Tongue and Groove PVC Ceiling - Qualified Decorative Ceiling Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

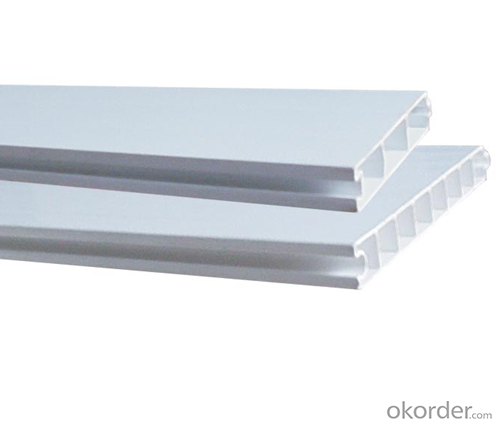

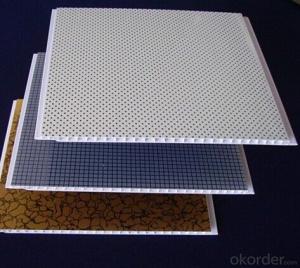

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

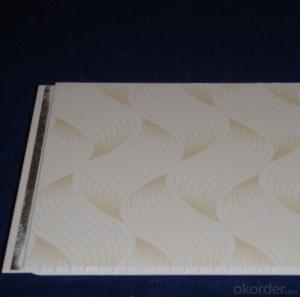

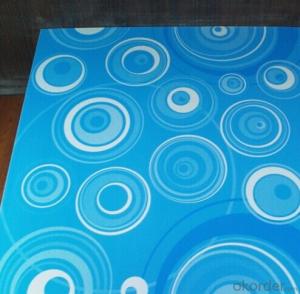

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Any other specifications are also available here.

The hottest type/specs of the PVC panel: | |||||||||

Luck PVC | PVC CONTENT | Width | Thickness | Length | N.W. | Packing | Loading in a 40'HQ | ||

mm | mm | M | Kg/Sqm | packages | amount/Sqm | ||||

1 | 35%-75% | 200 | 5 | 5.95 | 1.7 | 10 pcs/PE film package | 1142 | 13589.8 | |

2 | 6 | 5.95 | 1.9 | 900 | 10710 | ||||

3 | 7.5 groove | 5.95 | 2.1 | 745 | 8866 | ||||

4 | 8 | 5.95 | 2 | 714 | 8496.6 | ||||

5 | 250 | 4 | 5.95 | 1.5 | 1070 | 15916 | |||

6 | 4.5 | 5.95 | 1.65 | 941 | 13997 | ||||

7 | 7.5 | 5.95 | 2.2 | 591 | 8791 | ||||

8 | 11 | 5.95 | 3.9 | 416 | 6188 | ||||

9 | 300 | 9 | 5.95 | 2.5 | 429 | 7658 | |||

10 | 595/600 | 7 | 0.595 | 2.9 | 20pcs/carton | 1160 | 8213 | ||

Hundreds of patterns & colors are provided. New patterns are adding ceaselessly, which can keep you on the front of the market

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

Quality Test:

No. | Test Items | Technical Requirements | Detection Result | Single Judge | |

1 | Appearance | Fulfill | Qualified | ||

2 | Flexibility mm/m | <1.5mm/m | 0.48 | Qualified | |

3 | Thickness mm | Faceplate | >0.4 | 0.4 | Qualified |

Base plate | >0.3 | 0.32 | |||

4 | Heating Rate % | <6.0 | 0.6 | Qualified | |

5 | Heated State | No bubble, craze or spot | Fulfill | Qualified | |

6 | Resistance of acetone | No defects | Fulfill | Qualified | |

7 | Dart drop impact | 0.25kg/0.5m,10 times, Pass when keep unbroken above 6 times | pass | Qualified | |

8 | Size Variation in High/Low Temperature | ±0.6% | -0.16 | Qualified | |

9 | Nail resistance | no visible cracks | Indehiscent | Qualified | |

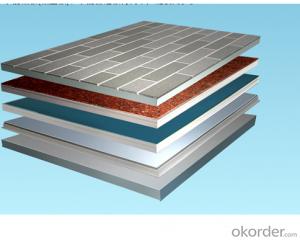

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

Welcome to visit our factory, welcome all interested parties to establish long terms business relationship with us under the mutual benefit and kindly friendship.

- Q: What is the difference between WPC and PVC flooring?

- WPC refers to the wood-plastic composite flooring, may be PVC / PE / PP + wood powder made out. PVC is PVC plastic, ordinary PVC flooring may not add wood powder.

- Q: Pvc crystal plate 1.6mm per square meter with multiple

- If the stealing thickness may be smaller, and normal manufacturers will make a negative tolerance. In addition some will be affixed to the protection or paper, it is different, 2160 grams is the net PVC.

- Q: Shop on the ground PVC plastic plate soft PVC or hard PVC?

- Coil and sheet, the former belongs to the soft, the latter belongs to the hard.

- Q: Density board and PVC which expensive

- The same specifications PVC expensive

- Q: Pvc plastic acid corrosion

- Resistance, people's metering pumps are used above.

- Q: What are the disadvantages of PVC glue?

- Not wearable

- Q: How many years can I use a PVC

- Look outdoors or indoors, and ordinary indoor use with ten years, outdoor aging soon, will become brittle, the specific use of the year to see the quality of the.

- Q: Pvc board on the human body is not harmful

- Pvc board is not harmful to the human body. PVC is non-toxic harmless, only in the extreme temperature or combustion will produce harmful gases or substances PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: PVC board inkjet and PVC board photo which effect is good

- Direct spray on the pvc board is used uv flat panel printing process, Pvc board photo you should refer to the adhesive or car stickers directly mounted on the pvc board. The difference between the two processes is very large, the price gap is also great Uv flat printing is in the pvc direct injection, because uv is the original imported ink to play, waterproof, sunscreen, color lasting .. and a sense of bumps .. good texture Photo is mounted up, not lasting, especially domestic use are on behalf of the ink

- Q: In electrical drawing, how many PVC circular boxes needed if you have 6 ceiling lights?

- Depends. One for each lighting point. Then how many switches are there? Are you branching off from any point (you'll need one for every split in the cables) or will you run from the first box through the rest to the last - then you don't need any extras for branching. Your question is not really specific enough.

Send your message to us

Tongue and Groove PVC Ceiling - Qualified Decorative Ceiling Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords