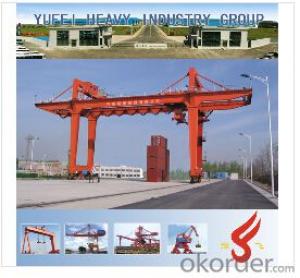

RMG Rail Mounted Container Gantry Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rail-mounted container gantry cranes(RMG) is a specialized yard container handling machine. It can travel on rail by means of the yard power, and lift an stack containers in the yard area with the equipment of the 20' or 40' telescopic spreader (or twin-lift spreader if needed).Compared with the rubber-tyre gantry crane (RTG), the RMG has the advantage of being driven by electrical power, clean, bigger lifting capacity, an high gantry traveling speed with cargo. The RGM consists of lifting mechanism, trolley traversing mechanism, gantry mechanism and sway-dampening mechanism.

The lifting, gantry and trolley mechanisms are mostly equipped with AC frequency conversion control system. Normally the lifting mechanism is of the single drum type.It can also be designed to be double drum type if needed. Our corporation can design and manufacture according to demands of user.

Working condition:

working temperature: -25-40 °C(can be specially designed to -40°C-+40°C)

Lifting capacity under spreader is 30.5t 35.0t 40.5t and 50.0t;

Working duty: A6- A8.

Power source: 380V 50Hz 3Phase. And we can design as your demands.

The altitude height of site is ought to be less than 2000M.

Flammable, explosive and corrosive gas is forbidden in the work environment.

The crane is forbidden to lift fuse and blend deleterious article and flammable explosive article.

Safety:

Overload protection.

Main lifting motor with thermal protection.

Rubber buffers.

Protective earthing.

Anti sway electric system

Crane switch and travel end switch.

Emergency switch can stop all movement when any dangerous happened.

Sub-assemblies characteristic are tested before assembly.

All cranes must be pre-assembled and tested before leaving factory and offer the certification of test.

Features:

Full electric drive technology. Energy saving and environmental protection. Reduce operation and maintenance costs.

Frequency conversion. Accurate locating container and improving working efficiency.

PLC control, which can meet the automation demand of modern container yard.

Tailored designs. Our product will be designed to your container yard most suitably.

Technical Data:

Capacity of Spreader | t | 30.5 | 35 | 40.5 | 50 | ||

Working Duty | A6-A8 | A6-A8 | A6-A8 | A6-A8 | |||

Span(m) | S | 35 | 35 | 35 | 35 | ||

Base(m) | B | 16 | 16 | 16 | 16 | ||

Lifting Height(m) | H | 15.4 | 15.4 | 18.2 | 18.2 | ||

Speed | Hoisting | With Full Load | m/min | 12 | 12 | 18 | 18 |

Only with Spreader | 24 | 24 | 36 | 36 | |||

Travese | 60 | 60 | 70 | 70 | |||

Traveling | 45 | 45 | 45 | 45 | |||

Total Power | kw | ~200 | ~230 | ~255 | ~300 | ||

Max.working Load of Wheel | kn | 260 | 260 | 280 | 300 | ||

Crane Rail | P50 | P50 | P50 | QU80 | |||

Power Supply | 3-phase AC 380v 50Hz or as your demand | ||||||

- Q: This question asks whether building hoists can be used in both indoor and outdoor environments.

- <p>Building hoists can be used both indoors and outdoors, but their usage depends on the specific type and design of the hoist. Material hoists, for instance, are often used outdoors in construction sites to lift materials vertically. On the other hand, dumbwaiters are hoists designed for indoor use, typically to transport goods between floors in buildings. It's important to ensure that the hoist is suitable for the environment in which it will be used, considering factors such as weather conditions, building structure, and safety regulations.</p>

- Q: Explain the distinctions between electric and manual building hoists, focusing on their operation, efficiency, and use cases.

- <p>Electric building hoists are powered by electricity and offer faster operation, greater efficiency, and the ability to lift heavier loads. They are ideal for large-scale construction projects where rapid movement of materials is necessary. In contrast, manual hoists are operated by hand and are typically smaller, more portable, and require human effort to lift materials. They are suitable for smaller projects or where power supply is limited. Electric hoists are more automated and can be controlled remotely, while manual hoists require constant physical effort and are less efficient in terms of speed and load capacity.</p>

- Q: Is it possible to fix a building hoist or substitute it with alternative lifting machinery?

- <p>Yes, a building hoist can be repaired if the damage is not severe. If repair is not feasible or cost-effective, it can be replaced by other types of lifting equipment. There are various alternatives available, such as cranes, forklifts, and material hoists, each with its own advantages and suitable for different scenarios. The choice depends on factors like the weight of the load, the height of the building, and the specific requirements of the construction project. It's essential to consider safety, efficiency, and compatibility with the existing infrastructure when making such decisions.</p>

- Q: This question asks for an explanation of the working mechanism of a building hoist, which is a device used in construction to lift materials and workers.

- <p>A building hoist, also known as a construction hoist or personnel/material hoist, is a temporary lifting device used in construction projects to transport workers and materials vertically within a building. It typically consists of a tower, a cage, a drive mechanism, and a control system. The tower is attached to the building's structure, and the cage is where people or materials are loaded. The drive mechanism, often powered by an electric motor, raises and lowers the cage along the tower. The control system manages the movement, ensuring safety features like speed control and emergency stops are in place. The hoist operates within a guide rail system, which keeps it aligned as it moves up and down the building's height.</p>

- Q: How many kw is the sc construction elevator

- A double cage, the three-drive is 11 * 3 * 2KW and the two drives are 12 * 2 * 2KW

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: What are the necessary maintenance and inspection procedures for hydraulic building hoists to ensure their safe and efficient operation?

- <p>Hydraulic building hoists require regular maintenance and inspection to ensure safety and efficiency. Daily checks should include visual inspections for leaks, proper functioning of controls, and safe operation of the hoist. Monthly inspections should cover the condition of hydraulic hoses, cylinders, and seals. Annual inspections should be conducted by a qualified professional to check the structural integrity, load-bearing components, and overall mechanical condition of the hoist. Regular lubrication of moving parts and replacement of worn components are also crucial. Always adhere to the manufacturer's guidelines and local regulations for maintenance and inspection intervals.</p>

- Q: Is it possible to use a building hoist for lifting heavy materials that cannot be manually lifted?

- <p>Yes, a building hoist is specifically designed for lifting heavy materials that are too heavy or cumbersome to lift manually. These hoists are engineered to handle significant weight loads and are commonly used in construction settings to move materials such as bricks, cement, and steel beams to various levels of a building. They are an essential tool for safe and efficient material handling in construction projects.</p>

- Q: This question asks about the safety measures that should be taken to ensure the safe operation of a building hoist during lifting.

- <p>To ensure the safety of the lifting operation of a building hoist, several key measures should be taken: Regular inspection and maintenance of the hoist equipment to ensure all components are in good working order. Adherence to the manufacturer's guidelines and safety standards for operation. Proper training for operators to ensure they understand how to use the hoist safely. Implementing a safety checklist before each use. Ensuring the load is secured properly and does not exceed the hoist's weight capacity. Using appropriate safety gear such as safety harnesses and helmets. Having a spotter or signal person to assist the operator and watch for potential hazards. Regularly checking the weather conditions to avoid operating in high winds or other adverse weather that could compromise safety.</p>

- Q: Is it possible to utilize a hydraulic cylinder in the construction of a building hoist?

- <p>Yes, hydraulic cylinders can be used in building hoists. They are often employed in lifting systems due to their ability to generate large forces in a controlled manner. Hydraulic cylinders provide smooth and precise control over heavy loads, which is crucial for the safe and efficient operation of a building hoist. They can handle the vertical movement of materials and personnel in construction settings, ensuring a stable and reliable lifting mechanism.</p>

Send your message to us

RMG Rail Mounted Container Gantry Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords