Quartz Stone Engineered Synthetic Stone Countertop Worktop Benchtop Vanity Solid Surface Fabricator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 180 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quartz Stone Engineered Synthetic Stone Countertop Worktop Benchtop Vanity Solid Surface Fabricator

Welcome to CNBM International Corporation, your gateway to premier building materials from China. As a professional intermediary, we bridge the gap between overseas buyers and China's splendid manufacturers. In collaboration with manufacturers, renowned suppliers of premium quartz stone countertops, we offer an expertly curated collection designed to elevate your kitchen and dining spaces with unparalleled style and functionality. Our quartz countertops, crafted from 99% high-purity natural quartz sand, undergo a rigorous process of high-pressure molding and medium-temperature curing, ensuring unmatched durability and timeless elegance. Each slab is meticulously polished to perfection, promising a flawless finish that enhances any interior design. At CNBM International Corporation, we take pride in providing customizable solutions that align with your distinct vision and style preferences, ensuring your space is as unique as you are.

Product Details

| Product Name | Premium Quartz Stone Countertops for Elegant Interiors |

|---|---|

| Type | Artificial Stone Solid Surface |

| Raw Materials and Processing Methods | 99% high-purity natural quartz sand bonding, high-pressure molding, medium-temperature curing, after 39 processes and 132,000 times of grinding. |

| Series of Products | Countertop Panels, Kitchen Panels, and Washbasin Series |

| Typical Slab Specifications | 3200x1600mm, 3000x1500mm, 3000x1200mm, 2800x1400mm, 2400x1400mm, or customized |

| Typical Slab Thickness | 30mm, 20mm, or customized |

| Harmonized System Code | 6810 9900 00 |

| Customs Declaration Name | Other Agglomerated quartz slabs of the type used for countertops |

| Country of Origin | China |

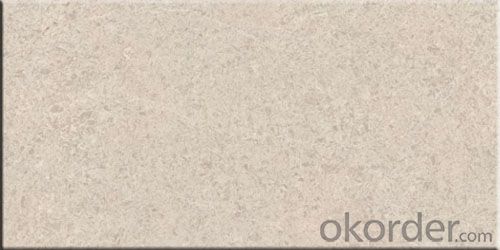

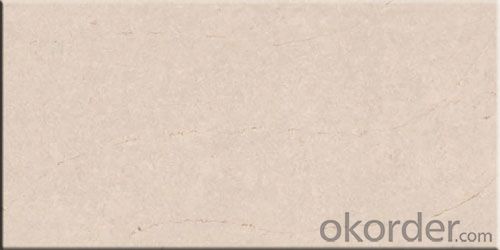

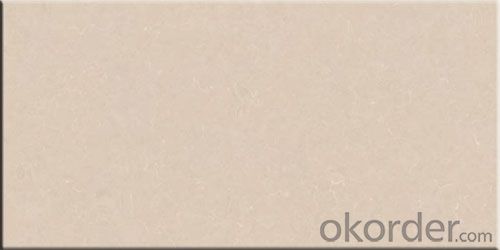

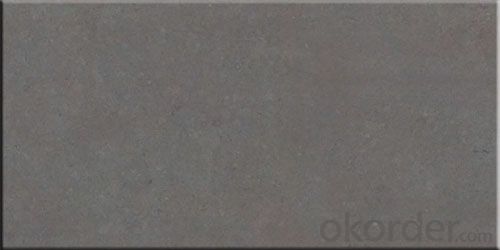

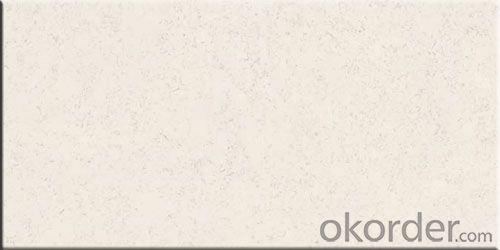

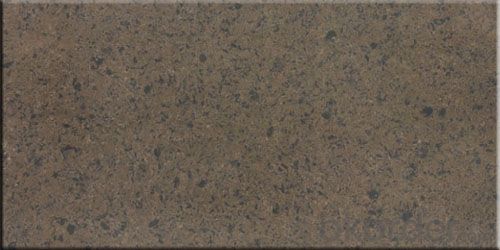

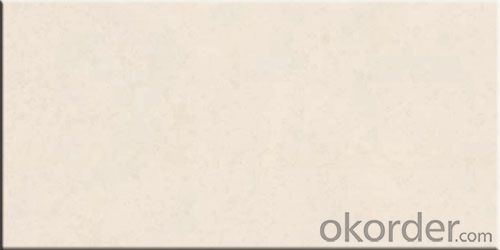

Customer Favorites: Quartz Colors, Patterns and Portfolio

QD Series

QD203

QD219

QD503

QD504

QD507

QD515

QD565

QD572

QD5012

QH Series

QH106

QH107

QH115

QH119

QH203

QH213

QR Series

QR181N

QR302

QS Series

QS100T

QS102

QS301T

QS713

QV Series

QV101

QV103

QV105

QV106T

QV107

QV108

QV111

QV113

QV116

QV208

QY Series

QY100

QY101

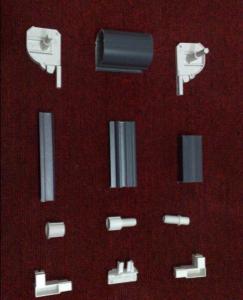

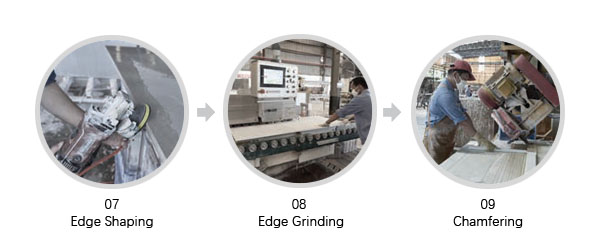

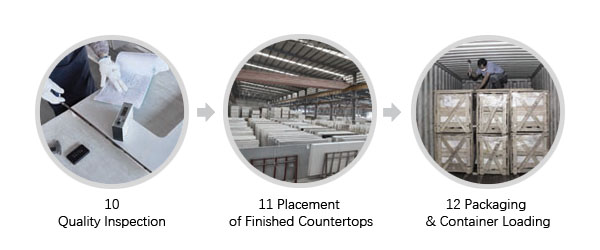

Fabrication Workflow

Workflow in Graphic

Workflow In Text

Drawing Auditing, Blueprint Auditing

Slab Cutting

Cutting Sink Hole

Waterjet Cutting

CNC Numerical Control Cutting

AB Glue Thickened Edges

Edge Profile Shaping (Rounded edges, Beveled edges, Ogee edges, Bullnose edges, Cove edges)

Edge Grinding

Chamfering

Quality Inspection

Placement of Finished Countertops

Packaging of Countertops and Container Loading

Quality Control in Our Fabrication Shop

Our fabrication shop boasts cutting-edge equipment like CNC routers, waterjet cutters, and automated polishers for precise and uniform countertops. We transform quartz slabs into custom countertops and vanity tops according to customer designs. Skilled workers carefully polish oval holes for undermount sinks on vanity tops. Our QC team checks every detail, from cut accuracy to finish smoothness, to meet our quality standards.

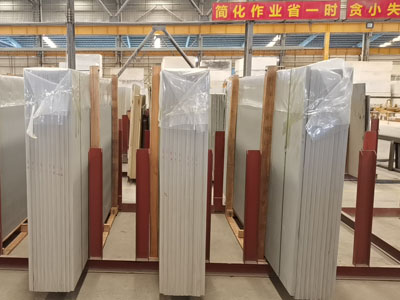

Quartz Stone Packaging: Ensuring Safety & Quality

We typically load six packs of quartz stone slabs in a 20-foot container. Each pack, wrapped in white protective material, is securely fastened to wooden A-frames to ensure stability during transport. This structure, commonly used for stone slabs and sheet materials, helps prevent damage.The six A-frame racks are also firmly secured within the container.

For slabs measuring 3000x1000mmx20mm, it carries 17 slabs with each A-frame rack weighing approximately 3.3 tonnes.

Customization Options

Our facility is fully equipped to handle an array of customization requests, ensuring that your countertop can be precisely tailored to suit your unique preferences. With an extensive palette of color options and a variety of edge profiles to choose from, our diverse selection empowers you to create the countertop you need.

- Q: Cabinet countertops material, how to distinguish between stone and quartz stone

- Quartz stone countertops are not afraid of stab wounds.

- Q: What are the countertops of the cupboard? What's the difference?

- Cabinet table material introduction: US resistant plate: the most scratch-resistant and clean, in addition to bright-type US-resistant plate, in fact, can be used cloth clean. Solid wood door: feel good and the door surface has a simple bump changes. Because it is natural grain, easy to have different shades of color, and the price is better than the United States resistant plate. Piano paint: the biggest advantage is no seams, waterproof function is good, and can be re-paint repair, so that the system door in the highest price. Crystal door: the surface material for the acrylic, because it seems crystal, so generally become a crystal door. Good moisture resistance and low price. Use a long time will produce atomization of the situation. Most people choose the United States resistant plate countertops, as the pearl board, marble and artificial stone is used in the kitchen more. Pearl board and the United States resistance to board texture is close, more durable, unlike the texture of the marble is difficult to maintain, and the brittle high easy to produce cracks. Artificial stone texture is good, can be used for seamless processing, for those who want to do long or L-type table is a good choice.

- Q: What kind of material selection is better? Affordable Another color is more modern how to match the door with it?

- With black granite countertops, accompanied by white or [light green, light pink, light blue, beige, silver gray] door. Granite is recommended with a black gold sand. Black sands are very bright, black surface with a fine sand around 300 square, a kitchen down to spend 2000, than to buy those brand-name companies to produce a lot cheaper and never change color.

Send your message to us

Quartz Stone Engineered Synthetic Stone Countertop Worktop Benchtop Vanity Solid Surface Fabricator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 180 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches