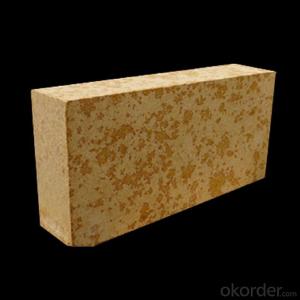

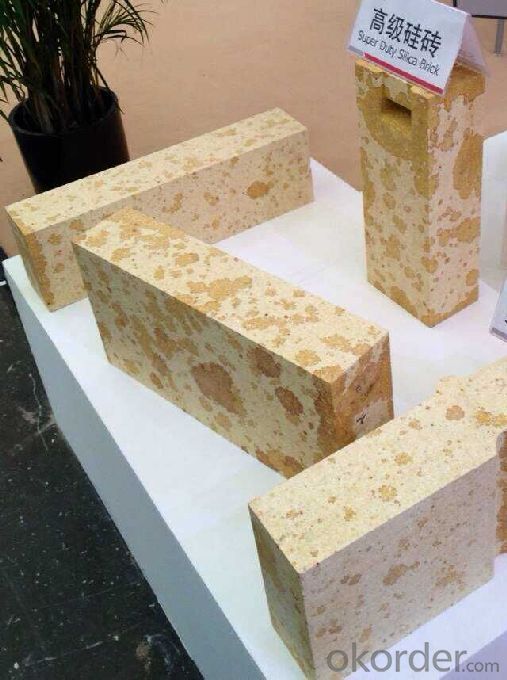

Raw Materials for Refractory Silicon Bricks Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information:

CMAX brand Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Features of Refractory silica bricks for Glass Kiln:

1. high volume density of 2.34 g/cm3

2. high SiO2 content of 96%

3. low iron content of 0.8%

4. low melting point of 5%

Applications of Refractory silica bricks for Glass Kiln:

Because of the high temperature resistant performance significantly, long service life characteristics (as long as more than eight years) of refractory silica brick for Glass Kiln, it can significantly improve the quality of glass, so the refractory silica bricks are widely used in all kinds of glass furnace melting department, regenerator and other important parts.

Physical and chemical index of refractory silica bricks for glass kiln:

Item Brand | CMAX-96A | CMAX-96B | ||

SiO2 % ≥ | 96 | 96 | ||

Al2O3+2(K2O+Na2O) % ≤ | 0.5 | |||

Fe2O3 % ≤ | 0.8 | 1 | ||

Refractoriness °C ≥ | 1710 | 1710.0 | ||

0.2MPa Refractoriness under load °C ≥ | 1680 | 1670 | ||

Apparent porosity % ≤ | Brick with weight no less than 20kg | 20 | 20 | |

rick with weight less than 20kg | 22 | 22 | ||

CS MPa ≥ | 35 | 35 | ||

Bulk desity g/cm3 ≤ | 2.34 | 2.34 | ||

Starndard Size:

230*114*64mm

230*114*76mm

- Q: What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is a material which has a strong impedance to the heat flow. the nature of the material requires that the material can isolate the delivery of thermal, and the low heat conductivity coefficient and expansion coefficient of the non-metal material.refractory is good in heat resisitance and chamical erosion but not high temperature resistance. Requirements on nature is still in high temperature.

- Q: I want to consult the fire resistant level standards of external wall thermal insulation materials.

- 1, The building with the height larger than or equal to 100m, should have the A-level combustion performance. 2, The thermal insulation material of the building, with a height larger than or equal 60m and less than 100m, should not be less than the level B2 combustion performance. When using the level B2 insulation material, each level should set horizonal fire barrier zone. 3, The thermal insulation material of the building, with a height larger than or equal to 24m and less than 100m, should not be less than the level B2 combustion performance. When using the level B2 insulation material, each two levels should set horizonal fire barrier zone. 4, The thermal insulation material of the building, with a height less than 24m, should not be less than the level B2 combustion performance. When using the level B2 insulation material, each three levels should set horizonal fire barrier zone. I hope my answer will help you. Thank you!

- Q: How to distinguish between class A fire resistant door and class B fire resistant door from appearance ? What are the differences between the two refractories? Thank you !

- From the perspective of appearances, grade A is 70mm, B 50mm. Their materials are the same .

- Q: Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q: The development prospect of fire-resistant material

- Luweishi (Furnace guardian)--- the wings ofrefractory material (blast furnace for high pressure grouting and liningmaking)--- is the fortune of furnace repair companies. Nowadays the sales of refractorymaterial are very difficult, but furnace repairing is popular. It does not onlyearn money but also sell refractory material, and even establish long-term,stable and interdependent business relations provided the price is acceptable.Many forward-looking companies such as Beijing Rongda, Anshan Yongheng, WuahnKehong, Shandong Zhangqiu, Gongyi Huaxi, Hongda, Zibo Xinfu and Anyang Tecai,allowing for the steel mills which are rich and try to do things the easy way, turnrefractory plant into or include into building company, resulting in greatsuccess in the bid invitation among so many units. Junwei can provide quality and efficient blast furnace equipment for grouting and lininLuweishi--- Luweishi (Furnace guardian) and research, design and manufacture as required. QQ:76350883

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- o

- Q: how is the high-temperature flame-retardant fibre board?

- Still good, we still can understand, we still feel good, I still can understand the amount of

- Q: I wanna ask what are the acidic refractories?

- Usually, acidic refractory refers to a kind of refractory which contains a amount of silicon?dioxide. There are the following: (1) silica?brick with stronge acidity, unshaped silicious refractory, quartz glass and fused silica combined products; (2) semi-silica refractory with moderate acidity and pyrophyllite refractory; (3) clay-based refractory with weak acidity. The main features of the acidic refractories is resistant to the erosion of acidic substances (acidic residue) in high temperature, but is easy to react with alkaline material (basic slag). zirconite fireproofing material and silicon carbide as the special acidic refractories refractories are also in this category.

- Q: What refractories can withstand high temperature above 2100 degrees?

- But the price is more expensive, while the insulation performance is not as good as common materials. Is there a material that can withstand 2100 ℃? Currently, the long-term use temperature of the best refractory bricks is about at 1800 ℃, while materilas that can withstand a temperature of 2100 ℃ are relatively rare in the production.

- Q: How to classify fire resistance rating of brick-concrete structure?

- In order to ensure the safety of the building, the fire protection measures must be taken to make it have a certain degree of fire resistance, even if there is a fire, it will not cause too much damage. According to the national conditions of our country, and in the light of other countries standards, < high-rise civil building fire protection design specification > defines fireproof rank of high-rise civil buildings into level one and two; < code for fire protection design of buildings > divides the rank into level one, two, three, four, level one is the highest level, level four is the lowest. Besides that the minimum fire resistance of the building component is specified, buildings of fire resistance rating also specified requirements for combustion performance. Because the component with the same fire resistance limit is different, it is different in the fire.According to our country national standard < building design fire protection code >, the fire resistance rating of the building is divided into four levels. The fire resistance of a building is determined by the combustion performance and fire resistance of building components (such as beams, columns, floors, walls, etc.). Generally speaking, the fire resistance building of level one is a mixed structure of reinforced concrete structure or a mixture of brick wall and steel concrete structure; the fire resistance building of level two is a mixed structure of steel truss structure, reinforced concrete column and brick wall; the fire resistance building of level three is brick-wood structure made of wood roof and brick wall; the fire resistance building of level four is combustible structure which is composed of wood roof and non-combustible wall.

Send your message to us

Raw Materials for Refractory Silicon Bricks Used in Glass Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords