Rod Ends Bearings Joint Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

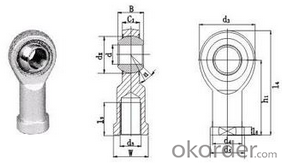

Rod Ends Bearings Joint

Description:

Bearing joints by a the outer spherical inner ring, outer ring and an inner spherical plain bearings of the special structure of the. [1] can withstand heavy loads. The articular bearing structure is simpler than the Rolling mainly by an outer spherical surface of the inner ring, outer ring and an inner sphere. Joint bearings are generally used for the lower speed of the oscillating motion (i.e., angular movement), due to the sliding surface is spherical-shaped, or in a certain angle range, the tilting movement (i.e. aligning movement), the support shaft and the shaft housing bore different heart degree is large, and still work properly.

2. Feaures

(1) Can withstand greater loads. According to their different types and structures that can withstand the radial load, axial load or radial, axial joint load. Since the inner surface of the outer sphere inlaid composite materials, so that the work can be generated in the bearing self-lubricating.

(2) Generally used for slower swing movement, and low-speed rotation, but also for the tilt angle within a certain range of motion, when the supporting shaft and shaft misalignment have large shell hole, it still works. This kind of bearing is used in water conservancy, specialized machinery and other industries.

3. Main Application:

Rod end bearings are generally used for slower swing movement, the movement can be tilted within a certain range of angles. Rod end bearings are widely used in hydraulic engineering, metal forming machine tools, construction machinery, automation equipment, automotive shock absorbers, irrigation machinery and other industry machineries.

F&Q

Q:How long es cycle of bearing life?

A:According to international standards, at least a year and a half , up tu 2 years

Q:How to maintenance bearing

A:Add to lubricantes on time

Q:Have diagram for bearing

A:The small one no have, large bearings will provide diagram

- Q: What is a radial joint bearing?

- B. angular contact radial joint bearings - nominal contact angle greater than 0 degrees, but less than or equal to 45 degrees of radial joint bearings, can bear radial load and axial load simultaneous action of the combined loadJiaxing Solid Bearing Co., Ltd. produces self lubricating radial joint bearings and self lubricating thrust joint bearings

- Q: Why is there a crack in the joint bearing?

- This is determined by the characteristics of the process. Outer single axial joint is the most widely used and the most widely used process.

- Q: Where is the self lubricating joint bearing used on the landing gear?

- Jiaxing solid lubrication is to do self lubrication joint bearings, you can consult them.

- Q: What brands can be purchased for joint bearings?

- InfoQuick bearing joint bearing professional quality, can

- Q: What is the best type of joint bearings in China, such as the model GE 400-DO C3?

- Fujian Longxi bearing Limited by Share Ltd joint bearings are good, but I do not know if you have said that model, you may as well consult them.

- Q: How many kinds of bearings are divided into?

- A lot of ah, a lot of samples are introduced, but you can see the national standard GB/T271-2008 classification of rolling bearings

- Q: Would like to ask about the difference between GE70ES bearings and GEG70ES bearings, and do a good job of relevant literature ah!

- In GE70ES, GE stands for centripetal joint bearings, 70 by the code named E, single slit outer ring, and S has lubricating grooves and holes. GE70ES is the normal series (E Series), omitting annotations;The G in front of 70 represents the dimension series (G Series) in GEG70ES, and the rest are the same as above

- Q: Rod end joint bearings, that is, fish eye bearings, general deflection angle is how many degrees?

- Can not give accurate figures ah, because the joint bearings with size and internal structure does not need, the deflection angle is not the same, generally in more than 7, there are 6.5. There are even 15.

- Q: What brand of bearings are these?

- Pascal explains very well. Schaeffler has a lot of momentum and has been investing several new factories in China recently. The sales are also very strong, and some of them are SKF.

- Q: The difference between self lubricating joint bearings and oil lubricated joint bearings

- Bearings can be divided into self-lubricating bearings and non self lubrication bearings (oil lubrication) two broad categories1. Self-lubricating bearings are made of materials with oil structure. Lubrication is not needed in use, and bearings can be replaced after a certain period of time.

Send your message to us

Rod Ends Bearings Joint Manufacturer China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords