PVC Foam Board Sheets - Plastic Sheets Manufacturer, Exporter and Supplier

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

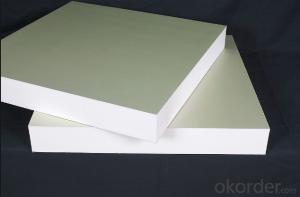

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q: My house is 50 years old and is lacking in insulation in the garage ceiling. Above the garage are bedrooms. Currently there is 3 of fiberglass with an aluminum vapor barrier within a 2x10 joist. I'd like to put R-30 fiberglass in the cavities but the 25' rolls of insulation are unfaced and the faced R-30 rolls are only in 48 batts. 4' sections are easier to put up but that is not a concern of mine.

- Don't use a plastic sheet, use 15# asphalt impregnated felt or a fabric like Tyvek. The vapor barrier must be able to breathe or you run the risk of trapping dampness which will lead to mold.

- Q: why is a sheet of paper easier to tear than a sheet of plastic the same thickness?

- It's to do with the way they are made and what they are. The fibres in plastic are thicker than the fibres in paper.

- Q: Behr has special paint, can this be done with other paint?

- Behr is a good quality paint, but there are other paints of equal quality that are less expensive that can be used for the same faux techniques. Another thing you may consider is that decorators have used everything from plastic shopping bags to saran wrap to achieve the same look for less expense. Paint is much like any other product on the market. There are very cheap products that won't hold up, then there are reputable brands that have been around for years that still work just as well as the newer brands out there. Just because something is more expensive doesn't always mean that it better. Interior decorating doesn't have to be expensive, and long before stores started selling special rollers, twisted up rags and other tools of the trade painters and designers were using paper bags, feathers and other odd medium to create these faux finishes. It's just that mfrs have found ways to market and profit from the ideas.

- Q: Is it possible to melt down plastic bags or bottles to make transparent sheets for a house's roof?

- can and it very easy. melted the plastic on the temperature 105°C to 138°C (depending on the type of plastic used) then moulded by the colded mold (so that the plastic is not attached to the mould)

- Q: What are the plastic plates that can be welded?

- Most plastics can be welded. For example, the commonly used PP, POM and PA can be welded.

- Q: Basically what are the pros and cons of plastic covering the ground in a effort to keep in warms, moister and produce a vegetable crops sooner in the ground,and bigger.Please don't say google people over there tend to get long winded, rabble on, and get off subject sometimes. Thank you in advance!!

- Plastic sheeting might help until the temperatures rise enough, but I never use plastic mulch. Mulch is supposed to decompose and amend the soil, and plastic mulch doesn't do that.

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are commonly used as a cost-effective and easy-to-install option for temporary or low-traffic areas. However, it is important to note that plastic sheets may not be as durable or long-lasting as other flooring materials, and their suitability for specific applications should be assessed based on factors such as foot traffic, moisture resistance, and desired aesthetic.

- Q: Can plastic sheets be used for art and crafts?

- Yes, plastic sheets can definitely be used for art and crafts. They are versatile and can be easily cut, shaped, and molded to create various art pieces, such as sculptures, mobiles, stencils, and even jewelry. Plastic sheets also come in different colors and transparency levels, allowing artists to experiment with different effects and techniques. Additionally, they are durable and lightweight, making them suitable for a wide range of craft projects.

- Q: I have to do environmental poster for a class and wanted to know how thick the sheet of plastic is.

- UNANSWERABLE There is no way any one organization, country or program to calculate such. WHY ? Besides the natural pollution that occurs due to various leaks in the earths crust, dying animal debris, scuttled ships, garbage thrown overboard from Naval ships, Pleasure crafts, etc..........from oil spills, soil run off, foreign items swept out to sea due to hurricanes, etc, etc, etc.............. there just is no way to calculate or even guess how much garbage there may be at the bottom of the sea.

- Q: Can plastic sheets be used for greenhouse siding?

- Yes, plastic sheets can be used for greenhouse siding. They are commonly used due to their durability, affordability, and ability to provide insulation and UV protection for plants inside the greenhouse.

Send your message to us

PVC Foam Board Sheets - Plastic Sheets Manufacturer, Exporter and Supplier

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords