Reinforced Concrete Floor Plate Extruder Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Reinforced Concrete Floor Plate Extruder Machine

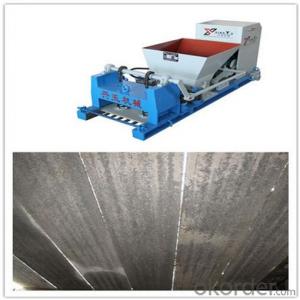

1. Structure of Reinforced Concrete Floor Plate Extruder Machine:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Reinforced Concrete Floor Plate Extruder Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

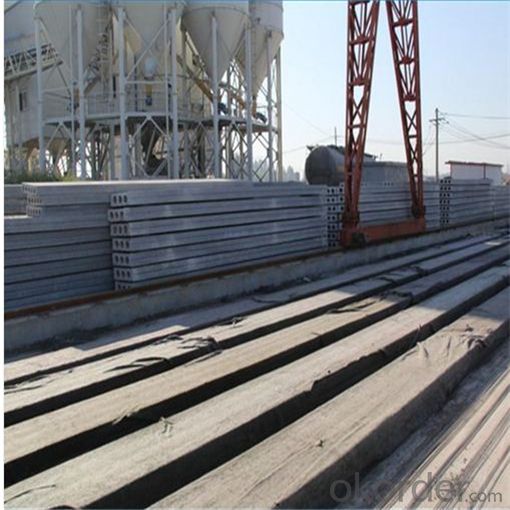

3. Reinforced Concrete Floor Plate Extruder Machine Images:

4. Reinforced Concrete Floor Plate Extruder Machine Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: How to choose mechanical parts material ah?

- The performance of the various materials should be very familiar, and then consult the manual to see what general use in the area.

- Q: I'm specifically looking for training on heavy machinery such as bulldozers, backhoes cranes etc. The courses are given in montreal but there's a 10 year wait. If you know of any sort of training course of the sort in the 613 area code, please let me know. Thanks

- Try okorder /

- Q: Why does the warning label on children's tylenol advise not to operate heavy machinery?

- some adults cannot swallow pills. so we have to take liquids. and sometimes children's is the only option available. i have taken children's tylenol plenty of times in the past few years and i am 20.

- Q: describe the ways in which bacterial machinery can be utilized to replicate mammalian genome?

- NONE NON-EXISTENT WON'T

- Q: Just to find out what it did. Or a good estimate?

- i did once. and somebody got hurt.

- Q: What machinery/tools are need to make custom guns?

- here's a long list of some very expensive machinery gunsmithing lathe wood lathe (lathe for wood) drill press 20 ton press riveter propane torch rifling cutter- a special lathe that only does rifling. for chambers and crowns you use the gunsmithing lathe. bandsaw jigsaw multi-axis mill CNC probably want a 3d printer furnace crucible for casting crimp tool thread tools many kinds of bench vices clamps paint booth bluing tubs electroplating tubs drying ovens belt sander calipers, all kinds of hand tools power drill, power saw, etc dremel tool welder water jet (for cutting metals wood) injection molding, silicon molding, vacuum molding - working with polymers. I wish I had all these at my disposal, I've designed 6 guns that I would love to build. without basic wood shop tools I can't even make a custom stock (a good stock). Still, I managed to make do a few times with my own hobby gunsmithing projects. the work isn't great, but considering I have like no tools its of incredible precision and quality. that like muzzle brake i designed and build for my mosin Nagant. the cutting took 4 months to do (some 300 hours). managed at 0.006 inch accuracy. in comparison, if I had the proper tools it shouldn't take more than an hour. at my school borrowing this 3d printer (wish I could buy one but no way i can afford 384 grand) I printed several prototype actions that shows my ideas but cannot be used as they're made of plastic. I also made several parts for my .22lr rifles that can actually be used. scope mounts, front sight, rear sights, etc.

- Q: Can you convert Auto Cad drawings not Inventor drawings to use with CAM & CNC software & Machinery?

- yes you can i took a AutoCad class and the teacher showed us how to convert AutoCad drawings to mastercam

- Q: what are the machinery in which threads are used for power transmission?

- Ball screws and ACME screws are often used as the means to provide thrust in a linear actuator. Linear actuators are present in many, many applications.

- Q: Framework for oil well drilling machinery?

- Derrick

- Q: why on ship machinery's are installed forward-aft & not port starboard?

- Weight stability would be a primary factor.....You want the weight distributed along the center line

Send your message to us

Reinforced Concrete Floor Plate Extruder Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords