Plastic Tubes - PVC Pressure Pipe (ASTM Sch 80) 0.63-1.6MPa, GB/T10002.1-2006

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of PVC Pipe :

Material: Virgin Rigid PVC resin, no recycle material

Process: vacuum forming extrusion

Color: various colors, we can make color according to Panton card No.

Application:construction, home decoration, stationery&toy, advertising, ornament, etc.

Common Feature: high glossy, water proof, damp proof, termite proof, shock proof, fire retardant, Maintenance free, light weight ,easy to install, economical, durability, recyclable

2.Features of PVC pipes :

1) Light weight, easy to load and unload: PVC pipe is very light, convenient to handle loading unloading, and installing.

2) Good chemicals and drugs resistance: PVC pipe has its excellent resistance to the erosion caused by acids and alkalines, a great help to the chemical industries.

3) Small resistance to fluidity: The smooth surface reduces resistance to the fluids. Its roughness coefficient is only 0.009, much less than other pipes, Under same discharges, smaller cabibre of the pipe can be uesd.

4) Strong mechanical strength: Good resistance to water pressure, outside impact and pressure, is satisfied under any conditions.

5) Water quality unaffected: The solution tests on the PVC pipe show no affect on water quality when the water flows through is. It is considered the best piping material for running water works.

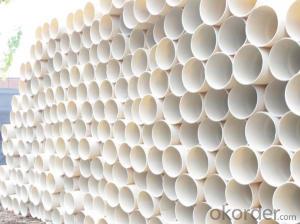

3.PVC Pipe Images:

4.Specifications of the PVC pipe:

1) Material: pvc pipe unplasticized polyvinyl chloride

2) Standard: GB, ISO9001, ISO14001

3) Color: white pvc pipe, grey pvc pipe , etc.

4) Specific Gravity:g/cm3, 20(C): 1.35 - 1.55

5) Dichloromethane Resistance Test: No attack

6) Falling Weight Impact Test: TIR, %, 0(C) <=10< span=""><>

7) Tensile Yield Strength: Mpa >=40

5.FAQ

Q:What is you MOQ?

A:As customer’s request.

Q:What is the production ability? or delivery time?

A:Our production ability support 40HQ order finish in one week.

Q:What is your payment?

A:TT or CC.

Q:For urgently doubts,who online?

A:Sales and marketing Manager 24hours online service.

- Q: My PPR plastic pipe leaking, how to do ah?

- If it is a stop valve, then look at the ball valve or globe valve, if it is the problem of the spool, which can even change the spool, and the other should be all right.

- Q: UPVC what material is the pipe and the HDPE plastic pipe?

- UPVC is modified polyvinyl chloride. The tubing is brittle, flexible, and has a weak connection. HDPE is high-density polyethylene, flexible tubing, -60 degrees - 40 degrees can be safely construction. The use of hot melt and electrofusion connection method is very strong, generally used for drinking water supply pipe, gas pipe, coal pipe, etc..

- Q: I remember having it as a kid and am wanting it for some stocking fillers! cant for the life of me remember what its called. have looked up all kinds of things on the net and not found a thing!

- I okorder /

- Q: hi I don't really know a lot about plumbing but today my bathroom sink was clogged so I took the j looking pipe apart and when I did a plastic tube looking thing fell out from the first pipe and when I tried to put everything back together that thing wouldn't stay. help?

- Go to a hardware store or a big store like WalMart and ask where the plumbing section is, then while in that aisle ask where the j-tube and other undersink plumbing parts are. It's easier to install new stuff than it is to try to fix old stuff that might be brittle. Also get some pipe dope and telfon tape. Teflon is a brand name but there are a lot of companies that make the same kind of thin PTFE tape. It's not a sticky tape.

- Q: Can plastic tubes be used for fuel lines?

- Yes, plastic tubes can be used for fuel lines.

- Q: If you had 32 plastic test tubes, what would you use them for?

- making test tube babies.

- Q: I have a big section of vinyl/plastic tubing does anyone have any ideas for what i could make out of it? Thanks in advance!

- A really long CRAZY STRAW! LOL

- Q: What are the different materials used to make plastic tubes?

- Plastic tubes can be made from a variety of materials such as polyethylene, polypropylene, PVC (polyvinyl chloride), polystyrene, and PET (polyethylene terephthalate).

- Q: What are the advantages of using plastic tubes in the marine industry?

- There are several advantages of using plastic tubes in the marine industry. Firstly, plastic tubes are lightweight, which makes them easier to handle and transport. This is particularly beneficial when it comes to installing and maintaining marine structures. Secondly, plastic tubes are resistant to corrosion, which is important in marine environments where exposure to saltwater can cause damage to metal pipes. Plastic tubes also have good chemical resistance, making them suitable for transporting various types of fluids and chemicals commonly used in the marine industry. Additionally, plastic tubes are durable and have a long lifespan, reducing the need for frequent replacements. They are also cost-effective compared to other materials, making them an economical choice for marine applications. Overall, plastic tubes offer a range of advantages including weight savings, corrosion resistance, chemical resistance, durability, and cost-effectiveness in the marine industry.

- Q: I'm building a science project with my little sister, and we quite frankly need some help. The plan is to make a little rollercoaster out of plastic tubing as the track. It's kind of thick, so it doesn't bend very well. We've been straightening it out for a couple days, but it's still slightly wavy. We need to get it into a solid position. The plan is to support it on some boxes, and maybe tape it down so it holds it's form.But, there is a part in the rollercoaster where it needs to be extremely straight. Any ideas??

- Classic Plastic

Send your message to us

Plastic Tubes - PVC Pressure Pipe (ASTM Sch 80) 0.63-1.6MPa, GB/T10002.1-2006

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords