Refractory Raw Materials Converter Tap Hole Stopping-Slag Slide Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Converter Tap Hole Stopping-Slag Slide Plate

Pure zirconia plate is inlayed in the important region of converter tap hole stopping-slag slide plate. The matrix is made of stable medium and high temperature AZC materials,which has long service life, excellent effects of stopping-slag.

Medium or high temperature sintered Sialon bonded sliding gate at N2 atmosphere

Independent research and development of new sliding gate by importing special sialon additives, sintering at the medium our high temperature of N2 atmosphere. In the process of sintering create the sialon phase with good medium or high temperature performance, thus improved the high temperature compression strength and the breaking strength. The using effect on the large and medium-sized steel ladle and the tundish is good.

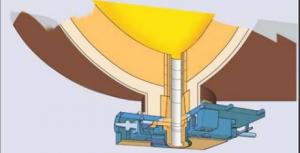

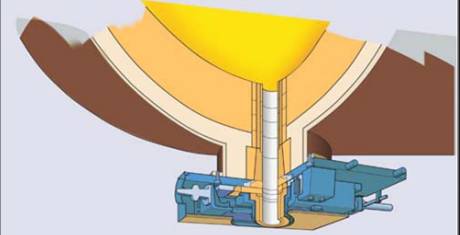

BOF taphole slag slide gate mechanism

Using the mechanism of BOF slag could recovery slag effectively in the furnace. And slag splashing protection technology could increase converter furnace which can solve the problem of irregular erosion in taphole. By the new process of slag controlled tapping , can improve the alloy yield, and can also greatly save the amount of aluminum addiction, the comprehensive cost reduction is considerable, and it also improved the economic efficiency and the competitiveness of the products in the market, it’s the first choice of equipment for smelting high quality steel.

- Q: what kind of refractories is used to make the industrial silicon furnace mouth long life?

- Fused zirconia corundum brick, the smelter of the glassworks is used this kind of lining, and you can contact by private letter.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- 1, first of all, the EIA unit and the construction party signed the EIA contract. The contract is only legally valid. Generally speaking, the contract will indicate that the first payment has been received before the work begins.2. Collecting information. This is a very important link in the EIA, which is directly related to the quality of the eia. There is a great variety of data,Generally, the construction party will write a list of environmental impact assessment information.

- Q: What a blast furnace refractories generally?

- refractories for blast furnace include carbon brick and silicon-aluminum refractory. BF carbon brick inlcudes half-carbon charcoal bricks, microporous charcoal brick, ultra porous charcoal bricks, graphitic brick and mould pressing charcoal brick. tiles and molded graphite small charcoal bricks. I hope my answers above are helpful to you and your ideal anwers.

- Q: what is the fireproofing material of engine room? who knows it ?

- machine room fireproofing materials include: Inorganic binder: The main material includes sodium silicate, gypsum, phosphates, cement,ect.; refractory mineral filler: aluminium oxide, asbestos powder, calcium carbonate, perlite, cornstarch, ect.; nonflammable organic resin: it mainly includes polyvinyl chloride, perchloro-ethylene, chlorinated rubber, neoprene latex, epoxy resin, phenol resin, ect.. nonflammable fireproof addictive: it mainly has phosphorus, halogens, nitrogen organic compounds (chlorinated paraffins, tributyl phosphate,deca-brominated diphenyl ether), and boron series (boric acid, zinc borate, aluminium borate), antimony system, aluminium series, zirconium system, etc. inorganic compounds.

- Q: What are the types of steel refractory materials

- The major category is classified as permanent layer, working lining. Specific varieties: Air permeable brick (corundum). steel ladle brick (magnesia or corundum), permanent layer castable (high alumina), reinforcing material for ladle bottom, repair material for the edge of tank and so on.

- Q: What level is the rock wool board fireproofing material ?

- The most important feature of the rock wool board is fireproofing, which is a non-combustible material and absolute A-level! It has the specialized external wall rock wool board, which can be found online.

- Q: What types of steel are silicious quicksand and chromium quicksand used in respectively?

- Chromium quicksand can be used in steel-making process that has longer refining time like LF, VD and RH, in stainless steel drainage and thin plate drainage agent. Silicious quicksand is used in short steel-making process, process that is less than 45 seconds or process without refining. You can consult Hua Heng for details or inspect it by yourself.

- Q: Who knows the texture of fire-proof wooden door material?

- The so-called fire doors are only posted a layer of fireproof material. Door selection still depends on the timber inside. The simplest way is to see the weight value, fireproof material layer, and they are generally paint-free doors. with fireproofing function..

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Refractory materials used in special applications include high temperature oxcide, such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconia and other, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, mainly contain metal ceramic, high temperature inorganic coatings and fiber reinforced ceramics.

Send your message to us

Refractory Raw Materials Converter Tap Hole Stopping-Slag Slide Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords