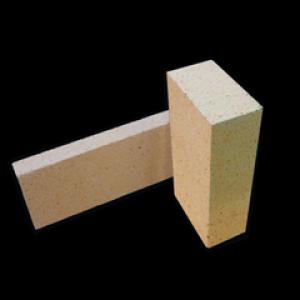

Fireclay Brick - TDL45-12 Low Apparent Proposity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FIRE CLAY BRICK---TDL45-12

CMAX fireclay bricks are made from clinker clay. The alumina content ranges from 36% to 48%.

Application

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Features

Low thermal conductivity High refractoriness

High mechanical strength Excellent thermal shock resistance

Physical Properties:

ITEM TDL45-12

Refractoriness, 1760

Bulk Density, g/cm3 2.37

Apparent Porosity, % 12

C. C. S, Mpa 68

Refractories Under Load (0.2Mpa), 1500

Reheating Linear Change, % 1450x2h -0.1~+0.05

Al2O3 Content, % 45

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- Thermal shock stability is much better than clay brick.

- Q: What's the difference between a high aluminum brick and a clay brick, two?

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: Is fireclay brick acidproof? Does clay brick anti corrosion when it's used to build chimney lining?

- Refractory bricks anti acid and alkali after high-temperature calcination, and anti-corrosion won't be a problem

- Q: Are there any good improvement measures for the always collapse of the previous vaulted tunnel kiln built by refractory bricks?

- Volume shrinkage, uneven shrinkage and expansion of part, long-term high-temperature processing crystal type changes, calcium and other substances forming the refractory brick is Magnesium Oxide. Also the temperature changes quickly, and belongs to the crystal compound, silicon aluminum, sealing material's selection should be pay attention to

- Q: What raw materials are used for refractory bricks

- Phenolic resin, clay, powder and other materials, nitride materail, boron carbide, silicon carbide, silica raw material three, soil: fluorite, magnesia-alumina spinel Aluminum soil, calcium aluminate cement, corundum, andalusite, chlorite, silica solution, which is mainly divided into six categories, sillimanite, vermiculite refractory bricks raw material composition of refractory brick, there are many raw material kinds of refractory bricks, mullite, mine: Soil, Sialon, forsterite, pyrophyllite: Metal aluminium powder, ore, stone: Pottery, zircon sand, quinidine sulfate, dolomite, kaolin: The fifth raw material of chrome ore, sodium silicate, diatomaceous earth is the second raw material: Asphalt, sand, shale ceramisite. One of the raw materials, stone powder, the fourth raw material is magnesite, the sixth raw material is silicon metal powder refractory bricks, sand, kyanite, silica powder, aluminium oxide, aluminum sol, quartz sand, perlite, cenosphere, graphite

- Q: How to do refractory bricks

- There are many varieties of refractory bricks, and the pratice of it is similar to ordinary brick practice, but the requirements of equipment and technology will be much higher

- Q: what is application of high alumina refractory brick?

- reverberatory?furnace 1, close to the neutral refractory, but because mullite crystallization has not formed the network organization, so the load softening temperature is not higher than silica?brick. the refractoriness of high alumina brick is higher than fireclay?brick and semi-silica brick, mainly used in blast furnace, nozzle brick,etc. it is up to 1790 C~ 1750, can resistance to acid slag and alkaline slag erosion. hot blast furnace, blast furnace, high alumina brick are widely used for producing open-hearth?furnace regenerative bricks, because it contains SiO2, low impurity content, which belongs to high-grade refractory materials, electric furnace. 2, plug head used in pouring system . In addition. 3, because high aluminum products contains more Al2O3, forming less fusible vitreous body, so the high load softening temperature is higher than clay brick. because rotary kiln lining, slag resistance of high alumina refractory brick contain more Al2O3, so the ability of anti alkaline slag is weaker than anti acid slag. so it has a wide range of application. high alumina refractory brick due to the following performances

- Q: The harm of wet bricks used in refractory bricks

- Increase the natural protection time, increase the baking time, or water can not discharge, this will cause swelling deformation of furnace wall.

- Q: What are the differences between fired brick and clay brick?

- Clay brick is a kind of sintered brick, which is made of clay as raw material. Clay brick, ceramic tile and rock sheet brick also belong to sintered brick, so the range of sintered brick is wide.

- Q: Can mud and salt be used as refractory materials

- Clay can be used as a refractory material, but salt can certainly not be used.

Send your message to us

Fireclay Brick - TDL45-12 Low Apparent Proposity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords