Rock Wool Enhanced High Refractoriness Fireproof High Alumina Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

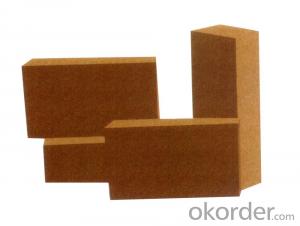

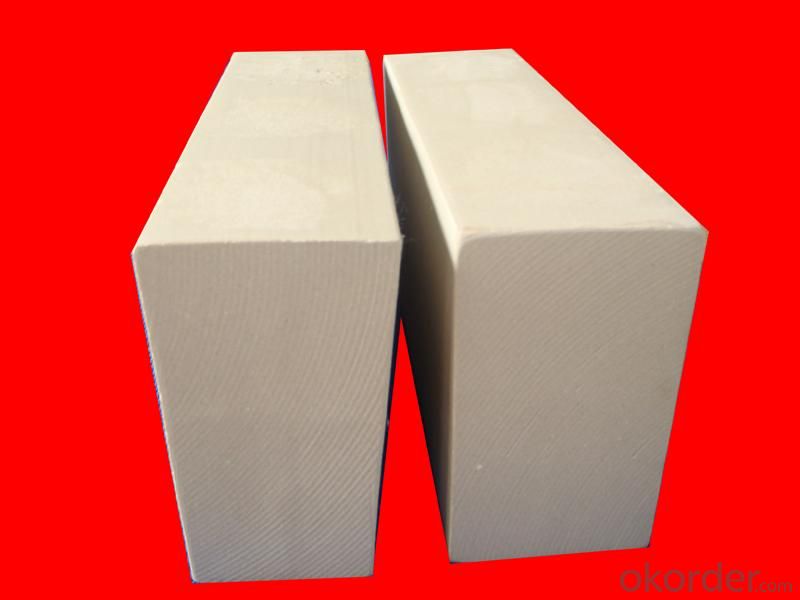

High refractoriness fireproof high alumina refractory brick for heating furnace is made out of a naturally-occurring material known as bauxite. This material include aluminum hydroxide, which is what give the brick such great warmth resistance. High alumina refractory brick also include kaolinitic clays, which are roasted to create an unique combination including mullite and also synthetic alumina. This is where the name “high alumina” stems from.

Features

1.High-temperature endurable .

2.Good thermal shock resistance .

3.High cold crushing strength.

4.Good resistance to abrasion and corrosion.

5.Good thermal spalling resistance.

6.High mechanical strength.

7.Good volume stability at high temperature.

Application

1.General use in heat containment unit form temperature 1500-2000°C.

2.Resistant to highest temperature for steelmaking operations such as ladle applications, sidewall,roofs, burner blocks, anchor brick for reheating furnaces and many other areas.

3.transition and cooling zones of rotary cement kilns, lime kilns , etc.

4.lower sidewall and bottom of aluminum refining,melting furnaces ,etc.

Technical Data

Item | High alumina brick | ||||||

International code name | SK32 | SK34 | SK35 | SK36 | SK37 | SK38 | SK40 |

Al2O3 % | 35 | 42 | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 |

Fe2O3 % | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

Refractoriness °C | ≥1670 | ≥1730 | ≥1750 | ≥1770 | ≥1790 | ≥1790 | ≥1790 |

Apparent porosity % | ≤26 | ≤26 | ≤22 | ≤22 | ≤23 | ≤23 | ≤21 |

Cold crushing strength Mpa | ≥20 | ≥30 | ≥39 | ≥44 | ≥49 | ≥54 | ≥65 |

Refractoriness under load(0.2MPa) °C | ≥1250 | ≥1300 | ≥1420 | ≥1470 | ≥1500 | ≥1520 | ≥1530 |

Reheating Linear Change(1500°C 2h)% | -0.5~0 | -0.5~0 | -0.4~+0.1 | -0.4~+0.1 | -0.4~+0.1 | -0.4~+0.1 | -0.4~+0.1 |

Packaging & Shipping

1. Strong packing will protect the goods from any possible damage during transit.

2. Solid packing and overall stuffing can prevent the cases from vibration and jarring.

3. We must take necessary precaution that the packing can protect goods from pilferage or rain.

4. We can confirm that we take every possible precaution to ensure that our products reach our customers all over the world in prime conditon.

Contact Us

Company Name: China National Building Baterial International Trading Corporation.

Address: No.2, Zizhuyuan South Road, HaiDian District, Beijing City, China .

Post Code: 100044

Tel: 86-10-59042220

Mon-Sun 8:30 AM - 5:30 PM (China Time)

Fax: 86-10-59042275

Email: messimei@okorder.com

- Q: What does the rock wool board look like?

- What does the rock wool board look like?

- Q: What role does dolomite play in rock wool products?

- Polyurethane is a field foam molding, process equipment is simple, easy to operate, you can spray can also be poured, in any complex roof construction operations

- Q: Rock wool products are divided into several categories

- Rock wool with a light weight, non-combustible, small thermal conductivity, sound absorption performance, good chemical stability and so on

- Q: How to judge the quality of rock wool

- Rock wool products, the important content of rock wool products, the density range is kg / m3 100-250 ± 15%, in this density of rock wool board to meet product quality requirements

- Q: The difference between rock wool and rock wool

- Rock wool can also be made with glass wool aluminum silicate composite made of rock wool composite insulation pipe.

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Not a material for insulation, both can be used. The biggest difference is that aluminum silicate acupuncture blanket temperature and insulation effect is better

- Q: Rock wool insulation material fire rating is how much

- Rock wool insulation material fire rating is how much

- Q: Rock wool board is inorganic composite insulation material

- Rock wool board is inorganic composite insulation material

Send your message to us

Rock Wool Enhanced High Refractoriness Fireproof High Alumina Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords