Raw Materials for Refractory:70% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

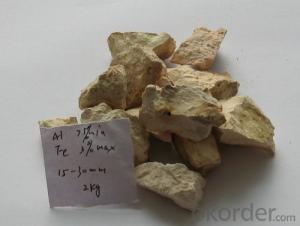

70% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Calcined Bauxite

1. Calcined bauxite

AL2O3:70% min.

FE2O3:2% max.

SIZE: 1-5MM 90% min.

2. Round kiln bauxite

Al2o3: 80-90% min.

Fe2o3: 1.5-2.0% max.

B.D.: 3.10g/cm-3.35g/cm min.

3. Shaft kiln bauxite

Al2o3: 80-85% min.

Fe2o3: 1.5-2.0% max.

B.D.: 3.10g/cm-3.25g/cm min.

4. Rotary kiln bauxite

Al2o3: 80-90% min.

Fe2o3: 1.5-2.0% max.

B.D.: 3.10g/cm-3.35g/cm min.

Size of 70% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description of 70% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Application of 70% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material:

1.Aluminium metallurgy.

2.Precision casting/Investment casting: bauxite grog fines can be made into mold for precision casting.

3.Refractory: high alumina bauxite's refractoriness can reach 1780°C.

It is charactered by good chemical stability and mechanical performance.(Al2O3 ≥48% with low Fe2O3)

4.Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under2000°C-2200°C in the electric arc furnace. After a series of processing, it can become aluminium silicate refractory fiber, which can be made into fiber blanket,plate,cloth.

5.Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining performance.

6.Producing bauxite cement.

7.Abrasives.

8.Ceramics industry.

9.Chemistry industry for all kinds of aluminium compound.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What's the fire?retardant material of roller shutter fire resistance door ?

- Core board of fire door materials are composited by inorganic materials, and the main components are perlite, inorganic adhesive and other special formula. It has flat and smooth surface, unibody. It is fireproof, sound and thermal insulating. It has passed tests of Tianjin Fire Research Institute and Beijing construction institute.

- Q: How to detect the acid resistance of refractory? Is there any standard? Thank you

- Setting the acid resistancere of fractory products is simple; R22, two measurement methods are both bricking refractory products, using the mass fraction of the original dry to indicate. It is generally select vitriol as the medium of erosion, such as the international standard determination of the resistance to sulfate of dense shaped refractory products "(ISO8890) and PRE /, grinding fine particles to 0.63 ~ 0.80 mm, and then measure its quality loss, put it in the vitriol with mass fraction of 70%, finally boil 6 h.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- Sintered shaly hollow bricks of Chu area have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance. The fire endurance of sintered shaly hollow bricks should not exceed1050 degrees otherwise they will burn excessively. I, actually, think that the temperature should be controlled within 980 degrees. I hope my answer may help you.

- Q: What dose the fireproof and thermal insulation material include?

- Currently the non-combustible insulation materials for external insulation system mainly are foam insulation board, composite cement foam insulation board, aerated concrete panels, rock wool board (strip), and inorganic insulation materials. 1. foam insulation board refers to foam ceramic insulation panels whose raw material is inorganic ceramic which is calcinated at high temperature with abbreviation of ceramic insulation board 2.Composite cement foam insulation board is a hydrophobic lightweight closed-cell insulation board whose main materials are cement, fly Ash, and silica fume which has been foamed, cured and cut. 3. aerated concrete panel is a lightweight concrete panel which has been autoclaved with lightweight materials, siliceous material and gas former as its raw materials. 4. rock wool panel, with natural igneous rock wool as its main raw material, is a cotton which is melted in high temperature by centrifugation and is pasted by thermosetting resin.

- Q: I am a manufacturer of refractory materials. I would like to receive some orders from abroad. I would like to know what foreign trade companies in Dalian place foreign orders abroad

- Dalian foreign trade companies are numerous, and fire prevention materials are also quite a lot

- Q: What is the appropiate thickness if fire resistant time for ultra thin steel structure coating is 2.5 hours?

- According to the "code for fire protection design of tall buildings", the fire resistance time of the component is at the first level: 3 hours, beam: 2 hours, floor: 1.5 hours;if fire resistance level is level the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. For fire resistant coating, fire resistance time for ultra-thin fire retardant coating is shorter than 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be used. Steel structure can adopt surrounding concrete or brick, fireproof coating, fireproof board coating and composite structure for its fire resisitance. Fire resisitance board can be divided into thick fire protection plate and thin plate, the thickness of the plate thickness of the fire is between 20 ~ 50mm, mainly includes calcium silicate fireproof board and expansion boring stone fire board, the main varieties are KB board, CF; thin fireproof plate is between 6 ~ 15mm thick, the main varieties include enforced short fiber cement plate, ordinary enforced fiber silicate calcium board and glass cloth reinforced inorganic board. As is known to all, steel structure usually will lose bearing capacity usually in 450 to 650 degree, leading to deformation, steel column and beam bending, and be no longer usable at last. Generally fire resistant limit of unprotected steel stucture is about 15 minutes. 1.5 hours;if fire resistance level is level the requirement for time of fire resistance component is the column: 2.5 hours, beam: 1.5 hours, floor: 1 hours. Steel structure an use surrounding concrete (or masonry), fire retardant coating, fire retardant plate and compround structure to achieve the required refractory limit. Hope my answer will help you.

- Q: What crusher is used for raw material of broken refractory material? What is the rough crushing process? What are the materials? Thank you!

- Common faults and causes of magnetic?separator. 1. Motor of magnetic?separator is overheated and its sound is not normal. Reasons for this failure are: 1) lubrication of bearing is bad or badly worn; 2)fan blade falls off or wears; 3)bad contact of switching circuit or disconnected to run a single phase; 4) voltage is too low. 2. Reasons for this failure due to overheated speed reducer are: 1) lack of oil or poor kerogen; 2) wear between gear and worm, or poor mesh; 3)poor lubrication of bearing or serious wear. 3. The sound of magnetic?separator during operation is abnormal, lattice ball mill. Cylinder is stuck by obstacle, and even the cylinder can not rotate. The bottom box vibrates. Reason for this failure is often that it is stuck by objects in drag flask, otherwise magnetic?patch falls off so that the cylinder screaks and pierce tube when it is serious. At this time, car should be stopped for maintenance and troubleshooting. Only when we master common faults and reasons of magnetic separator can we timely identify problems and solve problems. Better maintenance and repair of magnetic?separator equipment are an important prerequisite to properly use equipment and ensure the construction.

- Q: what's the requirements of refractory for forge furnace?

- . . . . . . . .

- Q: How to choose the material of refractory?

- Long using temperature of aluminum oxide fiber is 1400 ℃, containing chromium aluminum silicate fiber, quartz, high purity aluminum silicate fiber, long-term use of temperature is 1000-1200 ℃ has aluminum silicate refractory fiber according to different raw materials, advanced refractory fiber (such as alumina. Commonly used vitreous aluminum silicate refractory fibre is amorphous, zirconium oxide refractory fibre) using temperature is 1700 ℃ view as >and the best temperature is 1300 ℃. Crystalline refractory fiber are polycrystalline mullite fiber, including ordinary aluminum silicate fiber, alumina and graphite refractory fiber, etc. The use of common refractory fiber temperature is 1150 ℃;>

- Q: What needs to be paid attention to in the construction of high- temperature refractory mortar?

- 1. During the use of high- temperature refractory mortar, the minimum mortar joint should be 0.5mm and general mortar joint should be 3-5mm, which can solve the processing and fine grinding of refractory brick on the brick grinder. Besides, it is conducive to the health of workers, and can reduce the masonry effort, ensure the quality and speed up the construction progress. 2. When making urgent repair on the stove, if the joint is much too large, 2-3mm refractory pieces can be appropriately added into the high- temperature refractory mortar, and stirred to fill the joint so as to shorten the repair time and ensure normal production. 3. High- temperature refractory mortar can be painted inside various furnace body, and it should be guaranteed that the surface of the furnace body has no dust or debris before painting.

Send your message to us

Raw Materials for Refractory:70% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords