Rock Wool Quality High Alumina Refractory Brick Homogenized Bauxite Grade for Cement Kilns

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ackaging & Delivery

| Packaging Details: | Wooden pallets with plastic film |

| Delivery Detail: | According to the order quantity |

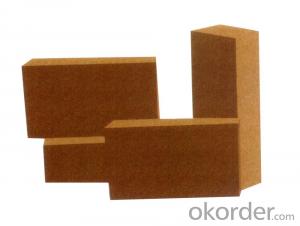

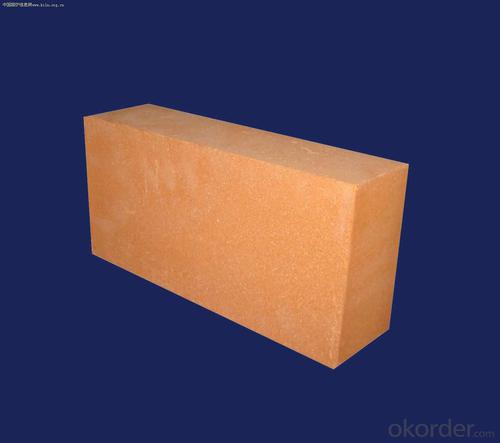

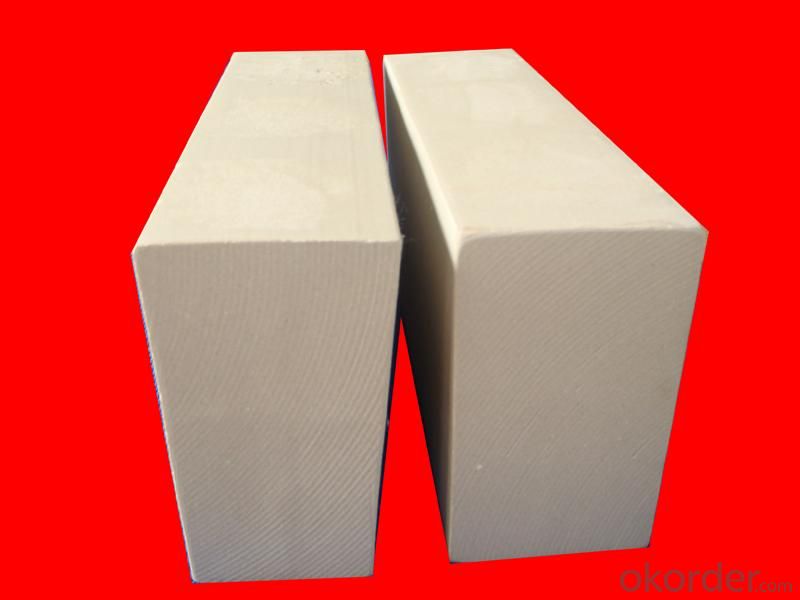

High Alumina Insulating Bricks

Product Description

Applications

The use of the bricks can reduce the heat capacity of kiln walls and promote the heat efficiency of kilns. The product is applicable for constructing industrial kilns and inner lining of kilns.

Typical Features

Produced with unique advanced technology, the clay and high alumina heat insulating bricks possess the characteristics of high intensity for pressure and good thermal shock stability.

Specifications

Brand | High alumina insulating bricks | ||

LG-0.6 | LG-0.8 | LG-1.0 | |

Bulk density g/cm3 | 0.6 | 0.8 | 1.0 |

Crushing strength, Mpa, ≥ | 1.96 | 2.94 | 4.00 |

Reheating linear change within 2% under temperature °C | 1350 | 1400 | 1450 |

Thermal conductivity 350±25°C (W/m.k) | 0.25 | 0.32 | 0.45 |

0.1Mpa refractoriness under load °C, ≥ | 1300 | 1350 | 1380 |

Al2O3 % , ≥ | 50 | 52 | 52 |

Fe2O3 % , ≥ | 1.8 | 1.6 | 1.5 |

Maximum service temperature, °C | 1300 | 1350 | 1380 |

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- What are the main categories of rock wool products in interior decoration materials?

- Q: How to judge the quality of rock wool

- Heat load shrinkage temperature: heat load shrinkage temperature used to characterize the rock wool board moisture and heat stability, is to wet the rock wool product samples soaked in the gradual heating of water, rock wool products at a temperature of 643 degrees will begin to shrink , So rock wool products load shrinkage temperature of 643 degrees, that is to say in the outside temperature of 643 degrees when the rock wool board will be deformed.

- Q: The difference between rock wool and rock wool

- The difference between rock wool and rock wool

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- Rock wool insulation material fire rating is how much

- Q: Rock wool board is inorganic composite insulation material

- Rock wool board is inorganic composite insulation material

Send your message to us

Rock Wool Quality High Alumina Refractory Brick Homogenized Bauxite Grade for Cement Kilns

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords