Plastic Sheets - PVC/PE/ABS Extrusion Machine for Clear/Color Acrylic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Characteristic

high density polyethylene price

1, good quality

2, virgin material

3, high performance

4, excellent hardness

high density polyethylene price (HDPE) Products

Product Description

1. Weldable/Bendable - suitable for fabrication

2. UV Resistant - Black only

3.Physiologically inert - approved for food applications (Natural only)

Applications of acrylic sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

Specification for the Acrylic Sheet

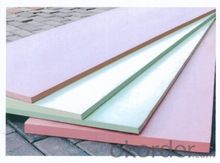

| Size | 4*6ft, 4*8ft, 1220*1830mm, 1220*2440mm |

| Thickness | 1.5-50mm |

| Colors | Clear & Colors, can be customizedt |

| Density | 1.2 g/cm3 |

| Quality | A Grade, can be used for advertising, letter signage, cutting |

| Certification | SGS |

| MOQ | 100 Pieces/Sheets |

| Payment | T/T, or Western Union, 30% deposit, balance before delivery |

| Package | PE film or Kraft Paper on both sides, wooden pallet |

| Delivery time | 10-15 days |

FAQ:

Q: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities, they are mainly famous ,

such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

- Q: For my Drawing on the Right Side of the Brain course, Betty Edwards includes a view finder containing an overhead projector sheet as one of the materials. I assumed any sheet of plastic (i.e. a plastic sleeve made for a binder) would work, but now I discovered she wants the reader to write on it using a white board marker (and wipe it off afterwards). Any ideas on how I can get a one or two overhead projector sheets, or else, are there any easy alternatives?

- Go to your nearest middle school or high school and ask if you can get a couple of sheets from one of those teachers or something. When those sheets gets a little too clouded or overused, teachers tend to throw them away and use newer ones. U can ask for the old ones. Hope this helps.

- Q: Can plastic sheets be used for architectural applications?

- Yes, plastic sheets can be used for architectural applications. They are commonly used in construction for various purposes such as roofing, cladding, insulation, and glazing. Plastic sheets offer advantages such as durability, lightweight, flexibility, and cost-effectiveness, making them suitable for architectural projects.

- Q: Are plastic sheets water-resistant?

- Yes, plastic sheets are generally water-resistant.

- Q: FRP-Fiberglass reinforced plastic, how much should i pay per sheet for install

- It depends on how the room is configured and how you plan to have it installed. Here is how I install it. #1. All the materials and adhesives are on the job ready to go. We apply adhesive to the entire backside of frp sheets with a trowel. #2. Moldings also affect the labor costs. We usually cut the sheets close to the ceiling and then caulk with white silicone, we also use 2 pc. divider strips and full length outside corner guards about 3/4 to each side. #3. After sheets are all installed we snap on top pc. of divider with a rubber mallet. #4. Sheets are cut with a pair of electric shears. I allow 45 minutes per sheet in a normal situation which for us is usually a lunch room or break room in a commercial manufacturing facility. I add more time to that if there is a lot of cutting for around doors/windows/electrical outlets/cabinets/etc. sometimes I add up to 30 more minutes per sheet. In restrooms it's about 2 hours per sheet if toilet partitions have to be removed to install panels. Residential which you are probably talking about in a normal room figure 45 minutes per sheet (2 man/woman crew) up to 8' tall walls. I figure around $40 hour for a couple good carpenters $25 hour if you are paying cash.Remember that 45 minutes per sheet is per man/'woman which is a total of about 1+1/2 hr. per sheet in labor.You furnish and have all the materials delivered and ready to go.

- Q: Can plastic sheets be used as barriers?

- Yes, plastic sheets can be used as barriers to separate or block off areas, as they are lightweight, flexible, and can effectively prevent the transmission of dust, dirt, or liquids.

- Q: I am trying to fugure out how to create a flexable seem out of a sheet of plastic. For example if you had a 12x12 sheet of plastic 1/16 thick and you wanted to fold it in half to create two 6x12 flaps. How would you create a seem at the fold that could be easly folded and unfolded repeatedly for a long duration?

- You could do this with a living hinge. Co-extrude the plastic profile with rigid plastic connected with the flexible plastic living hinge. Long duration needs to defined.

- Q: Where do u buy sheets of plastic mirror used in magic that are about 5 feet by a little over 2 feet?

- Builder's Square (now out of business) used to carry them. I bought some and attached them to a three-panel screen to use when I practiced tap dancing. Home Depot and Lowe's carried them at one time in their plexiglas sheets department, near the hardware, and in their ceiling panels department, near the lighting. If you have a Sutherlands Lumber near you, you might check with them.

- Q: What are the basic performance and waterproof function of plastic drainage board?

- The utility model relates to a concave convex hollow vertical rib structure of a waterproof and drainage protection plate, which can rapidly and effectively export rainwater and greatly reduce or even eliminate the hydrostatic pressure of the waterproof layer, and the active water guiding principle can achieve the effect of active waterproof.

- Q: I used to work in pastry but now I am a full time mom and I'd like to use these things I once used at work for my son's lunches, but I can't seem to figure out the exact name of them. They were clear plastic sheets that you'd put a slice of cut cake on top of, then you'd bring the sides of the plastic up the sides of the cake slice for stability and also to maintain some freshness. They were always clear and sometimes had pretty designs on them. Any clue?

- they're called cake collars or acetate sheets and they can either be made out of clear/colored plastic or parchment paper. they usually use them in commercial baking for places that serve slices of cakes. i hope that's what you need

- Q: Are plastic sheets resistant to moisture condensation?

- Yes, plastic sheets are generally resistant to moisture condensation due to their impermeable nature.

Send your message to us

Plastic Sheets - PVC/PE/ABS Extrusion Machine for Clear/Color Acrylic Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords