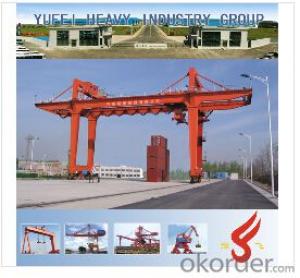

MG450 Rail-mounted Gantry Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

MG450type Rail-mounted Gantry Crane is widely used to carry, hoist or load precast beams at precasting beamyard. The whole machine can run on both longitudinal and transverse tracks by 90°steering of cart running mechanism.

Working Class: A3

Use Level:M4

Rated Lifting Capacity:450t

Span:30m-45m

Lifting Height: 10m-35m

Wheel Press of Cart: 18t-40t

Wheel Press of Trolley: 33t

Lifting speed: 0 — 0.5m/min (heavy load)

0 — 1.0 m/min (no load)

Running speed of cart 0 — 7.5m/min (heavy load)

0 — 15 m/min (no load)

Running speed of trolley 0 — 3.0m/min (heavy load)

0 — 6.0m/min (no load)

Allowable wind pressure ≤250N/ m2 (working),

≤800N/ m2(non-working)

Woking Power: 50H~380V

Overall Capacitance:180Kw~200Kw

Overall Weight:300t – 480t

Working Class: A3

Use Level:M4

Rated Lifting Capacity:450t

Span:30m-45m

Lifting Height: 10m-35m

Wheel Press of Cart: 18t-40t

Wheel Press of Trolley: 33t

Lifting speed: 0 — 0.5m/min (heavy load)

0 — 1.0 m/min (no load)

Running speed of cart 0 — 7.5m/min (heavy load)

0 — 15 m/min (no load)

Running speed of trolley 0 — 3.0m/min (heavy load)

0 — 6.0m/min (no load)

Allowable wind pressure ≤250N/ m2 (working),

≤800N/ m2(non-working)

Woking Power: 50H~380V

Overall Capacitance:180Kw~200Kw

Overall Weight:300t – 480t

- Q: This question asks for a list of various types of lifting equipment commonly used in the construction industry.

- <p>In construction, various types of lifting equipment are utilized to move heavy materials and structures. These include cranes such as tower cranes, mobile cranes, and crawler cranes, which are versatile and can lift heavy loads to significant heights. Forklifts are used for lifting and moving materials over short distances. Telescopic handlers, also known as cherry pickers, provide both lifting and access capabilities. Hoists are used for lifting smaller loads and are often found in workshops or on construction sites. Derricks are fixed structures used for lifting heavy loads in a specific area. Lifting slings and shackles are used in conjunction with cranes and hoists to secure loads. Finally, aerial work platforms, like scissor lifts and boom lifts, provide elevated access for workers and materials. Each type of lifting equipment serves a specific purpose and is chosen based on the nature of the construction project and the weight and size of the loads to be moved.</p>

- Q: why do i dreamt a school thats not mine about tools and machines there were nightmare and also what does it mean to have a nightmarathon and spike to the machin like trying to avoid spikes or something?

- Stop watching the FEAR channel late at night OK their guy?

- Q: in honor of Detroit , ill go with Compton, CA .use D-9 dozers and level the whole place (of course give them 48hrs to leave)and you?

- I would have to say Dallas, just because it is the moon-bat mecca closest to where I live. Ah, the thought of the cockroaches scrambling to get out of the city in time would be a sight to see! I-35 Southbound would be even more congested than usual as illegals made their way toward Laredo! Besides, I could get a long-term contract on that job! $125/hr for dozer or backhoe or $90/hr for bobcat, you choose!

- Q: We just got assigned a term paper in EnglishThe assignment is to read a book or play of our choice by an American author and write an essay on itWe are not restricted in our choice of book or author, but it is recommended that the book have ten pieces of literary criticism available for us to use as sourcesSo I'm thinking that a classic would be the way to goSome that I thought I might consider are.Arrowsmith by Sinclair LewisThe Bridge of San Luis Rey by Thornton WilderThe Red Badge of Courage by Stephen CraneFor Whom the Bell Tolls by Ernest HemingwayThe Sun Also Rises by Ernest HemingwayA Farewell to Arms by Ernest HemingwayAbsalom, Absalom by William FaulknerThe Bell Jar by Sylvia PlathDeath of a Salesman by Arthur Miller Has anyone had any experience with these books/authors? If so, what would you recommend? Oh, feel free to recommend me anything else.

- Hemingway is a boreI liked Red Badge of CourageI'd also branch out from that genre of literature into something a bit moreadventurousTry Robert Heinlein's Stranger in a Strange LandMany of the ideas in that book started the hippie movement back in the 60s, and has symbolism galoreOne of the best science fiction books ever writtenPeople have done doctoral theses on this book.

- Q: give me some examples of formal english text of how to apply?

- Gentlemen:/ I am considering expanding my business and using your compo nay as a supplier. Please send me without charge the following information: (Name the catalogs) Quotes on the following machinery: (List model Numbers) Thank you. Sincerely, John Doe President

- Q: he got Germany out of its depression and they were in worse shape then usand don't say its because he invaded other countries becase he fixed up Germany before the warand i am talking economics

- Hitler did many good things for Germany before he went power crazyHe built massive roads and infustructure projects, dams and bridges, He put everyone to workHe got the machine working.

- Q: I am making a crane(jib) whatever you call it and I have a concept for the crane itself but not for how I will actually move the camera. I heard wires work but I can not seem to grasp teh concept.* It is a heaver camera by the way*

- On a real camera crane you would press the up and down button that moves the wrist part of it. ( I drove a forklift). If you are doing to yourself you'll have to rely on the elbow movements. I might think about renting a Genie lift. And letting someone be your hands in the thing. Unless you know how to build a fully articulating hydraulic ball-joint?

- Q: Im building a new house and i am currently arranging to have the excavator contractor there to install septic and excavate for the foundation. Then im having the foundation contractor come in to do his job. I live in Nova Scotia if that makes any difference. Should any of these guys be asking for money up front or part way through? Or do they finish then bill me with 30 days to pay? Whats the normal procedure?

- I just built a house. I paid the architect after final billing and paid the contractor first a deposit, and from then on had a planned payment schedule of 3 sums with the successful completion of each stage as described in our contract. There was also a final payment for requested extras not included in our quote. Our builder is a very stand up guy.

- Q: the same for a jcb and dump truck please

- Loads skids of course!

Send your message to us

MG450 Rail-mounted Gantry Crane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords