Q195 Q235 steel round bar supplier round bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

Tangshan Q195 Q235 steel round bar supplier round bar

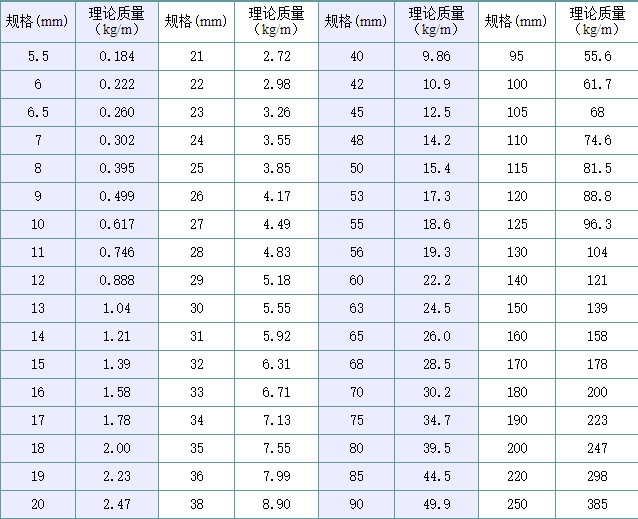

Dia:5.5-250mm

Length:1-12 or customized

Packing: Naked and in bundles tied with steel wire rods or steel strip

Moq:25ton

Delivery time:within 30-45 days

Payment:TT or 100% LC

Hot Rolled Steel Round Bar is a mild steel solid steel bar that is ideal for all general fabrication, manufacturing and repairs. Steel Rounds are widely used in industrial maintenance, agricultural implements, transportation equipment, ornamental iron work, fencing, artwork, etc. This steel shape is easy to weld, cut, form and drill with the proper equipment and knowledge. Metals Depot stocks many sizes of steel round at wholesale prices in ready to ship precut and mill lengths or you can order online just what you need custom Cut to Size in small or large quantity.

- Q: What is the carbon content in steel round bars?

- The carbon content in steel round bars varies depending on the grade and type of steel being used. Generally, carbon steel round bars contain carbon in the range of 0.08% to 1.5%. Higher carbon content provides increased strength and hardness, but it also decreases weldability and ductility. The specific carbon content in steel round bars is determined during the manufacturing process and can be specified by the customer based on their desired mechanical properties and application requirements.

- Q: How are steel round bars used in the construction of railways?

- Steel round bars are commonly used in the construction of railways as they provide strength, durability, and stability to the railway tracks. These bars are typically laid horizontally and are used to support the rails, ensuring that they remain in place and can withstand heavy loads and constant train traffic. The round shape of the bars allows for uniform distribution of weight and reduces the risk of structural failure. Additionally, steel round bars are often used to reinforce the concrete foundations and structures associated with railway construction, further enhancing the overall stability and longevity of the railway system.

- Q: What are the different methods of cutting steel round bars?

- There are several methods for cutting steel round bars, each with its own advantages and limitations. Some of the most commonly used methods include: 1. Abrasive cutting: This method involves using a rotating abrasive wheel to grind through the steel round bar. It is a fast and efficient method, but it can produce a rough cut surface and generate a significant amount of heat. 2. Bandsaw cutting: Bandsaw machines are commonly used to cut steel round bars. They consist of a continuous band of toothed metal that rotates around two wheels, slicing through the material. Bandsaws provide a smooth and precise cut, but they are slower than some other methods. 3. Cold saw cutting: Cold saws are specifically designed for cutting metal, including steel round bars. They use a circular saw blade with teeth that have been specially designed to withstand the hardness of steel. Cold saws produce clean and accurate cuts, but they are generally slower than abrasive or bandsaw cutting. 4. Plasma cutting: Plasma cutting is a high-energy cutting method that uses a focused jet of ionized gas to melt and remove the metal. It is commonly used for thicker steel round bars and can produce a precise and clean cut. However, it requires specialized equipment and can be more expensive than other methods. 5. Laser cutting: Laser cutting uses a high-powered laser beam to melt and vaporize the metal, resulting in a precise and clean cut. It is a versatile method that can be used for various thicknesses of steel round bars. However, it requires expensive equipment and may not be suitable for all applications. Ultimately, the choice of cutting method depends on factors such as the thickness and hardness of the steel round bar, the desired cut quality, the available equipment, and the specific requirements of the project.

- Q: Can steel round bars be used for making propeller shafts?

- It is indeed possible to utilize steel round bars in the production of propeller shafts. The utilization of steel in propeller shafts is widespread due to its robustness, endurance, and ability to withstand corrosion. In particular, round bars are frequently favored due to their shape, which offers exceptional strength and load-bearing capabilities. The decision regarding the steel grade and specific properties will be contingent upon the propeller shaft's requirements, such as the desired dimensions in terms of length, diameter, and torque capacity. Moreover, factors like cost, weight, and manufacturability may also play a role in influencing the selection of steel round bars for propeller shafts.

- Q: Can steel round bars be used in the defense industry?

- Indeed, in the defense industry, steel round bars find utility. Steel, being a remarkably resilient and sturdy substance, proves fitting for diverse applications within the defense sector. The production of vital defense equipment, such as gun barrels, armor plates, missile casings, and other essential components, can be achieved using steel round bars. The durability of steel guarantees that these components endure high-pressure circumstances and furnish the essential safeguard and assistance demanded in defense applications. Moreover, steel round bars can be customized through machining, welding, or heat treatment to fulfill the distinct necessities of various defense systems, rendering them a material choice ideally suited for the industry.

- Q: Can steel round bars be used for making engine parts?

- Absolutely! Engine parts can indeed be made using steel round bars. In fact, steel round bars are commonly employed in the production of engine components. This is primarily due to their remarkable qualities such as exceptional strength, long-lasting nature, and ability to withstand extreme temperatures and corrosion. These bars can be skillfully shaped and resized to fashion a wide array of engine parts including crankshafts, camshafts, connecting rods, and valves. By utilizing steel round bars, the desired mechanical attributes and structural integrity necessary for optimal engine performance and reliability can be ensured. Furthermore, these bars can be subjected to heat treatment and surface treatment techniques to further augment their properties, rendering them incredibly suitable for engine applications.

- Q: What are the advantages of using aluminum-magnesium alloy steel round bars?

- Aluminum-magnesium alloy steel round bars offer several benefits: 1. Lightweight: With its lower density compared to traditional steel, aluminum-magnesium alloy steel is a lightweight material. This is advantageous in industries like aerospace and automotive where weight reduction is crucial. It improves fuel efficiency and increases payload capacity. 2. Corrosion resistance: Aluminum-magnesium alloy steel has excellent resistance to corrosion. The addition of magnesium enhances its ability to withstand harsh environments, including moisture, chemicals, and saltwater. It is ideal for marine applications and areas with high humidity or corrosive atmospheres. 3. High strength-to-weight ratio: Despite being lightweight, aluminum-magnesium alloy steel is highly strong. It offers a superior strength-to-weight ratio compared to other materials, allowing for the construction of durable structures. This is valuable in applications like construction where both strength and weight are important factors. 4. Excellent machinability: Aluminum-magnesium alloy steel is easy to machine, making it suitable for a variety of fabrication processes. It can be cut, drilled, and welded with ease, enabling efficient manufacturing and assembly. This saves time and costs while allowing for complex designs and customization. 5. Thermal conductivity: Aluminum-magnesium alloy steel has excellent thermal conductivity, facilitating efficient heat transfer. This property is valuable in applications such as heat exchangers, cooling systems, and electrical conductors. It prevents overheating and improves overall performance. 6. Recyclability: Aluminum-magnesium alloy steel is highly recyclable, making it an environmentally friendly choice. It can be melted down and reused, reducing the need for raw materials and minimizing waste. Recycling aluminum-magnesium alloy steel requires less energy compared to primary production, making it a sustainable option. In conclusion, the advantages of aluminum-magnesium alloy steel round bars make it a versatile and cost-effective material for various applications. Its lightweight nature, corrosion resistance, high strength-to-weight ratio, excellent machinability, thermal conductivity, and recyclability make it a preferred choice in industries where these properties are essential.

- Q: Can steel round bars be used for making rebar?

- No, steel round bars cannot be used for making rebar. Rebar, or reinforcing bar, is specifically designed and manufactured with deformations or ribs on its surface to enhance the bond with concrete. These deformations provide better grip and prevent slippage between the rebar and concrete, thus improving the structural integrity of a reinforced concrete structure. On the other hand, steel round bars have a smooth surface and lack the necessary deformations, making them unsuitable for rebar applications. It is important to use rebar that meets the required standards and specifications to ensure the safety and durability of the concrete structure.

- Q: What is the difference between a seamless and a welded steel round bar?

- The main difference between a seamless and a welded steel round bar lies in their manufacturing processes. A seamless steel round bar is produced by piercing a solid cylindrical billet, while a welded steel round bar is created by welding together multiple pieces of steel. This results in a seamless bar having a smoother surface and uniform composition, making it stronger and more resistant to corrosion. On the other hand, a welded round bar may have visible seams due to the welding process, which can affect its strength and durability.

- Q: How do you store steel round bars to prevent damage?

- To prevent damage to steel round bars, they should be stored in a clean and dry environment, away from moisture and direct sunlight. It is recommended to store them horizontally on a flat surface or on racks, ensuring they are not stacked too high to avoid bending or warping. Additionally, using protective coverings or plastic caps on the ends can help prevent any potential scratches or dents during storage.

Send your message to us

Q195 Q235 steel round bar supplier round bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products