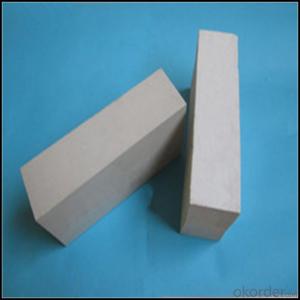

Rock Wool Thermal Insulation Lightweight Refractory Silica Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Item | QG-1.0 | QG-1.1 | QG-1.2 |

SiO2% | 91 | 91 | 91 |

Refractoriness°C | 1680 | 1680 | 1670 |

0.2Mpa Refractoriness Under Load°C | 1480 | 1560 | 1560 |

Cold Crushing Strength Mpa | 3.5 | 3.5 | 3.5 |

True Density g/cm3 | 2.39 | 2.39 | 2.39 |

Bulk Density g/cm3 | 1.0 | 1.1 | 1.2 |

Permanent Linear Change On Reheating(%)1550°CX2h | 0~+0.5 1450°CX2h | 0~+0.5 | 0~+0.5 |

Thermal Conductivity (W/MK) 350°C | 0.55 | 0.60 | 0.65 |

Straight | Split | Arch | Wedge | Tile |

L×W×H(mm) 230×114×65 230×114×75 | L×W×H (mm) 230×114×25 230×114×32 230×114×37 230×114×50 | L×W×H/h(mm) 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65 | L×W×H/h (mm) 230×114×65/45 230×114×65/55 220×114×75/45 220×114×75/55 220×114×75/65 | L×W×H (mm) 230×230×38 230×230×50 230×230×65 230×230×75 |

We also can make brick according to customers’ drawing and requirements. | ||||

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- Rock wool is a traditional insulation material, because it is inorganic materials, insulation performance is not very good

- Q: Rock wool products are divided into several categories

- What are the main categories of rock wool products in interior decoration materials?

- Q: How to judge the quality of rock wool

- Appearance and quality: Choose the material surface smooth and beautiful, no stains, no damage to the material

- Q: The difference between rock wool and rock wool

- The difference between rock wool and rock wool

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Yanmian, mineral wool and its products are slag and basalt and other natural ore as the main raw material, the high temperature melt fiber, adding the right amount of adhesive processing

- Q: Rock wool board is inorganic composite insulation material

- Rock wool board is inorganic composite insulation material

Send your message to us

Rock Wool Thermal Insulation Lightweight Refractory Silica Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords