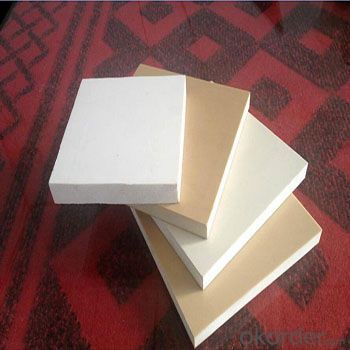

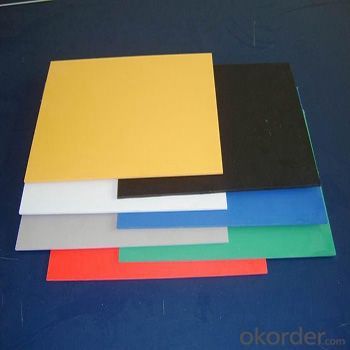

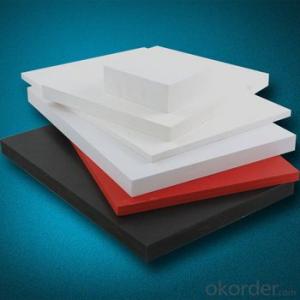

33mm UV Printing Plastic Sheets - PVC Foam Sheet/Board - Extruded Hard Rigid PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Production Capacity:10000pcs per month

Usage Life: more than 50 years

3.Features:

4.Application

1,8mm PVC foam board has characters like being soundproof,sound absorption,heat insulation, heat preservation

2,Our board has characters fire resistance, it can be self extinguishing ,can be used safely

3,It’s enviromental and nontoxic, does not include formaldehyde etc. harmful gas ,it can be called “Green products”

4,Different series products have moistureproof, zymosis proofing, no sob, shock proof effect is great

5,Different series product can be produced by weather resistance formulation , the color can stay long time ,and not easy to be aging

6,Our product is light and easy to storge and convinent to construct

7,Our product can be constructed by normal wood processing tools

8,It can be drilled saw, nailed, dig, glue etc. processing

9,It can be used for thermal forming, hot bending and foldig processing( besides fire-proof sheet)

10,It can be welded according to normal welding procesdures, also can be adhered with other PVC material

11,It is widely used in bathroom,kitchen,warehouse ect. Also can be used as Advertisement board,canbe printed on it

5.FAQ:

(1).How can i get the sample?

If you need samples, we can make as per your request. The samples available for free. And you should pay for the transportation freight.

(2).How long can i expect to get the sample?

The samples available as you ask in 1 days. The samples will be sent via express and arrive in 5~7 days.

(3).Can we have our Logo or company name to be printed on your package?

Sure. Your Logo can be putted on the package by printing or sticker.

(4).Can you cut the PVC foam board and in custom size?

Yes, we have facilities to cut the PVC foam board and mouldings in special sizes. If the size speciation is too complicated or the volume is too many, we will charge processing cost.

details:

- Q: What are the different ways to join plastic sheets together?

- There are several different ways to join plastic sheets together, including adhesive bonding, thermal welding, mechanical fastening, solvent welding, and ultrasonic welding.

- Q: I'm looking for a custom plastic covering that repels water and covers a safe (1mX 1m)P.S SHIPS TO CANADA

- Go to a place which makes covers for boats, or awnings and tents. Look in your yellow pages under upholstery. A place that sells foam for cushions and bedding may also do this kind of work.

- Q: the upper plastic sheet is bendable and the lower sheet is rigid. I need some type of glue that I could brush on easily to stick them together.. Since I may need alot of that glue, are there cheaper options for me?

- A spray adhesive will be your best bet. It will be the fastest and easiest and most cost effective considering the large quantity of items that you will be gluing. You will need an empty box to be your spray box so that you have a space to confine the over spray, and news papers to place in the bottom, enough to have on hand to put down on top of each other as a new clean surface after doing a few. I can suggest a brand called Super 77 Spray Adhesive or Elmer's Spray Adhesive. ***The Elmer's costs way less than the Super 77 (the Supper 77 is industrial strength stuff) Spray adhesives can be purchased at any home improvement stores, hardware stores, craft hobby stores as well as Walmart. I use spray adhesive all the time on a multitude of home crafting projects and it works on just about all surfaces. The only thing that it will do harm to is certain kinds of styrofoam, it will sometimes chemically melt that. But plastic surfaces will be just fine. I hope this helps you with your project! Good Luck!

- Q: Why is tarm paper or plastic sheeting put under hardwood floors?

- They are basically used as a vapor barrier to reduce the expansion/contraction of the floor. Tar paper will also cushion and quiet the floor just a little bit.

- Q: I like to play games now and then but my hands get sweaty when i play any game what makes at annoying to press buttons. (These have glossy finish which is basically gagging to be nice and slippery )is there an invisible stip of sticky plastic or something to put over the keys? any suggestion appreciated (:

- Gloves. going to look a litle silly, but itll do trick. no more sweaty keyboard, and saves you the hassle of looking for keyboard plastic protectors since you can buy gloves in your local department store.

- Q: Plastic gusset plate how to install the diagram?

- Main keel installation. The hanging distance of main keel should be selected according to the design. The middle part should be arched and the arch height of the keel should be no less than 1/200 of the span of the room. After the main keel is installed, correct the position and height in time. The vertical and horizontal elevation control line is drawn out, and the suspension height of the boom is adjusted from one end to the other, so as to control the formation of the keel. After the large surface has been leveled, the single keel with bent edges should be adjusted until it is smooth and meets the requirements. In the installation of the main keel, but also pay attention to leave the exit of the lighting line;

- Q: Can plastic sheets be used in medical applications?

- Yes, plastic sheets can be used in medical applications. They are commonly used for various purposes such as protective barriers, packaging, disposable equipment, and medical device components. Plastic sheets offer qualities like flexibility, durability, and resistance to chemicals, making them suitable for medical settings.

- Q: I am trying to imitate corrugated plastic (the translucent quality) but in a larger scale. Is there something you recommend I use? thanks!

- I have sprayed glass with a very light coat of cheap white spray paint, and it gives it the frosted look. I bet the same would apply to acrylic.

- Q: something thin to make cut-out necklaces from?

- If you're in California, Oregon, or Washington, look in the Yellow-Pages for TAP PLASTICS Company. I've been buying acrylic sheet, rod, and bar from them since the 1980's. Most Home-Depot type stores will also carry THIN acrylic sheet in both frosted and textured form for fluorescent light covers. I'm not quite sure what a cut-out necklace is, but you might also try a model-hobby shop which will carry thin styrene plastic sheet, tube, and rod. Styrene can be painted with enamel or acrylic paints in ENDLESS colors. GOOD Luck and wear safety glasses when cutting plastic !!

- Q: Are plastic sheets scratch-resistant?

- No, plastic sheets are not scratch-resistant. They can easily get scratched with sharp objects or rough handling.

Send your message to us

33mm UV Printing Plastic Sheets - PVC Foam Sheet/Board - Extruded Hard Rigid PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords