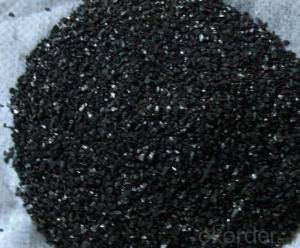

NATURAL FLAKE GRAPHITE Refractory Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Provide various packing options according to customer requirements. |

| Delivery Detail: | 10-60 days according to order |

Specifications

1.Fixed Carbon 94%-99%

2.50, 80,100, 120,150,200,325 mesh

3.High purity flakes graphite

4.24 years experience

Natural Flakes Graphite Series

Advantage:

Perfect crystallization, great size in flake, high density, low content of mica, high luminance, excellent physical properties, such as resistance to high temperature, electric and thermal conductivity, self lubricity, and superior chemical stability

Size:

Adjustable to meet customer requirements, and major sizes include 50, 80,100, 120,150,200,325 mesh

Packing:

Provide various packing options according to customer requirements. Including Woven Bags, Paper Bags and Plastic Bags of 25KG, 50 KG, and 1000KG.

Technical Specification For Medium Carbon Graphite | |||||

Brand No. | Specification | ||||

Fixed Carbon (≥%) | Volatile (≤%) | Ash (≤%) | Moisture (≤%) | Remains on Sieve (%) | |

LG50-94 LG80-94 LG100-94 LG120-94 LG150-94 | 94 | 1.2 | 4.80 | 0.50 | ≥80.00 |

LG(-)100-94 LG(-)200-94 LG(-)325-94 LG(-)500-94 | ≤20.00 | ||||

LG50-95 LG80-95 LG100-95 LG120-95 LG150-95 | 95 | 1.2

| 3.80 | 0.50 | ≥80.00 |

LG(-)100-83 LG(-)200-83 LG(-)325-83 LG(-)500-83 | ≤20.00 | ||||

LG50-96 LG80-96 LG100-96 LG120-96 LG150-96 | 96 | 1.2 | 2.80 | 0.50 | ≥80.00 |

LG(-)100-96 LG(-)200-96 LG(-)325-96 LG(-)500-96 | ≤20.00 | ||||

LG50-97 LG80-97 LG100-97 LG120-97 LG150-97 | 97 | 1.20 | 1.80 | 0.50 | ≥80.00 |

LG(-)100-97 LG(-)200-97 LG(-)325-97 LG(-)500-97 | ≤20.00 | ||||

LG50-98 LG80-98 LG100-98 LG120-98 LG150-98 | 98 | 1.00 | 1.00 | 0.50 | ≥80.00 |

LG(-)100-98 LG(-)200-98 LG(-)325-98 LG(-)500-98 | ≤20.00 | ||||

LG50-99 LG80-99 LG100-99 LG120-99 LG150-99 | 99 | 0.70 | 0.30 | 0.50 | ≥80.00 |

LG(-)100-99 LG(-)200-99 LG(-)325-99 LG(-)500-99 | ≤20.00 | ||||

- Q: Why just renovated the house put a plant, activated carbon, bamboo charcoal, the taste is still great

- These plants, Chlorophytum Sansevieria Ivy aloe agave gerbera.3, activated carbon adsorption method.With the adsorption of activated carbon, bamboo charcoal to remove these harmful gases, is currently the most widely used method. But there is a determination that the role of activated carbon space is small, large space to use the amount of activated carbon is also relatively large.

- Q: How to make charcoal war of survival

- 5, and then you can see the list of items.First of all, you can use logs to burn leaves can be obtained, followed by the excavation of the rock layer. Generally in the underground 10*10 can find coal. Coal is used to dig or burn wood into charcoal.

- Q: What is the difference between activated carbon and charcoal?

- Activated carbon is a kind of porous carbon, according to the adsorption characteristics of activated carbon, activated carbon is mainly used to remove pollutants in water, decolorization, filtration and purification of liquid, gas

- Q: Bamboo charcoal package to how long exposure

- Because, after the use of bamboo charcoal package for a period of time, harmful substances attached to the surface of bamboo charcoal or blocked in the hole crossing, will affect the adsorption of bamboo charcoal on other harmful substances. After drying in the sun, the role of ultraviolet light, some of the microbes will be killed, roadblocks were cleared. Once again, the adsorption effect will be better.

- Q: What is the difference between how to distinguish

- If it is barbecue: the guests to bake their own, it is best not to use the charcoal fire (apple wood charcoal), to prevent the burn out of the clothes of the guests.

- Q: Why is heating charcoal poisoning??

- If you close the doors and windows of charcoal heating, indoor oxygen shortage, charcoal will continue to burn, but the incomplete combustion produces a large amount of carbon monoxide. Carbon monoxide was inhaled into the body, so that the loss of the ability of red blood cells to transport oxygen, causing tissue hypoxia, resulting in a variety of toxic symptoms

- Q: The difference between raw coal and fuel coal

- It burned after no tobacco ~ how professional. I study chemistry.

- Q: On behalf of the company to study the coal test, which can help me to explain the online test of coal each indicator of the process, thank you

- (2) the external and internal moisture of coalThe free water of coal is divided into external and internal water.External moisture, which is attached to the surface of coal particles. The external water is easy to evaporate in the dry air at the normal temperature, and the vapor pressure which evaporates to the surface of the coal particles does not evaporate when the air pressure is balanced with the air.Internal moisture, which is adsorbed in the pores of the coal particles. The temperature of the internal water needs to be above 100C to evaporate after a certain time.

- Q: How is the charcoal burning out

- The trees cut into sections, lit in a kiln, burning to a certain extent, closed air into the kiln, waste heat to heat water and carbonization of wood, wood tar is leavened, carbonization of wood charcoal as. This is similar to the past when the family of firewood burning charcoal.Now there is the use of wood chips and other waste processing mechanism of charcoal, the waste pressing forming, indirect heating in the furnace for carbonization, these raw materials carbonized into charcoal.The quality of charcoal can only be used according to different quality indicators. Usually, we measure the quality of the charcoal mainly from the moisture content, volatile fraction, ash content, fixed carbon content and calorific value

- Q: Coal formation process and time

- The thickness of coal seam in a coal mine and the crust drop speed and accumulation amount of plant remains. The crust decreased rapidly, the plant remains piled thick, the coal seam is thick, on the other hand, the crust decline slowly, the accumulation of plant remains thin, the mine coal seam is thin. The tectonic movement of the crust to the original level of coal seam folds and faults occur, some underground coal seam buried deeper, and squeezed to the surface, even above the ground, more likely to be found. There are some relatively thin coal seam, and the area is not large, so there is no value related to the formation of coal mining, so far not find the update statement.

Send your message to us

NATURAL FLAKE GRAPHITE Refractory Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords