Raw Materials for Refractory:87% Shaft Kiln Calcined Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

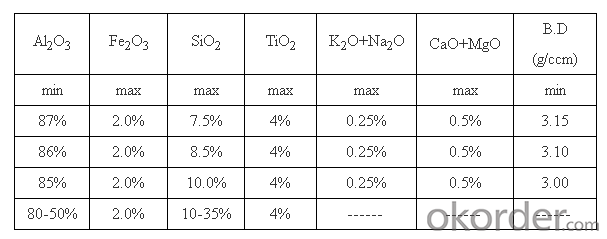

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Powder | Material: | Raw Bauxite |

| SiO2 Content (%): | 7.5%-35% | Al2O3 Content (%): | Al203:85%,86%87% | Model Number: | ZYD1511 |

| Brand Name: | cnbm | color: | pale yellow and dark grey | CaO+MgO: | 0.5Max |

| size: | natural lamp, 0-100/0-50/0-25 mm;0-1/1-3/5-8 mm | B.D.(g/ccm): | 3.10-3.15 | TIO2: | 4%MAX |

| FE2O3: | 2%MAX |

Packaging & Delivery

| Packaging Details: | IN BULK 1.25MT BIG BAG OR BY BUYERS REQUIREMENT |

| Delivery Detail: | 15-20DAYS |

Shaft Kiln Kalcined Bauxite

Product Description

Factory overviews

Laboratory

Packaging & Shipping

Our services

Give an answer within 24 hours;

Offer competitive prices;

Provide various certificates according to client’s requirements;

Provide sample freely;

If needed, we are able to travel with customer to visit our factories;

Satisfy the client’s needs to the maximum.

Advantages

We are an experienced Bauxite manufacturer with a decades-year long history;

The majority of our material are from Shanxi, a place known as the home of bauxite, so we are sure that the quality of product we supplied is very high;

We have both advanced machine and skilled workers in our factory;

In the term of material transportation, we have the professional export team;

What is worth mentioning is that we enjoy a good reputation around the world and we have many regular customers every year.

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- I do not recognize all the answers. No matter what kind of refractory can be used in construction. Biulding syove or kiln is construction. So personally, it belongs to construction indusrty.

- Q: How long is the duration of fire resistance of hollow glass magnesium board

- Hollow glass magnesium board features fire prevention, waterproof, tasteless, non-toxic, not frozen, not rot, not crack, unchanged, non burning, high strength and light weight, convenient construction, long service life and so on, and it has more characteristics among products of the same kind nationwide. Its fire resistance limit is 0.65℃.

- Q: What kind of material is refractory fiber?

- Refractory fiber, also known as ceramic fiber, is a fibrous thermal insulation refractory. It has the characteristics of ordinary fibers, such as softness, flexibility, having a certain tensile strength. And it can be further processed into a variety of products such as paper, wire, rope, tape, blankets and felts. Besides, it has high temperature resistance and corrosion resistance which ordinary fibers don't have. As a fire retardant and thermal insulated material, it has been widely used in metallurgy, chemical, machinery, building materials, shipbuilding, aviation, aerospace and other industrial sectors.

- Q: What is the use of refractory?

- Some is insulated for personnel safety, some is to save heat loss and conserve energy, and some is used as lining of kilns. Because of its light weight, I recommand it to you and I am engeged in ceramic fiber, just an advertisement.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- Sintered shaly hollow bricks of Chu area have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance. The fire endurance of sintered shaly hollow bricks should not exceed1050 degrees otherwise they will burn excessively. I, actually, think that the temperature should be controlled within 980 degrees. I hope my answer may help you.

- Q: Which are fire proofing thermal insulation materials?

- aluminum silicate fiber, ceramic fiber, etc,

- Q: What's the B grade fireproofing material?

- Grade B: rubber and plastic, extrusion molding, polyphenyl, PEF. organics, extruded sheet, polyphenyl board, phenolic resin. Hairong modules (thermal insulating and fireproof material) can reach grade B1 in fireproof performance.

- Q: What are the common refractory insulation cotton material?

- High aluminum, clay brick, aluminum silicate fiber module and so on, inorganic types are glass wool, rock wool, foam glass etc.. Organic: the best one is phenolic foam, compround phenolic foam cement layer is a-level. Aerated concrete and other refractory thermal insulation material mainly refers to the inorganic thermal insulation materials and compround thermal insulation material, expanded perlite, foam clay It is applicable for buildings that have high requirement for fire proof level, foamed concrete, volcanic ash glass.

- Q: On the problem of making refractory materials

- But if only a is chosen, does it mean that as long as it is insoluble in water, it can be made of refractory material? Obviously absurd!

- Q: Which fireproofing materials factory is the best in Xiangyang?

- Of course, it is "Lvchuang Construction Energy Saving Engineering Co., Ltd." in Xuzhou, which main products are A-level fireproofing thermal insulation boards. It has many projects. B1-level fireproof materials are polyphenyl boards, extruded sheets, phenolic foam boards, Polyurethane board, sea capacity building energy efficiency module. Flame retardant has been added to the sea capacity building energy efficiency modules which has a B1-level fireproofing performance. You can also add expanded glazed hollow beads to them if you are worried about the security.

Send your message to us

Raw Materials for Refractory:87% Shaft Kiln Calcined Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords