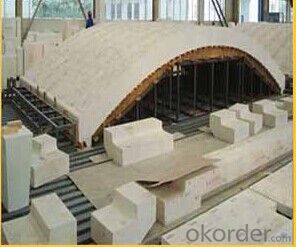

Raw Materials for Refractory Glass Furnace Superstructures Refractory Block

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1. Strong glass corrosion resistance and high thermal shack stability.

2. Good RUL, wear-resistance, dregs-resistance and alkali corrosion resistance.

3. The products are adopting superior material, with process by special arc furnace forming it. This fused cast technology got nearly no suffer from electrode pollution. They can be widely used in the lining of glass furnace, the chemical industrials, metallurgical furnace.

Our company can produce serious specification fused cast 33#, 36#, 41#AZS block for glass furnace and its output is over 5000tons per year. In the enormous working premises—more than 6600square meters, there are one 5tons outside cooling electric arc furnace, high-power transformer, thaw craft with computer control system and internal advanced fused cast refractory umeral control grinding equipments according to its body producing ability.

Erosion-resistance to glass metal

Physical and chemical index of Fused Cast AZS41# for glass furnace

Item | Behaviors | |||

AZS-33# ER 1681 | AZS-36# ER 1685 | AZS-41# ER 1711 | ||

Chemical Composition | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

SiO2 | ≤15.50 | ≤13.50 | ≤13.00 | |

Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

Bulk density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

Cold Crushing Strength Mpa | ≥300 | ≥300 | ≥300 | |

Exudation Temperature of Glass Phase | ≥1400 | ≥1400 | ≥1410 | |

Bubble Separation Ratio(1300°C×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

Anti-corrosion rate of glass liquid 1500°C×36h (mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

Apparent density (g/cm3) | PT(RN RC N) | ≥3.50 | ≥3.50 | ≥3.70 |

ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.70 | ≥3.90 | |

WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.8 | ≥4.00 | |

1.High purity

Good self-sharpening

Grinding ability

Resistance to acid and alkali corrosion, high temperature thermal stability is good

- Q: Do you know what the main indicators are for the inspection of refractory materials? Thank you very much for your requests and reports

- Porosity, volume density, water absorption, true density, thermal expansion, thermal conductivity and heat capacity.

- Q: Can quantitative feeder be used in refractory plant? Thank you

- Feeder experts, justice and analysis, quantitative feeder, of course, can be used in refractory plants

- Q: How to choose thermal insulation materials for flood heating?

- 1, Select the appropriate floor material suitable for radiant floor heating. The floor radiant heating system mainly transfer heat through the ground concrete and the ground material to the room. Therefore in the heating season the ground material will always be heated during heating season. Therefore, it is better to choose stone materials and compround floor plate insensitive to tenmperature change with good heat dissipation and functions. Currently, wood floor is not suitable for the ground radiant heating system. 2, choose the pipe with anti permeability performance. Plastic floor heating pipe itself has a certain air permeability, if oxygen penetrates in it is prone to oxygen erosion and system's mental device will be eroded, resulting in the risk of leakage. Therefore in order to ensure the reliable operation of the heating system, the selected pipe must have anti oxygen permeation performance, and meet the standard stipulated by the DIN4726 oxygen permeation quantity: and be less than 0.1mg\L.d at 40 C.

- Q: Is there requirement for radiation indicator in refractory?

- All refractories have no radiated harm to environment, so there is no requirement. From the elemental analysis, magnesite. I do not know it is helpful to you. But for refractory rwa material, any chemical element is radiated, including silicon?dioxide; If they are radioactive. From the use analysis, such as bauxite, do not have use value.

- Q: Who knows about the criteria of fireproof and thermal insulation materials?

- Seven levels are divided according to "The classification of combustion performance of building materials and products", namely, A1, A2, B, C, D, E, F. It mainly refers to the combustion performance of materials. You can check on this standard for the specific dividing evidence. There are detail charts which mainly describe that whether there is drip or not, the ignition time, continuous burning time and so on.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: What are the technical requirements for refractories?

- The range of refractory is too broad. Therefore it is difficult to answer this question, but it is certain that there should be technical requirements.

- Q: Who knows the texture of fire-proof wooden door material?

- The so-called fire doors are only posted a layer of fireproof material. Door selection still depends on the timber inside. The simplest way is to see the weight value, fireproof material layer, and they are generally paint-free doors. With fireproofing function.. Hope you adopt.

- Q: Who can tell me the properties and classification of insulating refractories?

- The refractory materials refers to the refractory material of high porosity, low volume density, low thermal conductivity of the insulating material. Also called lightweight refractories. It includes insulating refractory products, refractory fiber and refractory fiber products.The characteristics of insulating refractory material is of high porosity, generally 40% to 85%; the volume density is low, generally less than 1.5g/cm3; the thermal conductivity is low, generally less than 1.0W (M - K). It is used as the insulation material of industrial furnace, furnace can reduce heat loss, save energy, and reduce thermal insulation equipment weight. The mechanical strength of refractory material, abrasion resistance and slag resistance is poor, should not be used for load-bearing structure of furnace slag, furnace, and direct contact with the molten metal and other parts.

Send your message to us

Raw Materials for Refractory Glass Furnace Superstructures Refractory Block

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords