Rock Wool Reliable Quality High Alumina Refractory Brick with Quick Response

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | Loaded on 1,000 X 1,000 X H700 (mm) pallets. Extensive export track record. |

| Delivery Detail: | Shipped within 1 to 2 weeks after payment is confirmed. |

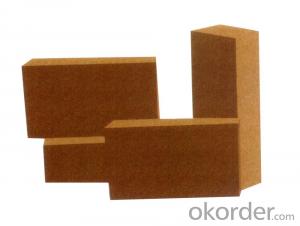

Reliable quality high alumina refractory brick with quick response

- Bricks with superior resistance to wear and corrosion

- Made in Japan for excellent reliability

- Large inventory for fast response

Specifications

Ideal products to use in the lining of a fireplace/inglenook opening, providing fire protection exactly where is needed

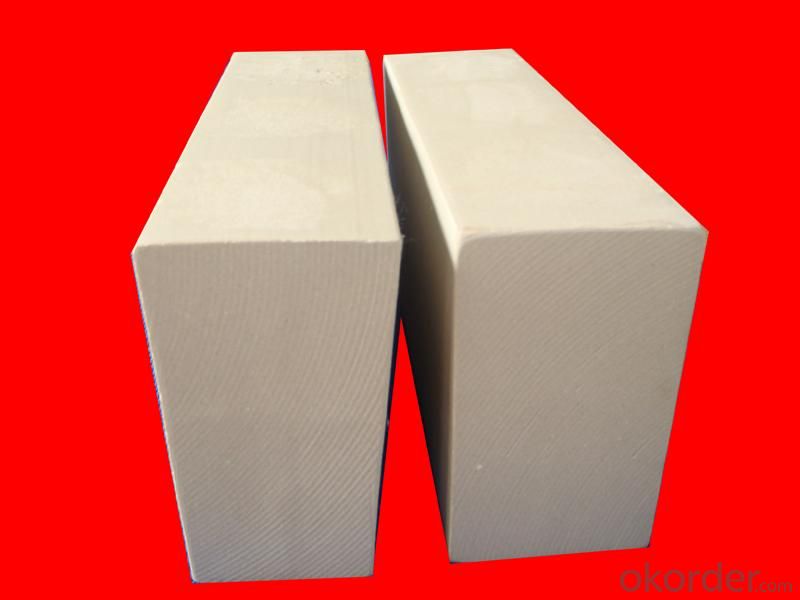

vermiculita tijolo de fogo / Placa do Vermiculite

Vermiculite panels insulate the wall of combustion chamber. They can sustain very high combustion temperatures, which increases efficiency of burning and decreases carbon emissions.

Another characteristic of vermiculite is that it reflects the heat creating powerful radiation. The result is very high efficiency and heat output.

We can supply vermiculite panels/bricks with almost any size, pattern or shape. No matter you want a panel to fit the specific dimensions and pattern, or just want a standard size panel with a decorative face, we all can meet your requirement.

Characteristics:

A1 Grade non-combustible fire rating.

Heat insulation and preservation.

Sound insulation.

Moisture adjustment.

Environment friendly, non-toxic and zero radioactivity, non-asbestos.

Easy to cut and shape with woodworking tools.

Applications:

Fire doors, Fireplaces, Stoves, Storage heaters, Wall cladding, Ceiling, Platforms for marine and vessels etc.

Quick Details

| Place of Origin: | Hebei, China (Mainland) | Shape: | Brick | Material: | vermiculite |

| SiO2 Content (%): | 41.2 | Al2O3 Content (%): | 12.68 | MgO Content (%): | 24.22 |

| CaO Content (%): | 0.96 | Model Number: | vmc-1 | Brand Name: | VMC |

| environment friendly: | non-asbetos | mateiral: | vermiculite | maximum service temperature: | 1100C |

| density: | 400-900kg/m3 |

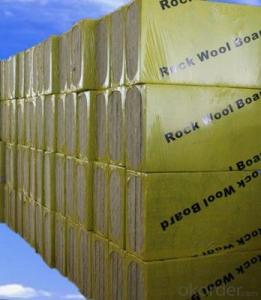

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Appearance and quality: Choose the material surface smooth and beautiful, no stains, no damage to the material

- Q: The difference between rock wool and rock wool

- Yanmian tube is a kind of rock wool insulation material mainly used in the pipeline. After the natural basalt is melted by high temperature, the artificial inorganic fiber is made from the high speed centrifugal equipment, and the special binder and dustproof oil are added. Temperature curing, made into a variety of specifications, different requirements of the rock wool insulation tube

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- With low thermal conductivity, the use of high temperature, fire non-flammable, construction convenience, energy-saving effect is remarkable, there is a high cost performance. Adiabatic with rock wool, mineral wool and its products for a variety of pipe insulation and fire protection

- Q: Rock wool board is inorganic composite insulation material

- Rock wool composite insulation material depends on what you compound the material

Send your message to us

Rock Wool Reliable Quality High Alumina Refractory Brick with Quick Response

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords