical and the like. Even if the issue does not consider the issue, but also consider the health problems. And even learn, and later not necessarily do this work, is a waste of time. University is not so easy to hang the Department. Good preparation before the test, not much of the problem. You can consider the professional category of human resources, partial management, later Ye Hao employment. If you think that repeat can not increase the number, or poor psychological quality, do not repeat it.

- Q: What can I do after the chemistry of materials? The I am learning this, please shrimp pointing

- There are a lot of useful, this is a new discipline, the prospects for a good look. Is it not the aid of the chemistry of the Chinese?

- Q: What is the difference between material chemistry and polymer chemistry in chemistry?

- The polymer material is more focused on polymer chemistry, mainly polymer, such as fiber, rubber and the like, and some relationship with organic chemistry,

- Q: What is the main work of the chemistry of materials after graduation?

- Sales line growth route: salesman → sales director → regional manager → sales director

- Q: What are the chemical materials?

- Polymer is composed of carbon, hydrogen, oxygen, silicon, sulfur and other elements of the molecular weight of the organic compounds of high enough. Known as the polymer, because of its high molecular weight. Commonly used polymer molecular weight in a few hundred to several hundred The effect of high molecular weight on the nature of the compound is that it has a certain strength and can be used as a material, which is also a place where the polymer compound is different from the general compound, and because the polymer compound generally has a long chain structure, All the molecules are like a long line, many molecules together, it becomes a naked thread group, which is the polymer compounds with high strength, can be used as the structural material of the root causes.On the other hand, People can also be through a variety of means, with physical or chemical methods, or the interaction of macromolecules and other substances after the physical or chemical changes, so that the polymer compounds can become a special function of functional polymer materials.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Lianyungang; Tianjin Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

RUBBER VULCANIZING ACCELERATOR CBS(CZ)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 140000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches