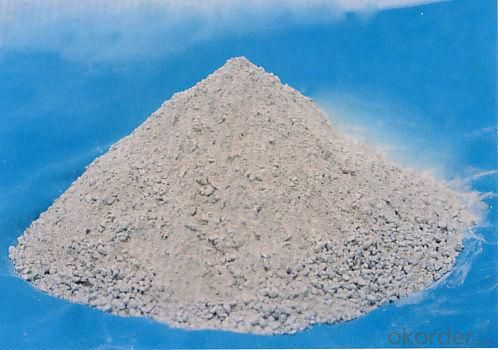

Raw Materials for Refractory:Cement Refractory Cement / High Alumina Cement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Corumdum mullite series castable refractory cement for Petrolchemical&Coal Chemical Industry

Corundum mullite series castables features:

1. high refractoriness

2. good chemical stability

3. high strength

1. The corundum mullite series castables, prepared with tabular alumina, white fused alumina, fused mullite, etc. as starting materials, are characterized by high refractoriness, good chemical stability, high strength, etc.. The castables with Al2O3≥94% are corumdum castables.

2. The castables are mainly used for on-site casting and off-site precasting for working linings of high temperature refining chemical equipment in chemical and metallurgical industry.

Technical Data

| Item | Corumdum mullite series castable refractory cement for Petrolchemical&Coal Chemical Industry | ||

| Corundum mullite castables | Corundum castables | ||

| CastPA72 | CastPA88 | CastPA94 | |

| Long term service temperature,℃ | 1550 | 1600 | 1650 |

| Al2O3,% | 72 | 88 | 94 |

| SiO2,% | -- | -- | 0.5 |

| Fe2O3,% | 0.5 | 0.5 | 0.3 |

| Bulk density,g/cm3(110℃×24h) | 2.5 | 2.7 | 2.9 |

| CCS,MPa (110℃×24h) | 50 | 50 | 55 |

| Linear change rate after heating,% ,(1300℃×3h) | ±0.4 | ±0.3 | ±0.3 |

Packaging & Shipping

| Packaging Details: | 25kg or 50kg per small bag or as customer's demand |

|---|---|

| Delivery Detail: | After 7 days with stock, 30 days production and inspection |

Our Services

♥ Research of application basis, new technical process and new technology, development of new product, and technical consultation.

♥ Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

♥ Engineering design, contract and consult for refractories, and civil architecture design.

♥ Research,development, manufacture and sale of superhard materials.

♥ R&D, manufacture and sale of special packing materials for export.

♥ Inspection,supervision and arbitration of refractories.

♥ Consultation and services in refractories information.

♥ Training and cultivation of high-level talents in refractories profession.

- Q: What is the importance of silicon powder in refractory processing?

- it depends on the type of refractory material, in addition to lS friends talked about, in the amorphous mobility\ strength should also have an impact

- Q: Who knows what is the external wall thermal insulation materials for level A fireproofing?

- external wall thermal insulation materials level A fireproofing: Incombustible building material is a material that does not occur any burning. Class A1: Monomer inorganic non-combustible. Noncombustible means no open fire. Class A2: Non-flammable organic compound is namely composite materials and non-flammable, the amount of smoke must be qualified. Class B1: nonflammable building material: non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Class B2: combustible?building?materials: flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs.

- Q: What kinds of refractory will be used in kiln of sintering ceramics?

- Porcelain has many classes, including acid, alkaline and neutral materials.

- Q: what are the requirements of fireproofing material?

- The producing process of fire and moth proof wood: firstly, put general wooden materials into solution with calcium, aluminum and other cations, then soak it into the solution with phosphate radical, silicate and other anions. Thus, the two ions will be carried out chemical reaction in the wood, forming a ceramic-like material, and intimately fill the voids of cells, so that the wood has the fireproofing and mothproof properties.

- Q: Who knows the fire resistant level of the rock wool color plate?

- Hello; Same with other unprotected steel, the fire endurance of the color steel?plate is generally 15 minutes. It is not a fireproofing material, let alone fire resistant level. If the color steel plate has sprayed fire retardant coating and the thermal insulation filling material in the core is rock wool fiber, it can achieve A level fireproofing requirements. The color steel?plate refers to the painted steel plate, which is a steel plate with organic coating. The color steel board is divided into the single plate, color steel composite board, floor support board, ect. It is widely used in large public buildings, public plants, portable dwelling, and integrated housing walls and roofings. I hope that will help you.

- Q: What are the insulation fireproofing materials?

- Insulated shoes, insulated gloves, tape (cloth, plastic, as well as waterproof) yellow wax tube, mouth care, fireproof (ie asbestos cloth is sold by jin) there is pressure-caps black tape, waterproof tape ,casing. There are glass fiber needle felt is widely used in electrical, chemical, construction, transportation, automotive and other industries interlayer insulation and silencer system, and used as an insulating fireproof material.

- Q: What things and cement mixed can act as refractory?

- This has a lot. I suggest you can check monolithic refractories.

- Q: What are the differences between first-level fire-resistant materials and second-level fire-resistant materials?

- The combustion performance of materials could be divided into: A( noninflammability), B1(flame retardancy), B2(flammability), B3(inflammability). Building materials are divided into four ranks according to these properties. 1. In accordance with Code for Design of Building Fire Protection(GBJ16-1987)(revised edition in 2001), fire hazards in producing and storage can be divided into five types. In Fire Prevention Code of Petrol Chemical Enterprise Design(GB50160--1992)(revised edition in 1999), classification of fire hazards is also achieved according to the hazards of materials that have been using, producing and storing. Measures in prevention of fire explosion could be taken from the perspectives of fire separation, fire resistance level of structures, allowable floors, safe evacuation, and fire extinguishing facilities based on different levels of fire hazards. 2. Four fire resistance rating of buildings are listed in the book Code for Design of Building Fire Protection. And specific stipulations are made to the fire resistance of main elements of buildings, such as bearing walls, beams,pillars, and floors. When designing a building, if permitted, refractory materials of high-rank should be adopted in those buildings which have high potential fire hazard and a lot of combustible material and valuable equipment. While making sure fire resistance rating, the duration of fire resistance of each elements should meet its requirements.

- Q: Who knows about the B-level fireproof insulation materials?

- Organics, extruded sheet, polyphenyl board and phenolic resin. The fireproof?performance of sea capacity module (fireproof and thermal insulation material) is B1-level with the heat conductivity coefficient of only 0.028w / m · k. It is a good choice. A-level: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic aldehyde, and foam glass. B-level: Rubber and plastic, extrusion molding, polyphenyl, PEF.

Send your message to us

Raw Materials for Refractory:Cement Refractory Cement / High Alumina Cement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords