Raw Materials for Refractory:65% Alumina 120 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

65% Alumina 120 Mesh Calcined Bauxite with Low Price

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

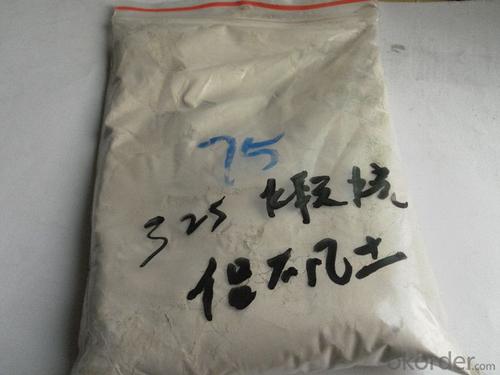

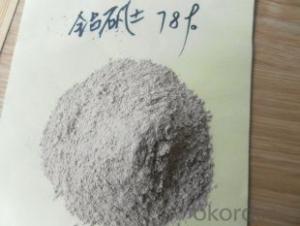

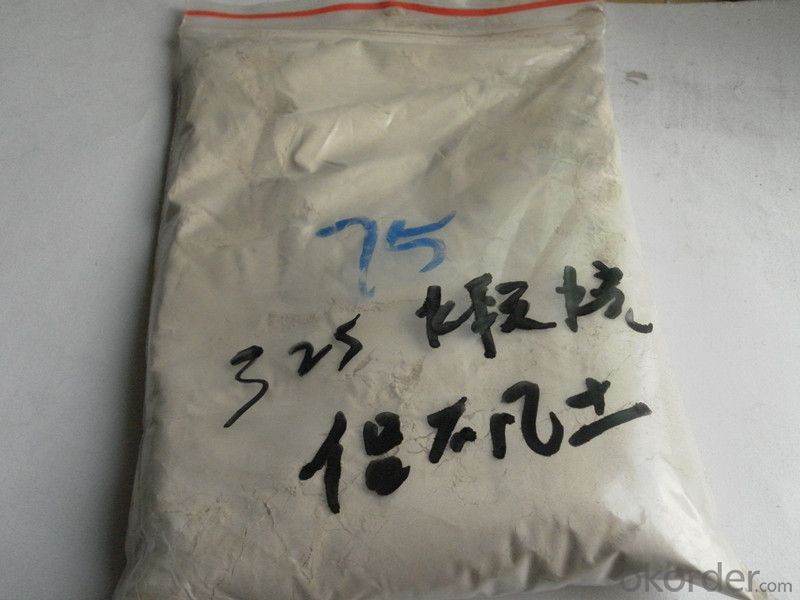

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What is the fire resistance thickness of the thin fire-retardant coatings?

- There is no detailed requirement on the thickness of the thin steelwork fireproof coatings and the thickness there refers to a certain thickness which must(at least) have fire resistance for a certain time. The thickness of fireproof coatings in engineering generally depends on the manufacturer's test reports. Our thin steelwork fireproof coatings: the fire resistance is 2.5 hours, the thickness is 4.9 mm, the fire resistance is 2.0 hours, the thickness is 3.5 mm, the fire resistance is 1.5 hours, the thickness is 1.75 mm, the fire resistance is 1.0 hours, the thickness is 1.17 mm.

- Q: What requirements should refractory materials meet?

- Ladle is an necessary equipment to undertake molten steel and continuous casting. As many kinds of steel needs to be processed in the ladle, including argon blowing tempering, alloy composition fine-tuning, refining dusting and vacuum processing, working conditions of the ladle lining have worsened. Their working conditions are as follows. (1) The temperature of molten steel is higher than mold casting ladle. (2) the molten steel stays longerin the ladle. (3) ladle lining are subjected to volatilization and agitation of molten steel under high temperatures and in vacuum. (4) The impact on the lining when undertaking steel liner when the impact effect. Therefore requirements of the ladle refractories are as follows: (1) It can resist high temperature. Molten steel should be able to withstand high temperatures without melting. (2) It can resist thermal shock and can withstand molten steel without cracking and spalling. (3) It can resist slag erosion. The ladle should be able to withstand the erosion of lining caused by slag and alkalinity changes of slag. (4) it should have sufficiently high temperature mechanical strength to withstand the agitation and scouring of molten steel. (5) lined should have certain swelling property so that lining will be united as a whole under the effect of hyperthermal molten steel.

- Q: What is the fire endurance of ceramsite concrete blocks?

- What is mentioned in fire?safety?rules is that the fire endurance of 240mm thick hollow brick of ceramsite concrete is 2.9h, so 190mm thick hollow brick is 3h. B05 thickness(mm), fire endurance(h). Combustion performance 100 4.0. Non-combustible component 150 6.0200 8.0300 〉8.0B06 100 〉4.0150 〉6.0200 〉8.0300〉8.0: The fire endurance performance of building blocks wall in the table is taken from the Tianjin Construction Standard "light steam pressing aerated?concrete?block" DB / T29-128.

- Q: Who knows the classifications of magnesia refractory?

- Magnesia chrome series products: The main ingredients of magnesium chromium series are MgO and Cr2O3. Periclase is the first phase and magnesia-chrome spinel is the second phase. Products belonging to this series are magnesium chrome brick and chrome magnesia brick. The main ingredients of magnesium aluminum series are MgO and Al203. As they generate MgO and Al203, all magnesium chromium series products contain magnesia material. magnesium calcium series products The main components are MgO and CaO. They have high melting points, which are important magnesia materials. 5, magnesium silicon series products: The main component of magnesite series is SiO2, when the C / S<5, SiO2 and MgO generate MgO.Al2O3 (forsterite). From the perspective of microscopic mineral, main products of pure aluminum series include magnesium aluminum brick, periclase spinel brick, corundum spinel brick and aluminum-spinel castable in unshaped materials. I hope this answer can help you.

- Q: How many hours of the fire endurance time of the rock wool laminboard?

- Hello! Manager! The fire endurance of the rock wool laminboard is generally two hours. If you need the fire?rating of the rock wool laminboard, then I recommend you to buy it from the standard factory ! The one with higher fire rating can use polyurethane edge banding rock wool board and handmade glass magnesium rock wool laminboard.

- Q: What's the difference between refractory metal raceway and fireproof raceway?

- Hello, I'm very glad to answer your question. As far as I know, anti-fire groove box is made by the polymerization reaction of high polymer material and halogen-free flame retardant polymeric material. It possesses excellent mechanical properties and environmental protection property, nice appearance, and diversified colors. As a kind of fully enclosed cable bridge, it is applicable for communication signals, and laying of computer cables and control cables of highly sensitive systems. When used in heavy corrosive environment and outdoor dust environment, it has good protective effect on cables. It boasts many advantages of fire retardance (fire resistance rating is above B grade), corrosion resistance, anti-aging, high strength, light weight, and easy installation. Hope my answer is helpful for you. Hope my answer can be accepted.

- Q: Who knows about the fire endurance of sintered shaly hollow bricks?

- Sintered shaly hollow bricks of Chu area have high intensity. The average compressive strength of them is up to 15.8, which matches with M7.5 cement mortar that has advantages of low water absorption, and good anti efflorescence performance. The fire endurance of sintered shaly hollow bricks should not exceed1050 degrees otherwise they will burn excessively. I, actually, think that the temperature should be controlled within 980 degrees. I hope my answer may help you.

- Q: How to classify the grade of wall fireproof and thermal inuslation matertial?

- External wall thermal insulation materials are mainly divided into grade A, grade B1, grade B2 and grade B3. In accordance with the current "Combustion Performance Classification Method of Building Materials", grade A thermal insulation material is incombustible?material and belongs to inorganic heat preservation material. However, grade A thermal insulation material is few in terms of the current market. There are only JETCO YT inorganic active wall thermal insulation material, glass wool, rock wool board, foam glass, vitrified micro bead and grade A fireproofing thermal insulation board. However, compared with grade A thermal insulation material, the more welcomed by the market is the organic insulation materials. Thermal insulation material that is determined as grade B is divided into three levels. Grade B1 is grade is flame retardant. Grade B2 is combustible. Grade B3 is flammable.

- Q: What are the differences between first-level fire-resistant materials and second-level fire-resistant materials?

- 1, these refer to fire resistance rating of building materials. 2, As for steel, elements that used in different parts should reach different duration of fire resistance according to fire resistance rating. For example, fire resistant pillars of first level can endure fire within 3 hours; the second level, 2.5 hours; the third level, 2 hours. With respect to beams, three levels of fire resistance are included.

- Q: What is the main material of fireproof wooden door?

- Fireproof door is an important part of fire-fighting apparatus and society fire prevention, so the quality and use of fireproof door is the key to the success of the fire prevention. Some customers don't know clearly that whether the fireproof door should install a door closer. Today I specially read the explanation of relevant state departments for fireproof door, in the explanation in 5.3.3, fireproof door should be installed fireproof door closer or set, so that normally open fireproof door can automatically close close-door device of the door leaf (except for the use of special parts, such as pipe shaft doors, etc.) in the event of a fire. In other words, except for some special parts which don't need to be installed door?closer, such as pipe shaft doors, other parts are required to install fireproof door closer.

Send your message to us

Raw Materials for Refractory:65% Alumina 120 Mesh Calcined Bauxite with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords