Rock Wool Reliable Quality High Alumina Brick with Quick Response

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shaanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Cement |

| Al2O3 Content (%): | 48%-80% | Model Number: | DFL-LZ | Brand Name: | DFL |

| size: | LZ-80 | apparent porosity: | 22% | refractoriness: | 1790℃ |

| refractoriness under load: | 1530℃ | cold crashing strength: | 55MPa | Al2O3: | 80% |

| thermal shock resistence: | 4-10 | reheating linear change: | 1450℃x2 +0.1 -0.4 | experience: | over than 20 years |

| quality system: | ISO9001-2008 |

Packaging & Delivery

| Packaging Details: | in pallet for sea ship |

| Delivery Detail: | 15-45 days after get customers's deposit |

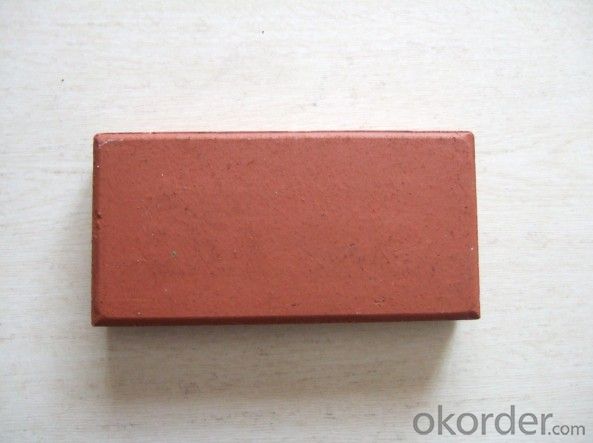

High Alumina Bricks, high alumina refractory bricks, high alumina fire bricks

for general use

description

Specifications of high alumina bricks

1. AL2O3 : 45%-80%.

2. Can according to customers' requirements.

3. Used for steel ladle lining.

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Features of high alumina bricks

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index of high alumina bricks

Common high alumina bricks | NO. | Al2O3 | Fe2O3 | Apparent porosity (Max.)% | Cold crashing strength (Min.)MPa | Refractoriness (Min.)℃ | Refractoriness under load (0.2MPa) (Min.) ℃ | Thermal shock resistence |

LZ-80 | 80 | 2 | 22 | 55 | 1790 | 1530 | 4-10 | |

LZ-75 | 75 | 23 | 53.9 | 1790 | 1520 | |||

LZ-65 | 65 | 23 | 49 | 1790 | 1500 | |||

LZ-55 | 55 | 22 | 44.1 | 1770 | 1470 | |||

LZ-48 | 48 | 22 | 39.2 | 1750 | 1420 |

- Q: What does the rock wool board look like?

- The initial development of Hebei Langfang Dacheng in the building is a common type of application for industrial buildings should be consistent with "building insulation materials, the type of application and basic requirements"

- Q: What role does dolomite play in rock wool products?

- Rock wool is a traditional insulation material, because it is inorganic materials, insulation performance is not very good

- Q: Rock wool products are divided into several categories

- Rock wool with a light weight, non-combustible, small thermal conductivity, sound absorption performance, good chemical stability and so on

- Q: How to judge the quality of rock wool

- Burning performance: Combustion performance refers to all the physical and chemical changes that occur when the building material is burned or in case of fire. This performance is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity And other characteristics to measure. The burning performance of the products of rock wool products is zero.

- Q: The difference between rock wool and rock wool

- Rock wool can also be made with glass wool aluminum silicate composite made of rock wool composite insulation pipe.

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Not a material for insulation, both can be used. The biggest difference is that aluminum silicate acupuncture blanket temperature and insulation effect is better

- Q: Rock wool insulation material fire rating is how much

- Yanmian, mineral wool and its products are slag and basalt and other natural ore as the main raw material, the high temperature melt fiber, adding the right amount of adhesive processing

- Q: Rock wool board is inorganic composite insulation material

- Rock wool composite insulation material depends on what you compound the material

Send your message to us

Rock Wool Reliable Quality High Alumina Brick with Quick Response

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords