Raw Materials for Refractory:86% Alumina 60 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

86% Alumina 60 Mesh Calcined Bauxite with Low Price

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

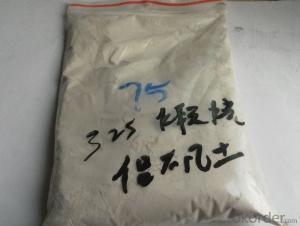

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: How long is the fire-fighting time of A class fire resisting window?

- Fire resisting window' duration of fire resistance: A class window, fire insulation ≥1.50h and fire resistance integrity ≥1.50h. Fire resisting window can be divided into three kinds: 一. window frame and sash framework adopt fire resisting window with steel manufacture ; 二. window frame and sash framework adopt fire resisting window with wooden manufacture; 三. window frame adopt steel and sash adopt wooden material or window frame adopt wooden material and sash framework adopt fire resisting window with steel material.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Strictly speaking, as long as there are solid wood packaging, you need to do fumigation inspection, proved not necessarily used, there are IPPC chapters on it.

- Q: which kind of refractory is used in golden smelting furnace? How about his using temperature

- generally the price of the quartz sand refractory material is higher and the temperature can meet the requirement of 2000 degree.

- Q: what are the requirements of fireproofing material?

- answer: 1 fireproof materials are used in construction, in various forms and it has played an absolute role in modern fireproofing, common fireproofing materials include fireproof?panel, fire door, fireproofing glass, fire?retardant?coating, fireproof bag,etc. 2, fireproof?panel is the most common texture in the market. There are two common types: One is the high pressure decorating refractory slab, it's advantages are fireproofing,moisture-proof, wear-resistant, oil resistant, easy to clean, and it has various colors; another one is glass magnesium fireproof board, external layer is decoration materials, and inner layer is mineral magnesium fireproofing material, and it can endure 1500 degrees high temperature but has bad decoration. Installing fireproof suspended?ceiling in outlet channel of construction, stairwell and corridor can ensure safe evacuation of people and protect people from attacking of fire spreading in the disaster. 3, the production process of fire and moth proof wood: firstly, put general wooden materials into solution with calcium, aluminum and other cations, then soak it into solution with phosphate radical, silicate and other anions. Thus, the two ions will be carried out chemical reaction in the wood, forming a ceramic-like material, and intimately fill the voids of cells, so that the wood has the fireproofing and mothproof properties.

- Q: What's the classification of flameproof glass, the refractory time of fireproofing glass.

- According to different manufacturing technique, thermal insulation fire-resistant glass can be divided into grouting fireproof glass and composite fireproofing glass. Grouting fireproof glass has good thermal insulation performance, composite fireproofing glass has good fireproof?performance.

- Q: What is the the best matching ratio of refractory cement?

- The best matching ratio of refractory cement is 30%. Refractory cement is also known as aluminate cement. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement. Aluminate cement is often yellow or brown or gray. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc. It is a special cement. I hope my answer will be helpful to you.

- Q: How to make the service life of refractory materials longer?

- Take acid resistant refractory materials as example: the atmosphere should be acidic atmosphere, if used in an environment whose temperature is 1900℃, it would exacerbate the loss of refractory materials, so don’t use overloaded. Second, select the appropriate refractory materials according to the environment. For example, if its operating temperature is 1800℃, generally speaking, the normal use of it according to the instruction of refractory materials would be fine.

- Q: Could you tell me how does fire protection standard of decorative material is divided?

- Level of fire prevention materials: A grade: non-combustibility building material, almost without burning materials. A1 level: non-combustible, no flame A2, non-combustible, to measure smoke, to be qualified. B1 level: flame retardant building materials: flame retardant materials has good flame retardant effect. It is uneasy to burn when encountering open fire in the air or under high temperature and is not easy to quickly spread, and when the fire source move, it will stop burning immediately. B2 level: combustibility building materials: combustibility materials has good flame retardant effect. It will immediately burst into flames when encountering open fire in the air or under high temperature. It easily leads to the spread of fire, such as timber, wooden frame, wooden beams and wooden stairs. B3 level: flammable building materials, without any flame retardant effect, easy to burn, and with a very high fire risk.

- Q: Which fireproofing materials factory is the best in Xiangyang?

- Xiangyang Tianhua Fireproof Materials Co., Ltd. has a variety of products with complete specifications. The products include fireproof cable tray, fire resistant groove, fire-resistant shield, ATD-AB, organic fire-proof caulking, intumescent fireproof pillow, fire retardant module, cable refractory coating, ultra-thin fireproof coatings for steel structure and other products. All products have passed the relevant tests and inspections, all performance indexes are in full compliance with national or industrial standards, and meet the technical requirements of cable fireproofing. Xiangyang Weicheng Fireproof Materials Co., Ltd. is specialized in research and development of fire-fighting apparatus and fire retardant materials! It's main products: fireproof bag, asbeston, fireproofing mud, and other types of fireproofing materials.

- Q: About the use of horseshoe glass kiln refractories

- the lower portion of advanced clay brick, the lower portion of magnesia-chrome brick arch - high-purity silica brick; flue - clay brick; breast wall--33 # fused zirconia corundum brick (with shrinkage); fused zirconia bottom --33 # fused zirconia corundum brick (with shrinkage); regenerative chamber- the upper part of sintered magnesia-chrome brick, cooling section 33 # electric?smelting no shrinkage fused zirconia corundum brick; the wall - the melting section 41 # no shrinkage fused zirconia corundum brick (including 41% of zirconium; the lattice- superstructure of high purity magnesia brick, the same below); small stove --33 # fused zirconia corundum brick (with shrinkage). It can be said that it is the maximum configuration, if the funds is limited it can be downshift appropriately.

Send your message to us

Raw Materials for Refractory:86% Alumina 60 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords