Ringlock Scaffolding Vertical Q235/345 Steel Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ringlock Scaffolding

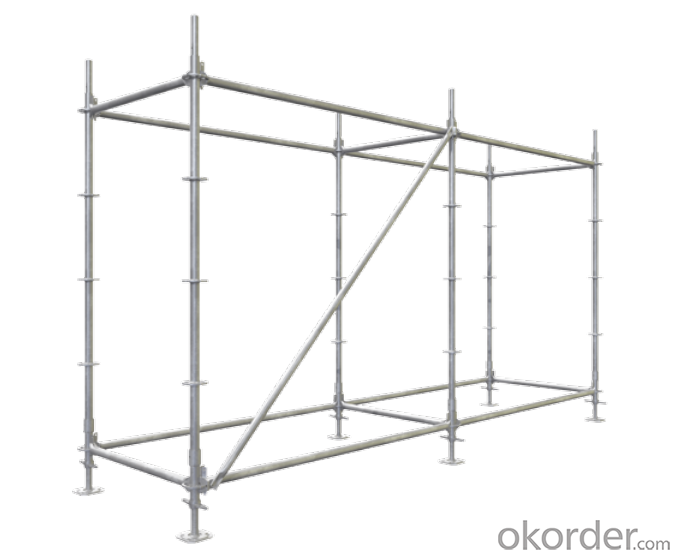

Ring Lock system is the latest item up to now. It’s mainly used in ship building, ship repairing, stage building etc.It’s stable, easy-assemble, easy working, safe-using and with big bearing capacity.

Main Features of the Ringlock Scaffolding

Place of Origin | Beijing, China (Mainland) |

Product Name: | Ringlock Scaffolding |

Custom Code | 7308400000 |

Color | Silver, golden |

Surface treatment | Painted,Hot-Dip,Galvanized,Electro Galvanized, Powder Coating |

Material | Q235,Q345.etc |

Package | Customized Package |

Payment Terms | T/T,L/C |

Delivery Detail | 15-25 Days |

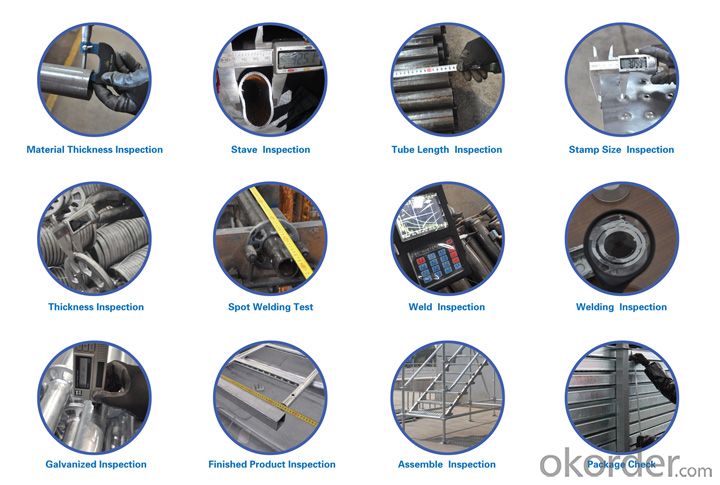

Quality Control | IS09001 Certification, Quality Test |

Standard | 48.3*3.25*4000mm |

Ledger | 48.3*3.25*3072mm |

Ledger End | 1.2kg |

Advantages

1)To be erected easily and quickly

2)Installed to different angels with rosettes of

two different hole being positioned there

3)Ringlock scaffolding provides complete flexibility to lock in any angel.

4)Diagonal braces are to be tailored in

accordance with the lengths of vertical and horizontal tubes

Product Show

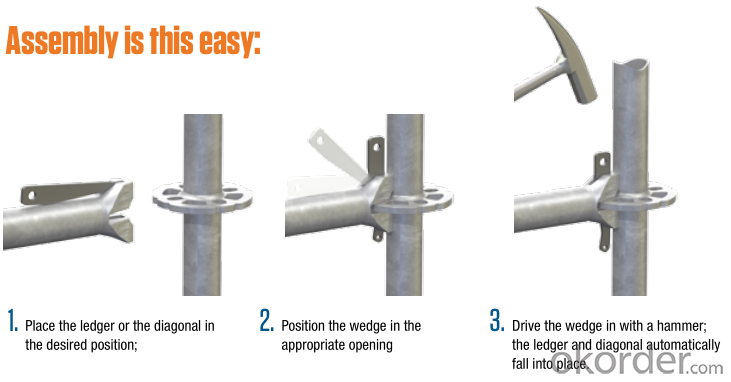

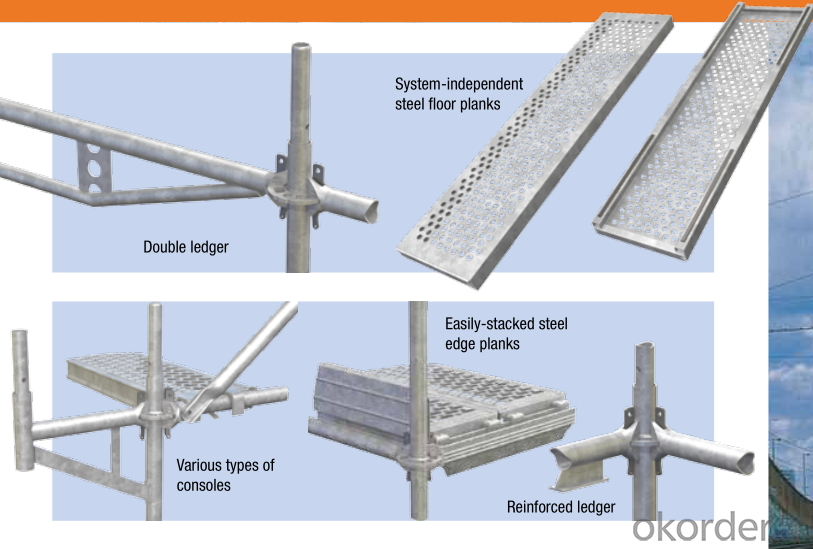

The modular RINGSCAFF system is characterised by the standardised, fast and simple assembly outlined above.

These procedures are continually repeated in the assembly of the scaffold.

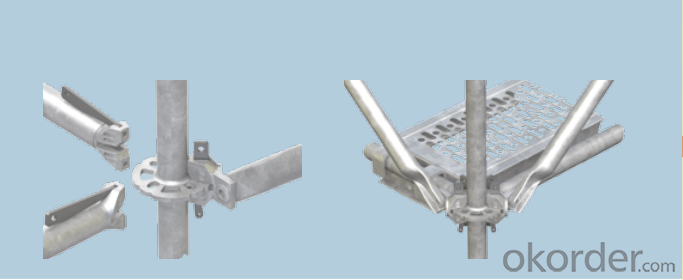

In this way, as many as four ledgers and four diagonals can be attached to one ring! This creates a connection point which can bear very heavy loads.

Specification of Ringlock Scaffolding

The Standards(Verticals) | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

3000 | 3/3.25 | 48 | HDG/Painted | |

2500 | 3/3.25 | 48 | HDG/Painted | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1500 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

500 | 3/3.25 | 48 | HDG/Painted | |

The Ledgers(Horizontals) | ||||

Effective Length(mm) | Tube Thickness(mm) | Tube Diameter | Surface Treatment | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1770 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

The Diagonal Brace | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

2411 | 3 | 48 | HDG/Painted | |

2244 | 3 | 48 | HDG/Painted | |

The bracket | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

730 | 3 | 48 | HDG/Painted | |

Plank | ||||

Effective Length(mm) | Width(mm) | Height(mm) | Surface Treatme | |

2050 | 480 | 45 | HDG | |

1820 | 480 | 45 | HDG | |

3000 | 240 | 45 | HDG | |

2000 | 240 | 45 | HDG | |

1000 | 240 | 45 | HDG | |

Hollow Head Jack And Jack Base | ||||

Length(mm) | Tube Diameter(mm) | Size of Plate(mm) | Surface Treatment | |

600 | 38 | 150*120*50*4 | HDG | |

600 | 38 | 150*150*4 | HDG | |

- Q: Bridge template support bowl button steel scaffolding, you need to set the sweeping rod

- Bridge formwork support bowl buckle type steel pipe scaffold, need to set the sweeping rod.

- Q: I got my scaffolding piercing today, inevitably it's sore,but do i clean it like you would clean normal piercings with salt water?also how long before i can turn the bar?and how long before i can change the bar?Plus. it hurt so much haha

- I got mine about a month ago, but i thought after about a week it didn't really hurt no more and i could rotate it and more recently i can move the bar up and down with no pain. I don't know how long till you can change the bar because i want to change mine because it don't hurt no more, am going to pop into the shop and check. And i didn't clean mine with salt water i got a cleaning solution when i got it pierced and also my piercer gave me a bottle of antiseptic skin paint which i put on twice a week before i go to bed and it is men to help the piercing heal

- Q: I have like 70 frames of scaffold to sell in the dallas area and I don't know where to post it other than ebay and craigslist

- Send me some pics, I may be interested in a few.

- Q: Everybody calls it either one, i want the one that goes across the top of your ear. Would it be safer to have two helix done instead of putting the bar straight in and getting the actual piercing or should i get two helix and put a bar in once it has healed? i would ask the piercer to line the two up. ive heard that industrails go wrong alot if a bar is put right in.

- A standard helix piercing isn't the same as they are on a scaffold. A helix goes front to back where as the scaffold goes through the curl in your ear. A good piercer will do this as 2 seperate piercings with small bars till it's healed. Then fit you with the bigger bar.

- Q: I have already got a cartilage piercing, and I was considering getting a scaffold bar. I don't mind pain, but soon as it was in an unusual place, I was just a little bit curious.

- It's pretty much the same thing. People like to say its really painful, but really its just getting two cartilage piercings in a row. The sting only lasts a second, its not bad at all. you may have a headache afterwards, but thats the worst of it. mainly people say its really bad because its likely they went to a crappy piercing place and didnt really care who pierced them. if you do research and get someone with lots of experience, you should be fine. like my piercer has been doing them for about 15 yrs and does thousands a year. inexperienced ones are the worst. also whats helpful is if you ask the piercer to do one piercing at a time with separate needles, cause some like to do both with the same needle, piercing the second one without pulling the needle out of the first one, which would make it very uncomfortable.

- Q: Did the pageantry of pain at the scaffold actually deter people of crimes during the 18th century?

- Nope. There are plenty of accounts of people sentenced to death for crimes (such as pickpocketing) that they committed AT somebody else's public execution.

- Q: I Got my scaffolding piercied 3 weeks ago i think or 2 , and school starts soon and im doing gcse pe :| loool i need to know how i can hide it ? and if i can just put tape over the balls will they care about the bar in the middle? please help me haha would it be easier to just wear clear balls ? because then im not actually taking the piercing out so it wont get infected or anything?

- Have you got long hair? Tie your hair in a loose ponytail at the bottom of your neck, without putting any hair behind your ears. This is what my friend did for work, it worked for her. The reason you can't wear jewellery in school is 'health and safety', so just having clear balls won't make a difference. Can you get a clear TFT bar as well as balls? that would probably help hide it. Best of luck!

- Q: I got mine done about 10 weeks ago, with the two rings either side of the ear to give it healing space, then about 2 weeks ago, got the bar put through it... but I still can't sleep/lie on it comfortably. How long after getting the piercing, roughly, have people been able to sleep on their without it hurting?

- It takes 6-12 months for a cartilage piercing to heal when done properly with a needle and double that time if a gun was used. I don#x27;t know why they pierced you with rings (should never be used in a scaffold#x2F;industrial piercing) and especially why they changed it to a bar so soon. You should have been pierced with a bar to begin with because changing the jewelry like that causes irritation and prolongs healing time. I think you need to find a different piercer.

- Q: im trying to decide whether the scaffolding ear piercing would suit me or not? how to know? whats the type of look that people with that piercing have?

- These days piercings are so common they'll suit anyone. Not everyone has enough room in their ear for a scaffolding or industrial piercing, so check with a piercer first. It's better to have two separate bars in while it's healing, because if you think about it, the long bar will make sleeping so uncomfortable and will put pressure on the piercings which will not allow it to heal to the best of your body's ability.

- Q: Well my parents are going out of state soon and I want to get a Scaffold Ear Piercing but when i take the earring off does the piecing show?

- you will get your bellybutton pierced or you will get your 2nd ear lobe holes pierced in case you have already got your first ones.. my widespread is the cartilage...I even have my spectacular cartilage pierced and that i like it.. verify you get a small stud nevertheless...you dont wanna seem TOO flashy stable success!!

Send your message to us

Ringlock Scaffolding Vertical Q235/345 Steel Galvanized

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords