PVC Flex Banner Backlit Flex Banner Advertising Flex Banne

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of PVC Mesh Flex Banner Description

Flex PVC Inkjet Media is designed for use with solvent-based inkjet systems. The special surface coating optimizes ink adhesion and color reproduction for long-lasting brilliant prints. Backlit is a special translucent sign face material ideal for backlit displays offering a high printing quality when only printing a single strike image.

2. Main Features of the PVC Mesh Flex Banner

. High strength

. Weather resistant

. Waterproof

. Self-cleaning

. Good smoothness

. Perfect printing ability

. Best color fastness

. Gloss or Matt available

. Customer's requirement available

. Anti flame is available

Ink and Printer Support:

Suitable Ink: Solvent ink, Eco-solvent ink, UV ink.

Suitable printers: All kinds of wide format printing and inkjet printers, such as Vutek, Nur, Roland, Mutoh, HP- Scitex, Mmaki, Jeti etc.

Applications:

. Digital printing on Allwin Vutek, HP, Nur, Roland etc

. For large format indoor and outdoor advertising, banner, posters,

. Display (indoor or outdoor), airport light boxes, building murals,large format lights boxes

. Exhibition booth decoration, backlit shelters, etc.

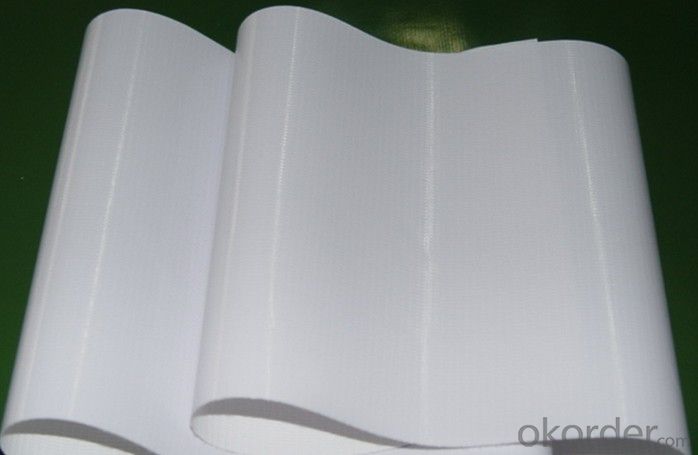

3. PVC Mesh Flex Banner Images

4. PVC Mesh Flex Banner Specification

-Durable material and printing

-Passed ISO 9001:2008 and SGS

-Weather Resistant

-Output 1000,000sqm

-Vivid printing and durable color.

-Used for indoor or outdoor cases.

-Professional design team help you to solve the artwork problems.

-High quality and competitve price.

-Promised after-sale service for PVC Mesh Flex Banner .

-Printed on durable, 13 oz. Gloss Vinyl for both outdoor and indoor use, with UV inks. CMYK inkset at 1000dpi.

-Free Super Saver Shipping to contiguous US States Air & 3 Day Services Available.

-PVC Mesh Flex Banner are finished with Hemmed Edges on all 4 sides & Metal Nickel Grommets placed along the top & bottom hems.

-Do not keep your vinyl banner in a humid or hot environment, and always store rolled up with the Graphics facing outward.

-If you are not 100% thrilled with your purchase, please let us know within 24 hours and we'll make it right.

No matter if we goofed in the process, or you goofed in your design, it's covered by the Baron's Goof Proof Guarantee.

5. FAQ of PVC Mesh Flex Banner

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in PVC Mesh Flex Banner, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. PVC Mesh Flex Banner cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: 1pc/polybag/tube, several pcs/CTN

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 2-3 business days to arrive your hand; When comes to the customs declaration, it may need 1 more day.

Other mass qty of PVC Mesh Flex Banner, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 15~40days, by air, it may need 5~8days.

- Q: What kind of material is plastic film in greenhouse?

- Multifunctional long-life filmMultifunctional long-life film is added in the process of aging of polyethylene material and amount of surfactants. Multifunctional film Zhejiang Xinguang plastic factory production, 7.5 meters wide, 0.06 mm thick, the service life of a times longer than ordinary film, other than the night shed material high 1 - 2 C. Moreover, the film is not easy to be filled with water drops, has good coverage effect, low cost and high benefit.

- Q: A concrete cover film, under what circumstances to cover, what does not cover

- The hydration heat of the cement requires only twenty percent of the actual water, and the rest will evaporateAll water evaporates to form a contraction

- Q: How to detect the surface tension of plastic film?

- A layer of ink used to bind a printed film with paper tape. The less the ink is stuck, the better it is treated. To peel off the bonded composite film, the greater the peel strength, the better the treatment effect.

- Q: What is the raw material of agricultural film?

- Agricultural film raw material is HDPE, commonly known as low pressure, buy this kind of raw material, the most important to see your demand, if the amount of big, you can directly find petrochemical agents.

- Q: What is concrete plastic sheeting for moisture conservation?

- Plastic cloth maintenance: plastic sheeting is used to cover the concrete surface, curing the concrete.

- Q: Can ultraviolet light penetrate transparent plastic film?

- Depends on what kind of material film, different film on ultraviolet absorption is not the same, and some can absorb all, and some can not

- Q: Why should a plastic film be affixed after the concrete has been poured?

- Direct point1, if the appearance of concrete can not hide the ugly2, water charges are too expensive, after cover, you can reduce or no watering seal supervision mouth

- Q: Is it good to use paper bags or plastic film bags?

- With asbestos mesh (general dish pack more use of this media) direct contact with the disk, the relative effect is better

- Q: What kind of plastic film is a little sticky and can be affixed to the label perfectly? What is it like a sticker?

- I'm afraid you don't have that. The mucosa is not expensive. When you run out of it, throw it away and change it again.

- Q: What is the working principle of the manual plastic bag sealing machine?

- Working principle of manual plastic bag sealing machine:Plastic bag sealing machine is suitable for aluminum foil bag, plastic bag, compound bag and ideal sealing machine in medicine, pesticide, food, daily chemical, lubricating oil and other industries. The sealing machine is designed and manufactured on the basis of the advanced models at home and abroad, as well as the function of vertical and horizontal sealing. Applicable to all plastic film sealing and bag making, food factory, cosmetics factory, pharmaceutical and other units of the ideal sealing equipment, continuous operation, but also according to user needs to date, batch number, etc.. Suitable for assembly line work.

Send your message to us

PVC Flex Banner Backlit Flex Banner Advertising Flex Banne

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords