Refillable Can Tin Can For Shaving Foam, Aerosal Can

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

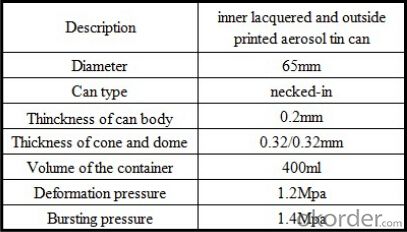

1.Brief description

2.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

3.Packing

4.Advantages of us

1.With ISO9001:2008 certification

2. Over 20 years in producing tin cans

3. Annual capacity: over 400 million pcs

4. Introduced the most advanced iron-printing machine from Japan and Germany, also several full-automatic & high-speed(300pc/minute) can-making lines from Europe.

5. Our products include diameter 45mm, 52mm, 57mm, 60mm, 65mm, 70mm, the can height is from 80-300mm differently

5. FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What are the different ways to open tinplate cans?

- There are a few different ways to open tinplate cans. The most common method is using a can opener, either a manual one or an electric one. Another way is by using a knife or a pair of scissors to puncture and cut open the lid. Some cans also have pull-tab lids that can be easily opened by pulling the tab upwards. Lastly, there are specialized tools like a claw hammer or a multi-tool that have a prying function to open cans.

- Q: Can tinplate be used for high-speed packaging lines?

- Yes, tinplate can be used for high-speed packaging lines. Tinplate is known for its strength, durability, and ability to withstand high-speed production processes. It is commonly used in the packaging industry for various applications, including food and beverage cans, aerosol containers, and metal closures. Its smooth surface allows for efficient movement on conveyor belts, and its resistance to corrosion ensures product safety and longevity. Overall, tinplate is an excellent choice for high-speed packaging lines due to its reliability and compatibility with automated production systems.

- Q: What are the main challenges in tinplate coating thickness control?

- One of the main challenges in tinplate coating thickness control is achieving uniformity across the entire surface of the tinplate. The coating thickness must be consistent and within the desired range to ensure proper protection and functionality of the tinplate. Additionally, controlling the coating thickness requires precise measurement and monitoring techniques as well as the ability to adjust the coating process parameters in real-time to account for any variations or deviations. Another challenge is ensuring the adhesion of the coating to the tinplate surface, as poor adhesion can lead to coating defects and reduced performance. Lastly, controlling the coating thickness while maintaining cost-effectiveness can be a challenge, as it requires optimizing the coating process to minimize material waste and reduce production costs.

- Q: What are the different tinplate surface finishes?

- Some common tinplate surface finishes include bright finish, stone finish, and matte finish.

- Q: What are the potential health risks associated with tinplate?

- The potential health risks associated with tinplate are primarily due to the possibility of tin and other metals leaching into food or beverages stored in tinplate containers. Some studies suggest that high levels of tin exposure may lead to stomach and intestinal issues, such as nausea, vomiting, and diarrhea. However, the overall health risks are considered low, as strict regulations and safety measures are in place to minimize these concerns.

- Q: What are the typical transportation requirements for tinplate?

- The typical transportation requirements for tinplate involve careful handling to prevent damage or denting, as well as protection from moisture to avoid rusting. Tinplate is often transported in specialized packaging or containers to ensure its safety during transit. Additionally, the transportation process should consider the weight and volume of the tinplate to determine the appropriate mode of transportation, whether it be by truck, rail, or sea.

- Q: What are the transportation considerations for tinplate?

- Transportation considerations for tinplate include ensuring proper packaging and securing the tinplate to prevent damage during transit. Due to its susceptibility to corrosion, tinplate should be protected from moisture and extreme temperatures. Additionally, the weight and size of tinplate may impact the choice of transportation method and require careful handling to prevent accidents or injuries.

- Q: Can tinplate be used for art and sculptures?

- Yes, tinplate can be used for art and sculptures. Its malleability and durability make it a suitable material for creating various artistic forms and sculptures. Additionally, tinplate can be easily manipulated, painted, and decorated, allowing artists to explore their creativity and produce unique artworks.

- Q: How is tinplate coated for beverage cans?

- Tinplate is coated for beverage cans through a process called electrolytic tinplating. In this process, a thin layer of tin is electroplated onto the surface of the steel sheet. The steel sheet is first cleaned and then passed through an electrolyte solution containing tin salts. An electric current is then applied, causing tin ions to be reduced and deposited onto the steel surface, forming a protective and corrosion-resistant tin coating. This tin coating ensures that the beverage cans remain safe and free from any metallic taste.

- Q: How does tinplate perform in terms of heat transfer?

- Tinplate performs poorly in terms of heat transfer compared to other materials.

Send your message to us

Refillable Can Tin Can For Shaving Foam, Aerosal Can

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords