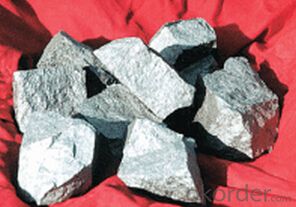

RE FeSi For Casting Manufactural

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1 Type: 15#

2Size: 48mesh 200mesh 48D 270D 0-3mm

3We can do CIQ & SGS quality certification according to customer requirement

Applications

1 Milled Ferro Silicon 15# is a magnetic ferro silicon produced in electric arc furnaces and subsequently milled to size ranges required. In addition, Milled Ferro Silicon contains aluminum and titanium which enhances its resistance to corrosion.

2 Milled Ferro Silicon 15# is used in slurry density applications for heavy media separation and sink-float processes. Powdered Ferro Silicon is an accepted medium for the gravity separation of minerals, aggregates and metals with a specific gravity of approximately 2.0 to 4.0.

3 Milled Ferro Silicon 15# is used extensively in the dense media separation process in both the metal recycling and mining sectors.

Chemical Content

FE | Si | Ti | Al |

70-85% | 12-18% | 0-8% | 0-3% |

Data Sheet

Product Designation(mesh) | +48 | +65 | +100 | +150 | +200 | +325 | -325 | ||

Particle Size(micron) | Percentage by mass | ||||||||

48MESH | 0-6 | 0-8 | 6-14 | 14-22 | 17-25 | 22-30 | 14-22 | ||

65MESH | 0-4 | 0-6 | 3-11 | 11-19 | 15-23 | 25-33 | 23-31 | ||

100MESH | 0-2 | 0-4 | 0-6 | 80-90 | 0 | 0 | 0 | ||

200MESH | 0 | 0-2 | 0-2 | 0-4 | 4-12 | 30-80 | 0 | ||

48D | 0 | 0-2 | 1-9 | 10-18 | 14-22 | 27-35 | 27-35 | ||

65D | 0 | 0 | 0-2 | 0-6 | 4-15 | 29-33 | 47-55 | ||

100D | 0 | 0 | 0-2 | 0-3 | 0-7 | 25-33 | 61-69 | ||

150D | 0 | 0 | 0-1 | 0-1 | 0-4 | 16-24 | 73-81 | ||

270D | 0 | 0 | 0 | 0-1 | 0-3 | 5-13 | 85-93 | ||

0-3MM | -- | -- | -- | -- | -- | -- | -- | ||

- Q: Detailed comparison of cemented carbide with diamond properties

- Diamond is hard and brittle, with excellent performance, most of the material processing, as is the emerging industry, the production level is uneven, the high price range; processing hard alloy is less, the price is relatively cheap, because it is a traditional industry, level of production is relatively mature. If you are now worried about the choice of a tool for processing, using diamond tools or carbide tools?

- Q: What are the differences between the two grades of carbide, YT15 and YT5?

- YT15 is compared to YT5. The former has high hardness, great brittleness and good wear resistance. The latter is low in hardness, tough in toughness and poor in wear resistance.

- Q: The existing 60*60 standard cast iron plate, above 3 hard alloy welding specifications, probably in the 30*30, in which the appropriate welding method, know the friends willing to enlighten ah, thanks in advance.Some friends have said the binder is a copper brazing, the basic can be settled. As far as I know, many methods such as welding, high frequency welding, oxygen welding, I want to find a kind of welding method. The key is to understand the trouble with us, surface and surface welding

- Welding hard alloy is the most used for brazing, welding of copper wire.

- Q: What are the well-known brands of cemented carbide materials at home and abroad?

- Foreign - Sweden Sandvik, Germany - Luxemburg, American Kenna, Israel - Domestic - hard line iscar; diamond, Zigong the Great Wall, Xiamen gol-egret etc..Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q: Why is carbide cutting tools less standard than high speed steel cutting tools?

- Because the hard alloy material rigidity is better, the brittleness is bigger, the toughness is relatively bad, namely is easier than the high speed steel cutting tool to break off, after grinding blunt, the force is more complex. Greater resistance.Cemented carbide: an alloy material made from powder metallurgy by hard metals and bonded metals of refractory metals. Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Now, the cutting speed of new carbide tools is several times that of carbon steel. Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: Carbide coated drill bit will reduce the service life after grinding, how to avoid?

- Hello, there is no way to avoid the problem of reducing the service life of the carbide coated drill bit after grinding;Cemented carbide bit, in its use, the surface coating, the blade has already been damaged, can not reach the integrity of the factory, so that it affects the service life of the drill bit,There is a need to be re grinding, coating, the coating has physical and chemical coating and coating, coating chemical now use more chemical coating basically is the tool coating at high temperature, so the temperature can cause 2 damage of cemented carbide substrate;So it also affects the service life;The effect of bit life, the most important is the geometric design of drill bit; before the design is not good, but when re grinding and grinding a good point, sometimes improve the service life, but the original drill must use will reduce the life of the;About those problems mentioned above, in fact, that is, some methods to improve the service life of the drill, upstairs can refer to

- Q: What is the hardness of cemented carbide?

- Different grades, different hardness, usually (86 ~ 93HRA, equivalent to 69 ~ 81HRC);

- Q: How to tell what is hard alloy and what is high speed steel?

- Hard alloy can be drawn off on high speed steel, and vice versa

- Q: How to distinguish the authenticity of Zhuzhou diamond brand cemented carbide blade?

- In fact, now only look at the packaging has been unable to identify, because now the copycat alloy packaging has really not with what two things, want to know after the authenticity can be used, you can try to buy a small amount of alloy, the quality of clearance to buy a lot, you can go to the station to find the Alibaba China @ Rui Sen # trade. Easy% Co., reputation has been good, but sales of hard alloy Zhuzhou diamond factory, there are quality problems can return shipping.

- Q: Do you want to center hole? How deep is fit? Or do not hit it directly? My drill bit and the center hole contact point are easy to collapse

- A very shallow point can be;Because once too deep, and the center hole of the aperture is less than the drill bit to drill aperture, so is not in contact with the workpiece, but the main cutting edge part in contact with the workpiece, so cause drill can not correctly centering, so easy to collapse;In the deep hole processing, it is necessary to use pre hole; the general pre hole is the drill bit, the hole size is the same, and the depth is usually about 3 times;I hope I can help you

Send your message to us

RE FeSi For Casting Manufactural

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords