Raw Materials for Refractory:Calcined Bauxite Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Grade Calcined Bauxite Powder

Calcined Bauxite Introduction

Property | Specifications |

Name | aluminous soil ; bauxite |

Color | White, offwhite, auburnish yellow or light red (with Fe) |

Bulk Density | 2.55~3.6 g/cm3 |

Hardness | 1~3 |

Main usages | 1. Aluminium metallurgy 2.Refractory |

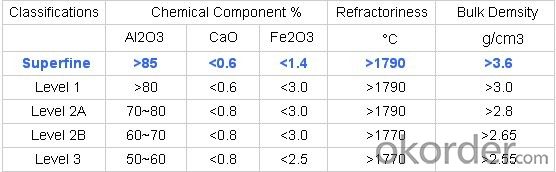

Calcined Bauxite Specifications

Calcined Bauxite Applications

1. Aluminium metallurgy

2. Precision casting / Investment casting:

bauxite grog fines can be made into mold for precision casting.

3. Refractory: high alumina bauxite’s refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance. (Al2O3 ≥48% with low Fe2O3)

4. Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under 2000°C-2200°C in the electric arc furnace.After a series of processing, it can become aluminium silicate refractory fiber,

which can be made into fiber blanket, plate,cloth.

5. Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining

performance.

6. Producing bauxite cement

7. Abrasives

8. Ceramics industry

9. Chemistry industry for all kinds of aluminium compound.

Pictures:

- Q: what's the application of fireproofing abs materials?

- a kind of ABS alloy shell, a toy of child, low load bearing, refrigerator lining, it can be processed into various wear-resisting sheets, plates,and has good electrical performance, it can be used as electronic components or auto parts, all kinds of insulation materials, it's easy to machining on the surface, so it can be made into designated special products (such as electroplate), and easy coloring, it can be processed into colorful products, also can be used as a fireproofing electrical appliance outer covering, adding alloy to it will improve its comprehensive performance, etc

- Q: What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- Fire endurance (h): Under the condition of standard fire resistance test, the time when the building components, accessories, or structure is subjected to fire to the time when they loose stability, integrality or thermal insulation is called fire endurance which is showed in time. Steel is the kind of building material that is nonflammable with many properties of seismic resistance and bending resistance. In practical applications, steel can improve the load capacity of buildings in a relative way, meet the needs of buildings design, beauty and mould, and it can also avoid the defects of poor flexibility and tensile strength of buliding materials like concrete. Therefore, steel is quite popular in the construction industry, and it is widely used in single-story or multi-storey skyscrapers, plants, warehouses, waiting rooms and airport terminals, etc. However, as a kind of building material, it has some unavoidable defects in fire prevention. That is its mechanical properties like yield point, tensil strength and elasticity modulus will decrease dramatically with the rise of the temperature.

- Q: How much is the duration of fire resistance of the porous brick shale?

- The duration of fire resistance of the porous brick shale could reach 1,580℃—1,770℃. It is predominantly applied in coke oven masonry and building, glasses, porcelains, carbon calciner, and the vault of thermal furnuces of refractory bricks as well as other load-bearing elements, and high temperature bearing parts of cowper stove. But it should be aware that it can’t be used in thermal equipment below 600℃ and with large variation of temperature.

- Q: Which kind of furnace hearth refractory is better?

- hearth selected material] hearth material must be durable, high temperature resistant, general selecting masnory made of refractory cement, silicon carbide refractory products, mullite or multicrystal mullite (which is the general term of minerals composed of a series of aluminum silicate, mullite is only stable binary compound in the Al2O3-SiO2 system) etc.. [hearth] is a three-dimensional space surrounded by furnace walls for combustion of the fuel. The funtion of hearth is to ensure the fuel to burn as far as possible, and to cool the gas temperature of the hearth exit to the allowed temperature of convection heating surface safe operation . Therefore, the hearth should have sufficient space and adequate heating surface. In addition, there should be reasonable shape and size in order to fit the burner and the organize aerodynamic field inside the furnace to prevent the flame from adherence, dashing walls and have high fullness and eve wall thermal load.

- Q: What is the acceptance standard of refractory?

- It depends on the variety of materials. In general the main test items include chemical composition, refractoriness, refractoriness under load, creep, volume density, linear change, strength, slag resistance, thermal conductivity and thermal expansion. If it is shaped products, it is required to inspect the size deviation and whether it has edge. Detection method accords with the relevant national standards and there are lots of them. You can refer to the standard compilation.

- Q: how to classify the fireproofing material levels A1 A2 B1?

- their classification is shown specifically in Fireproof? Specification of Building Interior Decoration?Design GB 50222-95 appendix A, flammability,inflammability materials, flame retardency, noninflammability: combustion performance of A, B3, B2, B1 materials are divided into

- Q: Who can tell me the properties and classification of insulating refractories?

- It is the chemical method. The chemical reaction in the brick making process to produce gas and method for obtaining a porous brick. Usually use chemical reactions such as carbonate and acid, metal powder with acid, caustic and aluminum. Chemical reactions can be used must be relatively slow and can control or mechanical disturbance will disappear bubble in an injection mold. If the reaction is too fast, adding inhibitors such as hydrogen peroxide and manganese dioxide. The fine powder material slurry mixed with reactant bubbles to obtain stable foam slurry injection model, after drying the firing. This method of making pure oxide insulating refractory products, its porosity can reach 55% ~ 75%.

- Q: Are the rubber insulation materials are refractory materials?

- No

- Q: what is steel fire door made of ?

- 1. fire resistance steel door has steel made door frames, door leaf framework and door panels. if the door leaf is filled with nontoxic fire insulation material, added with fireproof hardware accessories, which consists of a door that is fire resistance. 2. Category 1)safety facilities to prevent underground building from fire expansion and control volatilation. It is usually divided into steel and wooden fire door. 2) Class A fire doors, fire endurance of 1.5 hours; B fire doors, fire endurance of 1.0 hours; Class C fire doors, fire endurance of 0.5 hours. 3) In fact, there are many types of fire doors. For example, there are wooden made fire doors glass fire doors and steel fire doors based on different materials. access control fire doors, entrance fire resistance door, interior fire doors, explosionproof and fireproof door, quick-lock fireproof doors, quick opening door encountered with fire and multi-functional fire doors. 4) Based on the installation location: External fire doors and built-in fire doors. 5) divided by technology: Electronic fire doors.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite Powder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords