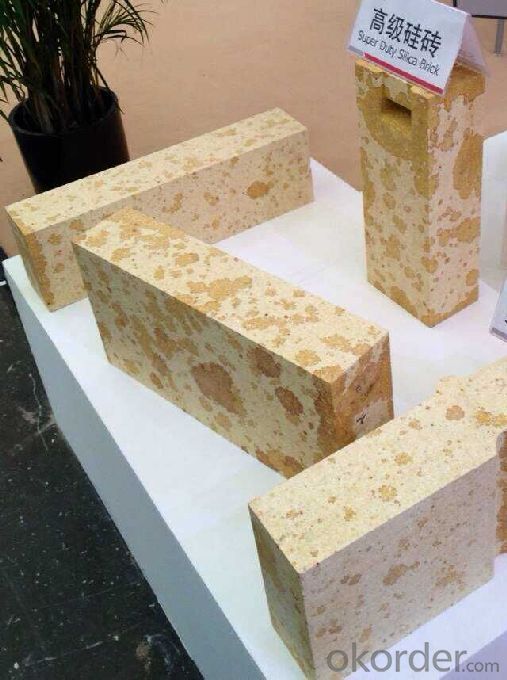

Raw Materials for Refractory:High Density Silica Brick 96B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q: What requirements should refractory materials meet?

- The operating temperature of forging furnace is above 1000, which can ensure the normal operation of the furnace, prolong the life of the furnace and save energy. General requirements for refractories are as follows. 1 They should deform at a sufficient temperature without melting. 2, They should have necessary structural strength without softening and deforming. The volume should be stable at high temperature without expansion, contraction or cracking. 4, They can resist erosion of molten metal, slag, gas and other chemicals.

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- It belongs to material, and after all, more than 60% refractories are used in metallurgical industry. If you insist on classifying it, it belongs to supporting industry of metallurgical industry. Refractory industry itself is independent.

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- Seven characteristics of insulating brick:Insulation and heat insulation: effectively reduce energy consumption.Fire prevention: up to national standard or class A.Clean and environmental protection: no two pollution will be caused by air.Per square metre weighs only about 1.4 kilograms, reduce the burden of building.Simple production: completely break through the traditional process, greatly shorten the construction cycle.Beautiful: can be modulated into a variety of colors, suitable for Ming outfit.Durable: long service life.

- Q: Concrete composition and function of magnesia bond used in refractory

- Mainly high purity magnesia powder and silica fume, in accordance with the 4:1 ratio of the mixture, that is, we often use in the castable MgO-SiO2-H2O binding system! Compared with cement, the content of CaO is lower, the high temperature strength of the product is increased, and the slag corrosion resistance of the product is increased!

- Q: How to classify the grade of wall fireproof and thermal inuslation matertial?

- External wall thermal insulation materials are mainly divided into grade A, grade B1, grade B2 and grade B3. In accordance with the current "Combustion Performance Classification Method of Building Materials", grade A thermal insulation material is incombustible?material and belongs to inorganic heat preservation material. However, grade A thermal insulation material is few in terms of the current market. There are only JETCO YT inorganic active wall thermal insulation material, glass wool, rock wool board, foam glass, vitrified micro bead and grade A fireproofing thermal insulation board. However, compared with grade A thermal insulation material, the more welcomed by the market is the organic insulation materials. Thermal insulation material that is determined as grade B is divided into three levels. Grade B1 is grade is flame retardant. Grade B2 is combustible. Grade B3 is flammable.

- Q: What is the role of the vermiculite fireproof material?

- It can be widely used in construction, decorative ceiling, wall, floor and fireproof door . Especially suitable for airport, railway station, passenger terminal, exhibition hall, hotels, shopping malls, hotels, and other public places and factory, fuel warehouses which have high requirements for fire proofing, etc. With its special thermal insulation, it can also be made to the various types of heat insulation board offered to machines (such as a variety of industrial furnace and assembly line equipment) and furniture, etc. Due to the low density of the product itself, a lot of shipyards in foreign countries use it as ceiling, wall and deck, so the development potential of the domestic shipbuilding market is huge.Expanded vermiculite is porous, lightweight, and dystectic, the most suitable for insulating materials at high temperature (below 1000℃) and fire insulation materials. In the experiment, 15cm- thick cement vermiculite burns for 4-5 hours under 1000℃, but the back temperature is only 40℃. 7 cm-thick vermiculite slate burns for 5mins through the fire flame welding net under 3000℃, the frontage melted, but you don’t feel hot with your hands holding the back side. According to aforementioned, vermiculite slate is superior than all insulating material, such as asbestos, and diatomite products.

- Q: How is refractory material made?

- It is made from carbon materials.

- Q: What's the heat conductivity coefficient, specific heat capacity and density of the refractory material of magnesite-chrome brick and magnesia-alumina brick respectively?

- It is suggested that you find some samples of well-known manufacturers, such as Ogilvy and Mather Group, and that will be more correct.

- Q: How to make the service life of refractory materials longer?

- Take acid resistant refractory materials as example: the atmosphere should be acidic atmosphere, if used in an environment whose temperature is 1900℃, it would exacerbate the loss of refractory materials, so don’t use overloaded. Second, select the appropriate refractory materials according to the environment. For example, if its operating temperature is 1800℃, generally speaking, the normal use of it according to the instruction of refractory materials would be fine.

Send your message to us

Raw Materials for Refractory:High Density Silica Brick 96B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords