Laminating Wood Boards - High Quality Okoume Face Falcata Blockboard/Core/Chipboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 cubic m³

- Supply Capability:

- 1000cbm/week m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

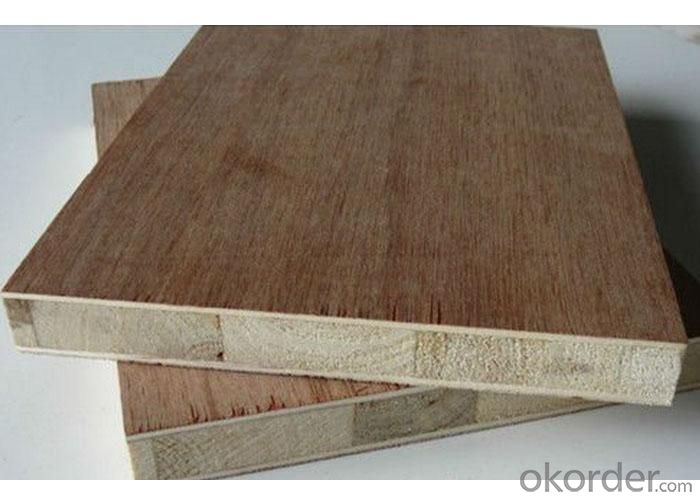

Specification of High Quality Okoume Face Falcata Blockboard /Core/Chipboard

| High Quality Okoume Face Falcata Blockboard /Core/Chipboard | |

| Usage | Used for interior decorationfurniture,buildings&construction |

| Core | Poplar, pine ,falcata paulownia ,hardwood or as request |

| Face and Back | Okoume,poplar,birch,pine,hardwood,ash,bintangor,oak and melamine paper. |

| Dimension | 1220*2440,1250*2500mm, or as request |

| Thickness | 12-30mm |

| Glue | Melamine,MR.WBP,E0,E1.E2 |

| Moisture Content | Below 10% |

| Density | 600-700kg/m |

| Formaldehyde release | E0≤0.5mg/L,E1≤1mg/L,E2≤5mg/L |

| Advantage: | Strong nail holding, waterproof, easy work,anti-corrosion,low formaldehyde emission and environment protecting etc. |

| Certificate | CARB/ISO9001 |

Features of Blockboard

(1)Low formaldehyde emission

(2)Good stability and high bonding strength,strong screw holding.

(3)Flat and smooth face/back,nondistortion

(4)Soundproof and moisture resistant,

(5)Light structure,less glue consumption,save cost

(6)Beautiful surface,wide range,and convenient to use.

Packing:Pallets

---Inner packing:0.2mm plastic bag.

---Outer packing:plywood or carton packing with steel strips.

Delivery time:Within 15-30 days after getting final confirmation.

- Q: The production process of the core

- General core moisture content of 8% - 12%, the north air drying can be 6% - 12%, the South air humidity, but not more than 15%.

- Q: Big core board according to the merits of the material and the texture of the surface material points

- Different materials, different quality, Daxin board according to the merits of the material and the texture of the surface material is divided into "excellent goods"

- Q: How to choose the attention of fine wood

- For example, about 100 square meters of the room around the use of large core board not more than 20, in particular,

- Q: The role of fine wood

- doors and windows and Sets, partitions, false walls, heating hood, curtains, etc., the most widely used.

- Q: There are many kinds of material

- The texture is very light, soft, absorb water, grip nail difference, easy to dry, made of the plate in the course of the use of water evaporation, the plate is easy to dry deformation.

- Q: What are the advantages of blockboards?

- Blockboard grip screw force is good, high strength, with quality Kennedy, sound absorption, insulation and other characteristics, Blockboard moisture content is not high

- Q: What are the requirements of the blockboard?

- but also through the drying kiln for strict drying process control. In addition, the level of its processing equipment not only requires a lot of capital investment

- Q: How do blockboards be classified according to board core structure?

- Five blocks of blockboard: in the core of the two large surface of the paste on the two layers of the board made of blockboard.

- Q: Blockboard and maple board which is good?

- Of course - pure fir blockboard good reasons: pure fir wood light, not easy to deformation of pure wood plate is not good

- Q: What is fine wood board?

- Blockboard commonly known as Daxin board, wood core board, woodworking board, [1] is made of two pieces of the middle of the pressure from the stamping of wood.

Send your message to us

Laminating Wood Boards - High Quality Okoume Face Falcata Blockboard/Core/Chipboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 cubic m³

- Supply Capability:

- 1000cbm/week m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords