Raw Materials for Refractory:Sintered Spinel Al2O3 49-51 MgO 48-50

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shandong, China

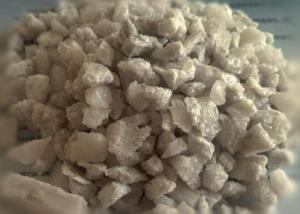

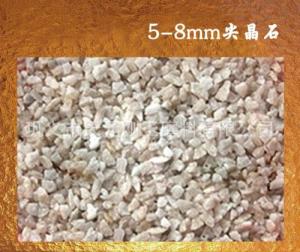

· Shape:particle or powder

· Material:Alumina

· Al2O3 Content (%): 46-51%

· Mgo Content (%): 48-50%

· Fe2O3:0.4%max

· SiO2Content (%): 0.35max

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Sintered spinel

· Color:White or shallow yellow

· Size:100MESH/200MESH/0-1MM/1-3MM/3-5MM/0-40MM or as customer's request

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:particle or powder or clinker

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have pictures?

A: Yes, please check the pictures:

- Q: Who know what kind of fire shutter fire rating are there?

- Fire resistance rating of the building elements is different due to the different requirements of the construction . Fire proof door can be divided into Serie A, B and C in terms of fire endurance limit, fire resisting limit are not should be less than 1.20h, 0.90h and 0.60h. That is, if the fire resistance rating is two, also it is possible to use a class a fire door. Hope my answer will help you.

- Q: what grades are fire resistance of fireproofing glass divided into?

- Fire resistance of fireproofing glass is generally divided into three levels, class A glass can satisfy the requirements of fire resistance and thermal insulation at the same time. Class B, it's a kind of fireproofing glass that can satisfy the requirements of fire resistance and heat radiation strength at the same time. Class C can satisfy the requirements of refractory integrity, if you want to know more specific requirements, you can also surf the internet for a more detailed description.

- Q: Can someone professionally introduce the classifications of refractories?

- It can be divided into two categories of ordinary and special refractory. Ordinary refractories can be devided into acidic, neutral and alkalinee refractories according to chemical properties. Special refractory can be devided into high temperature oxide, refractory compounds and high-temperature composite materials according to the compositions. Furthermore, it canbe devided into ordinary refractory products (1580 ~ 1770 ℃), advanced refractory products (1770 ~ 2000 ℃) and super refractory products (above 2000 ℃) according to the strength of refractoriness. It can be divided into bulks (standard brick, special-shaped brick, etc.), special shape (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia and boron carbide, etc.) and Indefinite shape (refractory clay, castableand ramming mass, etc.) according to the shapes of products. According to the sintering process, it can be divided into sintered products, cast products, melting jetting products.

- Q: How about the prospect of refractory material?

- Cost reduction Refractory material is affiliated to base material factories such as steel, cement and glass. But the situation becoms more severe due to lmaterial reduction and waste. It is necessary to find a substitutional raw material.

- Q: What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q: I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- What you said is the pixel! Only that has b1b2. Level b1 is the fireproofing level b1, because the particle does not belong to the fireproofing material. Only can fire?retardant. The wholesale of all kinds of thermal insulation material and construction need to look at the name.

- Q: How many refractory materials does the annual output of 1 million tons of coke oven require?

- Refractory materials are expensive, and any refractory accident will lead to a considerable waste of production time and equipment, and sometimes even the product itself. The type of refractory material will also affect energy consumption and product quality. Therefore, it is very important to select the refractory material which is most suitable for various applications. While the economic benefits have great influence, refractory material most suitable for some applications need not be used for materials, but can achieve a balance between material installation cost and performance, this balance is not fixed, but with the introduction of new technology or new refractory materials and changing. History has proved that unremittingly seek metallurgical process more reasonable and development, greatly promoted the development of refractories, quickly resolve these problems has become the modern refractory steel technology development is an important element. The content of this article is to discuss a number of factors including these issues and to provide information on how to solve them.

- Q: It the Special Fire-Proof Material belonged to ceramics? Is there a national standard of the Special Fire-Proof Material?

- The fiber and reinforcing material of the metal ceramic is also belonged to the Special Fire-Proof Material. ~~~~GB is too much trouble, GB online should ~~~ Lei Bao Refractories for you. The high temperature inorganic coating. 5. The refractory compound. 3. The high melting point oxide. You can search it on the internet according to the classification~~~~ The special refractories can be divided into five categories: 1. metal ceramic

- Q: How many external wall thermal insulation fireproof material are there

- Class A exterior wall insulation: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic foam, foam glass

- Q: What is the quote of fireproof and soundproof materials used in KTV?

- 1. fire retardant, sound absorbing sheet,eggs,pyramid,sound-absorbing material, piano room, studio, KTV, with glue on the rear, 15 Yuan 2. bar, KTV, fireproof sound insulation cotton, sound-absorbing materials, studio, eggs, drum practice room, sound-absorbing and sound insulation materials, pyramid, 25 Yuan 3. fireproof wood excelsior absorbent, sound absorbing board, wall ceiling decoration materials, materials, theater, KTV, wood color fiberboard, 30 Yuan.

Send your message to us

Raw Materials for Refractory:Sintered Spinel Al2O3 49-51 MgO 48-50

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords